I.c.c. setting – KEYENCE SJ-M201 User Manual

Page 11

11

3-4

Other Functions

■ Relationship between installation distance and static elimination speed

according to air flow rate

The relationship between static elimination

speed and installation distance between the

Static Elimination Head varies according to

the air flow rate.

Select an air supply flow rate by referring to

the typical example on the right.

Measurement conditions:

Static elimination time from +1000V to +100V

range

150 mm x 150 mm plate monitor (20 pF)

used

0.00

0.50

1.00

1.50

2.00

2.50

3.00

4.00

3.50

0

150

250

50

100

200

Installation distance (mm)

Static elimination speed (secs)

20NL

60NL

250NL

SJ-M021

0.00

1.00

2.00

3.00

4.00

5.00

6.00

8.00

7.00

0

150

250

50

100

200

20NL

40NL

160NL

Installation distance (mm)

Static elimination speed (secs)

0.00

1.00

2.00

3.00

4.00

5.00

6.00

8.00

7.00

0

150

250

50

100

200

20NL

60NL

250NL

Installation distance (mm)

Static elimination speed (secs)

0.00

1.00

3.00

5.00

7.00

9.00

11.00

15.00

13.00

0

150

250

50

100

200

60NL

140NL

250NL

Installation distance (mm)

Static elimination speed (secs)

0.00

1.00

3.00

5.00

7.00

9.00

11.00

15.00

13.00

0

150

250

50

100

200

20NL

60NL

250NL

Installation distance (mm)

Static elimination speed (secs)

SJ-M021+SJ-MS1

SJ-M021+SJ-MS2

SJ-M021+SJ-MS3 tube 500 mm

SJ-M021+SJ-ML

3-4

Other Functions

■ Relationship between installation distance and wind speed according to air

flow rate

The relationship between wind speed and static elimination head installation distance varies

according to the air flow rate.

Adjust the air supply flow rate by referring to the following figures.

75

100 150 200 250 300 350

50

0

400mm

mm

50

25

0

-25

-50

-75

10m/s

2m/s

1m/s

75

200 300 400 500 600 700

100

0

1000mm

mm

50

25

0

-25

-50

-75

800 900

10m/s 5m/s

1m/s

2m/s

100

200 300 400 500 600 700

100

0

1500mm

mm

50

75

25

0

-25

-50

-75

-100

800 900 1000 1100 1200 1300 1400

10m/s

20m/s

5m/s

1m/s

1m/s

2m/s

2m/s

Air flow rate: 250 Nl/min (pressure 0.5 MPa)

Air flow rate: 20 Nl/min (pressure 0.01 MPa)

Air flow rate: 60 Nl/min (pressure 0.08 MPa)

3-4

Other Functions

■ How to supply air

Supply air from the SJ-M021(G)'s Air Input Unit as shown in

the figure on the right.

Joints and tubes must be prepared separately.

●

Recommended joint

We recommend using a tube fitting (tube dia. 6 mm, 8 mm) made by PISCO for a joint to the Air Input

Unit.

Rc1/8

Tube

• Be sure to limit the tightening torque to 0.7 Nm. Tightening beyond this

limit may cause an accident or a malfunction.

• Use clean air, without dust or oil mist, when measuring. (When

compressed air is used, air that conforms to ISO class of 1.1.1 through 1.3.1

is allowable.)

Class rate of compressed air indicated by ISO 8573-1

* Water content values shown in the bracket indicates the dew point temper-

ature at atmospheric pressure.

E.g. The “Class 1.3.1” indicates the rating of 0.1 μm of the solid particle.

-20°C of dew point under the pressure and 0.01 mg/m

3

oil density.

Tube dia.6 mm: PC6-01

Tube dia.8 mm: PC8-01

CAUTION

Class

Maximum particle

size (μm)

Water content (Pressure dew

point temp. at 0.69 MPa)

Remained oil

(mg/m

3

)

1

0.1

-70 (-83)

0.01

2 1

-40

(-58)

0.1

3 5

-20

(-42)

