Iinstalling l-cells – Kistler-Morse KM L-Cell Bolt-On User Manual

Page 48

Chapter 5. L-Cell Installation on Skirt-Supported Vessels

5-11

Note: Use industrial-grade, heavy-duty tapping fluid when

drilling and tapping.

Surface Preparation

1.

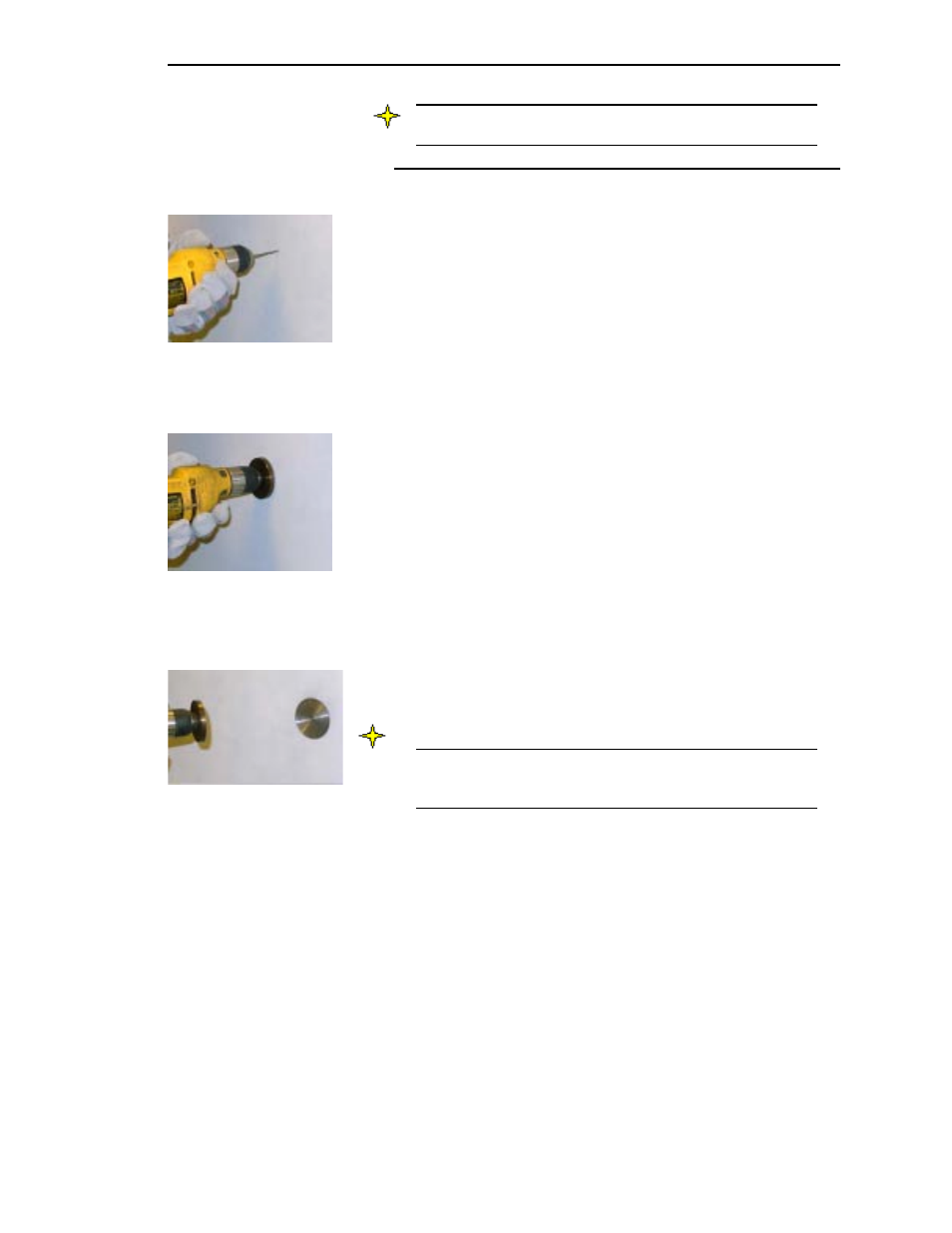

See Figure 5-16. At the center of the previously marked mounting

location for the outside L-Cell, drill all the way through the skirt

with the #36 drill bit. This produces the template mounting hole.

2.

Peel the backing off the coarse (36) grit sander disk and press the

sander disk onto the surfacing disk. Using the template mounting

hole as a tool center, remove heavy paint and rust with the

drill-mounted surfacing disk until a 2.50” (63.5mm) diameter bare

metal surface is achieved (Fig 5-17)

• Use straight, constant pressure. Do not roll or rock the grinding

disk as this will cause a ‘cupped’ surface.

The goal is to grind a flat surface for mounting the L-Cell.

• Due to the use of coarse grit, the resulting surface is somewhat

coarse.

3.

Replace the coarse grit with the fine (60) grit sander disk. Using the

template mounting hole as a tool center, grind until the surface is

flat and smooth to the touch. This results in a 2.50” (63.5mm)

diameter surface where the L-Cell will be mounted. (Fig 5-18)

Note

The L-Cell must be mounted against smooth, bare metal. All

paint and rust must be removed from the area where the L-Cell is

to be fastened.

4.

Repeat Steps 1 through 3 to prepare the surface on the inside of

the skirt before proceeding with L-Cell installation.

I

Installing L-Cells

Figure 5-16. Drill

Mounting Hole

Figure 5-17. Prepare area

with Disc Sander

Figure 5-18. Use finer

grit sander disc.