L-cell mounting methods – Kistler-Morse KM L-Cell Bolt-On User Manual

Page 28

Chapter 4. L-Cell Installation on Horizontal Beams

4-3

L-Cell Mounting Methods

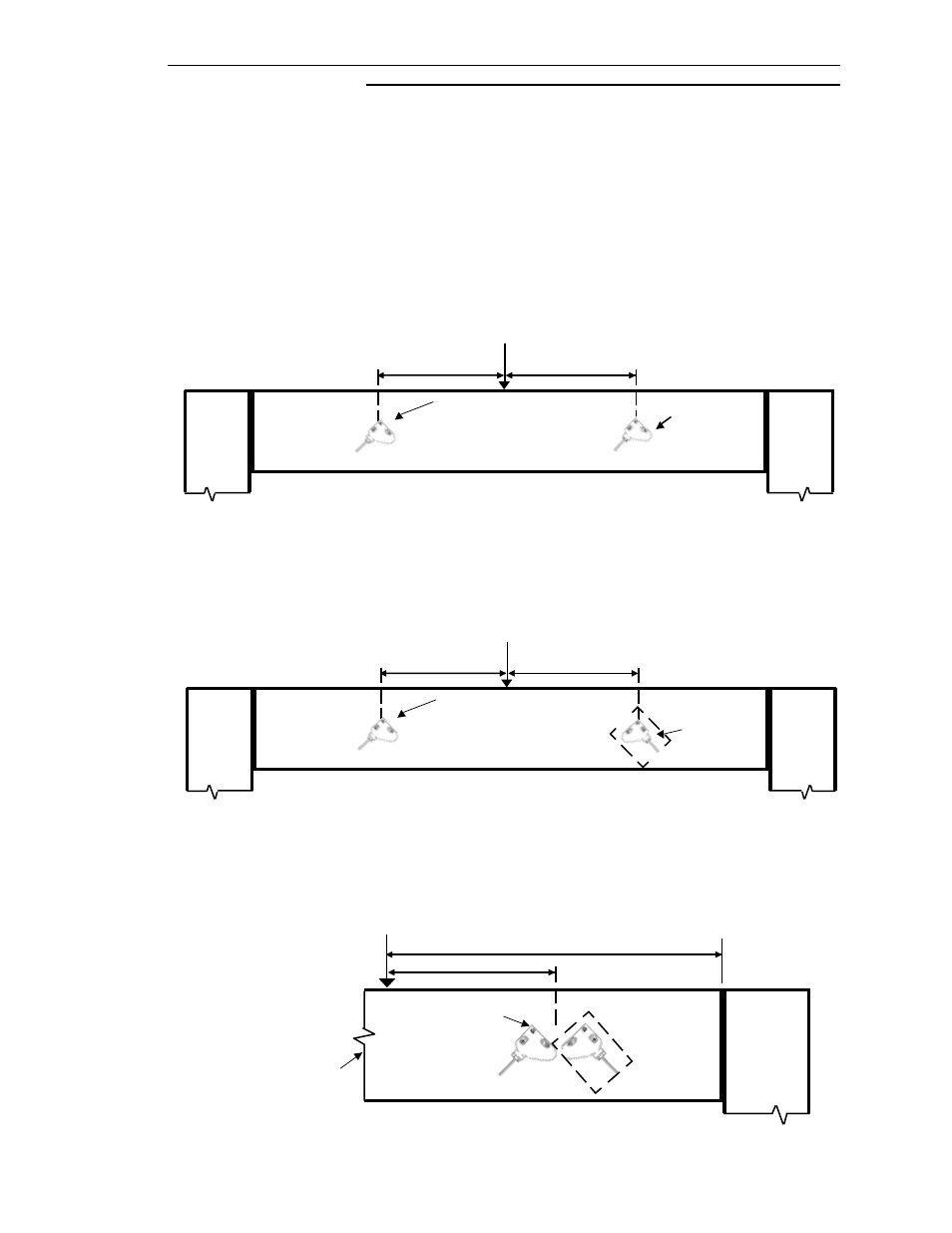

The sensors are mounted at the neutral axis on the web of the beam, at a

45-degree angle, halfway between the loading point and the support point.

The following methods provide varied degrees of accuracy.

I. Same Side: One L-Cell to the left and one L-Cell to the right of the load

point equidistant between the load and the support. The L-Cells are

mounted on the same side of the web. The excitation of the L-Cell to the

right of the load point must be reverse wired (See page 4-8). This arrange-

ment provides average accuracy performance.

II. Opposite Side: One L-Cell to the left and one L-Cell to the right of the

load point equidistant between the load and the support. The L-Cells are

mounted on opposite sides of the web. This arrangement provides average

accuracy performance.

III. Back-to Back: Two L-Cells mounted back-to-back on the web. They can

be mounted beck-to-back on either side of the load point, equidistant

between the load and the support. This arrangement provides average

accuracy performance.

Figure 4-3. Placement of Two L-Cells on same side of web

Load Point

Top of L-Cell Point

Toward LoadPoint

A

B

Reverse

wired

Figure 4-4. Placement of Two L-Cells on opposites of web

Load Point

Top of L-Cell Point

Toward LoadPoint

A

B

Opposite

side of

beam

Column

(or beam)

Supporting

Instrumented

Beam

Load Point from

Vessel or End of

Diagonal Beam

Two L-Cells

back-to-back

Horizontal or

Diagonal Beam

1

/

2

L

L = Distance from Load Point to Column or Beam Support

Minimum of 18” (457mm)

or beam height

Figure 4-5. Placement of Two L-Cells back-to-back