1

3-4

Other Functions

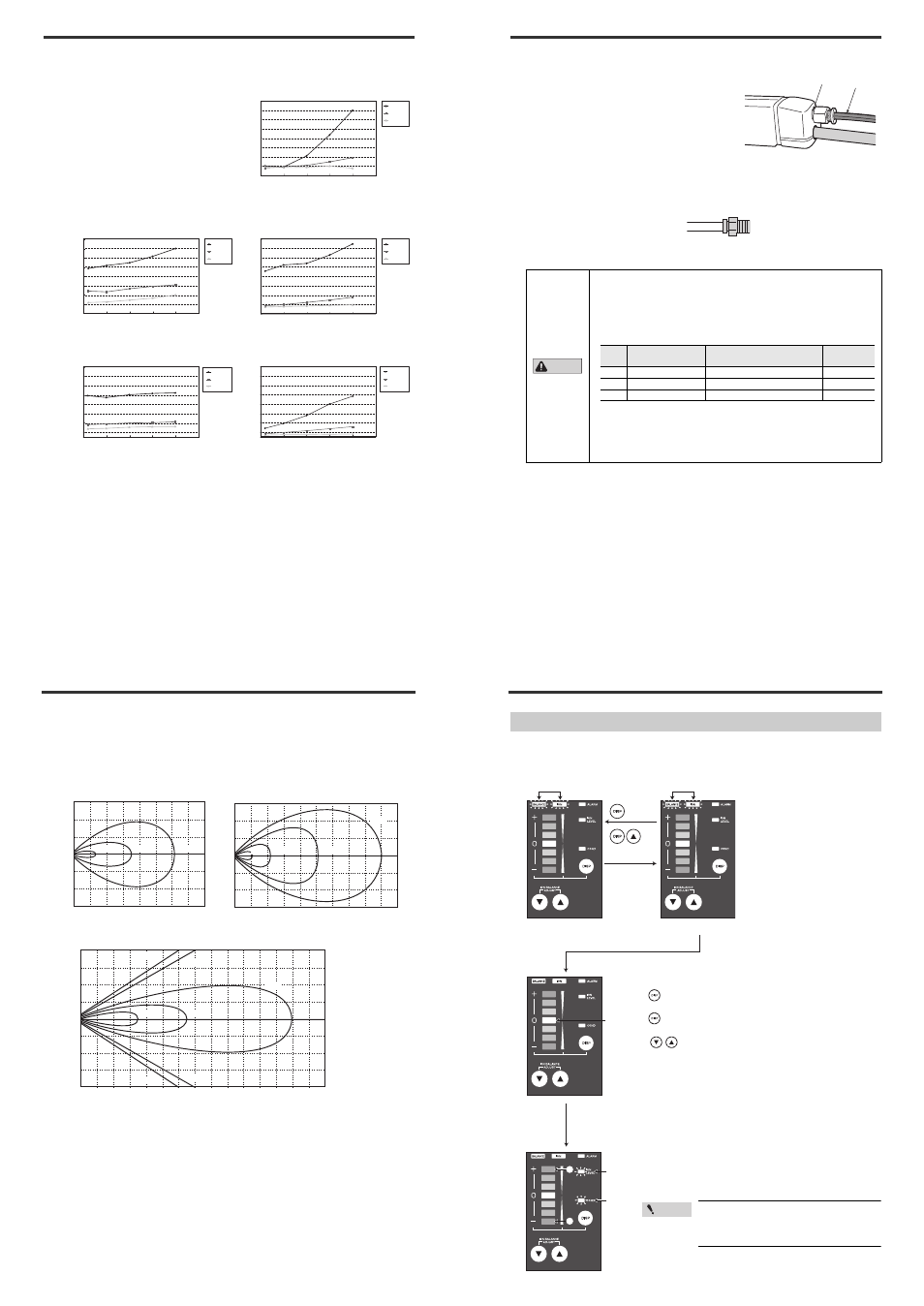

I.C.C. Setting

The I.C.C. (Ion Current Control) can be turned on and off.

Turning off the I.C.C. allows the ion balance adjustment function to generate positive and negative

ions at a fixed ratio.

Either is lit

Blink alternately

Hold down

for at least

1 second

Hold down for at

least 1 second

simultaneously

Change

Change

Change

Blink

Blink

Change the 4th LED from the top in the Setup mode.

Press for a short time

: advances to the Setup mode

of the selected item

Hold down for at least 1 second: exits the Setup mode and

returns to the Run mode

: moves the cursor up and

down

On the ion monitor, the currently selected items are lit in green and the

items whose default have been changed are lit in red.

I.C.C. is set at ON by default setting.

Items that satisfy both of these conditions blink in red and green

alternately.

Advance to the I.C.C. ON/OFF setting from the Setup mode in page 8,

and select either of the following:

(1) I.C.C. ON (Default)

(2) I.C.C. OFF

Select an appropriate nozzle according to the

head. Incorrect setting may cause accidents or

malfunction. When I.C.C. function is off, the ion

level alarm will not be output correctly.

Point