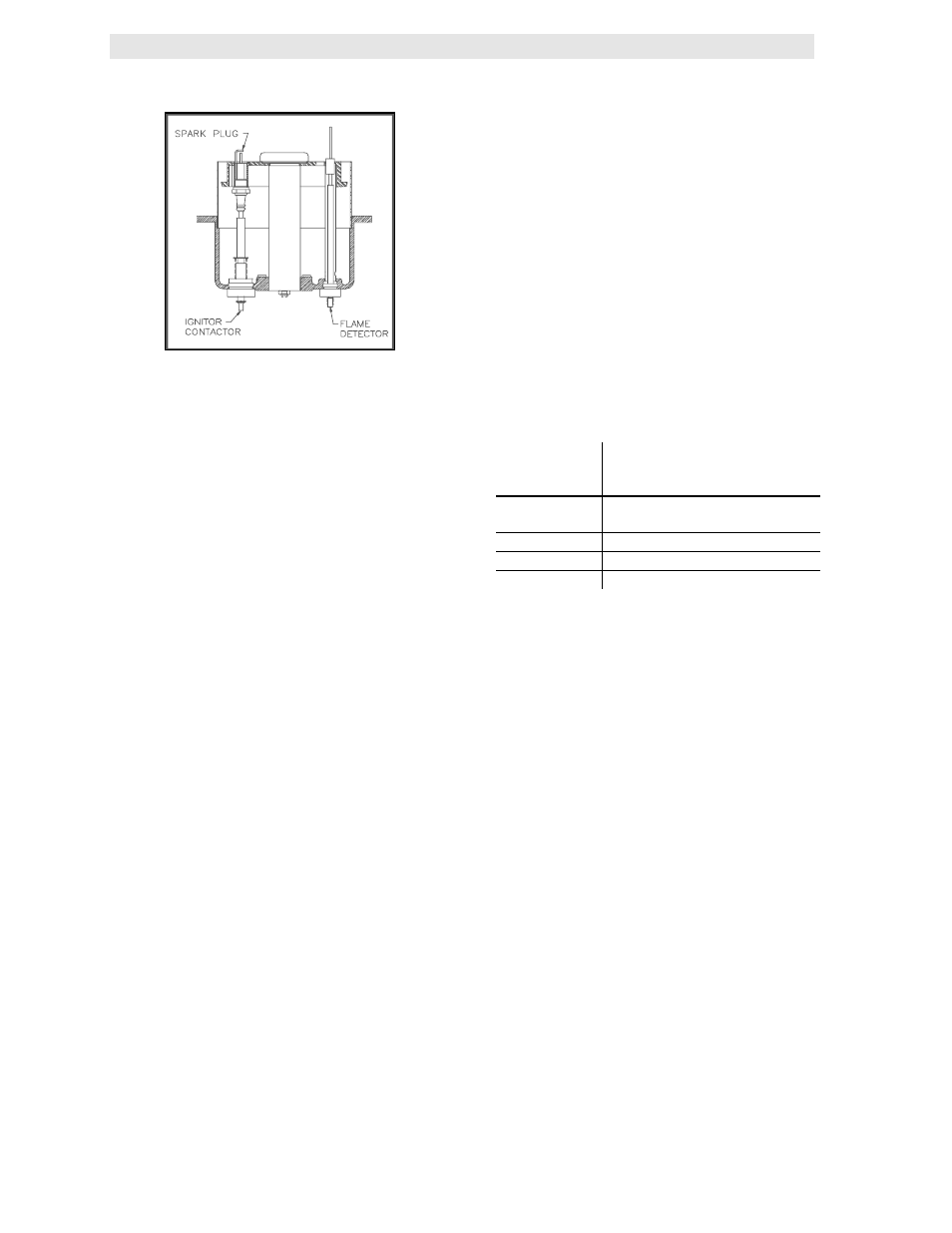

Figure 7.1, Spark ignitor and flame detector location, Maintenance – AERCO KC1000 Boiler equipped with Mod-Box Controller User Manual

Page 39

MAINTENANCE

34

Figure 7.1

Spark Ignitor and Flame Detector Location

To inspect or replace the flame detector:

1. Put the green ON/OFF button on the control

panel to the OFF position and disconnect AC

power to the unit.

2. Disconnect the plastic tubing from the

condensate cup to drain and remove the

rear covers from the unit. Access to the

flame detector may also be gained by

removing the unit’s left side panel

3. Disconnect the flame detector lead wire.

Unscrew the flame detector and remove it

from its guide tube. The detector is flexible

and may be bent to ease its removal.

4. Inspect the detector thoroughly. If eroded,

the detector should be replaced. Otherwise

clean the detector with a fine emery cloth.

5. Reinstall the flame detector hand tight only.

6. Reconnect the flame detector lead wire.

7. Replace the rear cover panels or left side

panel and reconnect the rear covers to the

unit. Replace the condensate cup to drain

tubing.

7.4 COMBUSTION CALIBRATION

Combustion settings must be checked at the

intervals shown in Table 1 as part of the

maintenance requirements. Refer to Sections

4.2 and 4.3 for combustion calibration

instructions.

7.5 SAFETY DEVICE TESTING

Systematic and thorough tests of the operating

and safety devices should be performed to

ensure that they are operating as designed.

Certain code requirements, such as ASME CSD-

1, require that these tests be performed on a

scheduled basis. Test schedules must conform

to local jurisdictions. The results of the tests

should be recorded in a log book. See Section 6-

Safety Device Testing Procedures.

7.6 MANIFOLD AND EXHAUST TUBES

The presence of even trace amounts of

chlorides and/or sulfur, in the combustion air and

fuel sources, can lead to the formation of

deposits on the inside of the exchanger tubes,

the exhaust manifold, and/or the condensate

cup. The degree of deposition is influenced by

the extent of the condensing operation and the

chloride and sulfur levels that vary significantly

from application to application.

The following parts will be necessary for

reassembly after inspection:

GP-122537

Exhaust Manifold to

Combustion Chamber

Gasket

GP-18900

Manifold to Tubesheet

Gasket

GP-18899 Burner

Gasket

GP-122551

Burner Release Gasket

*GP-161151

Combustion Chamber Liner

*Not necessary to change but should be on hand

in case damage occurs during the inspection.

To remove the manifold for inspection:

1. Disconnect AC power and turn off the gas

supply to the unit.

2. Remove the sheet metal covers from the

unit.

3. Disconnect the plastic tubing from the

condensate cup to drain and remove the

rear covers.

4. Remove the condensate cup from under the

unit and the condensate drainage tubing

from the manifold.

5. Remove the flame detector and ignition

cable wires from the flame detector and

ignitor contactor. Remove the flame detector

and ignitor as sections 7.2, and 7.3.

6. Remove the grounding terminal from the

burner by loosening the upper screw and

sliding the connector from the grounding rod.

(See Fig. 7.2)