2 ion monitor functions, Ion monitor functions, 3 alarm output functions – KEYENCE SJ-M201 User Manual

Page 10: Alarm output functions, 4 other functions, Abnormal discharge detection function, Static elimination stop function, Air purge function, Other functions

10

3-2

Ion Monitor Functions

This section describes the ion monitor functions of the SJ-M Series.

Ion monitor functions are enabled in the Run mode.

Ion Monitor Functions

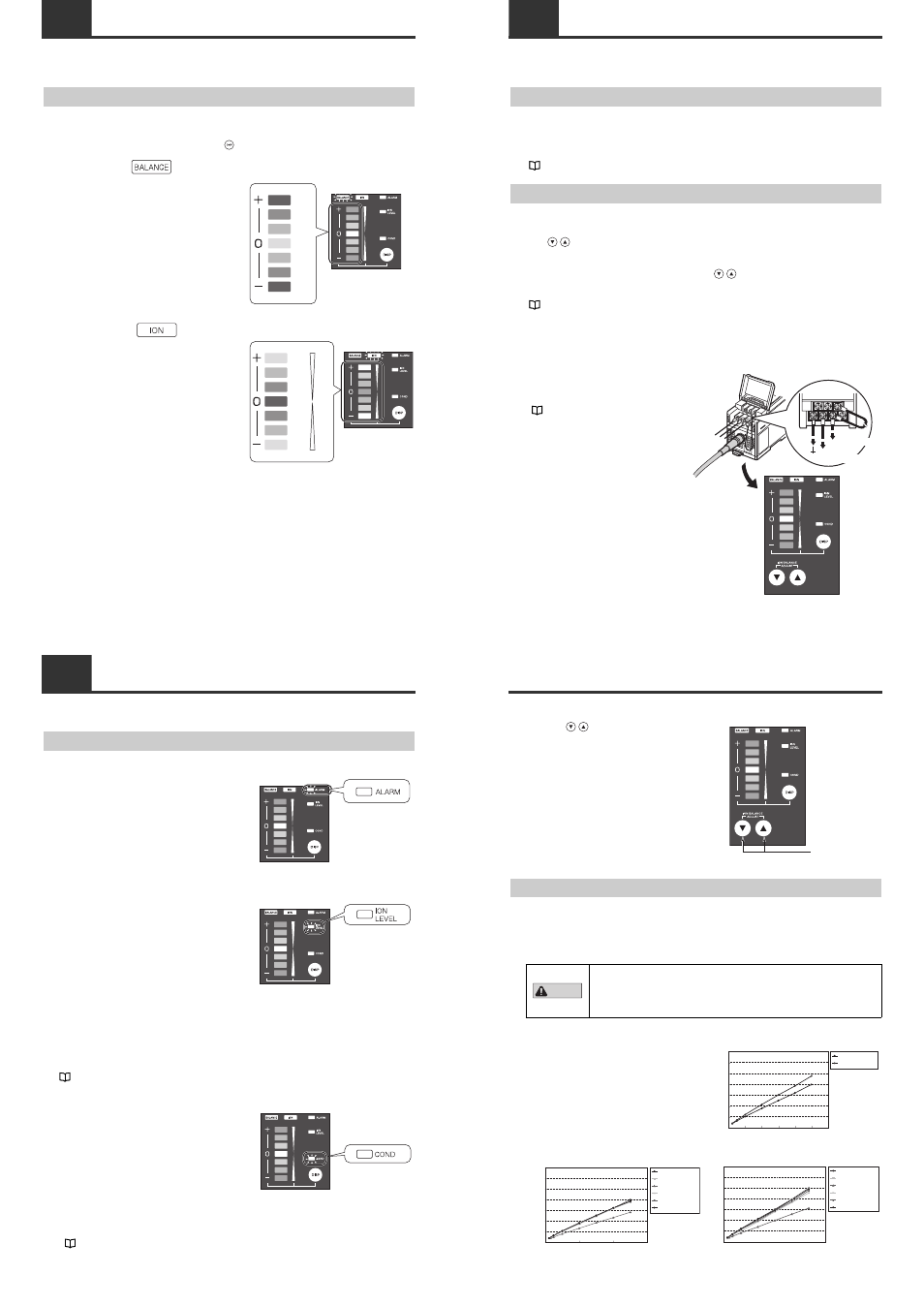

The charged level of the target object and the level of ions generated from the static elimination head

are indicated on the ion monitor.

The ion monitor indication can be switched by

.

■ Charge monitor

This monitor indicates the charged state of the

target object.

The indication of this monitor fluctuates towards the

+ and – sides according to the charged level. The

further the indication is away from the center LED,

the larger the charged level. When static

elimination is completed, the indication returns to

the center LED so that you can easily tell how static

elimination is progressing.

The ion balance indicator lights when the charge

monitor is operating.

■ Ion level monitor

This monitor indicates the level of ions being

generated by the Static Elimination Head.

The level of plus ions being generated is indicated

on the upper side, while the level of minus ions is

indicated on the lower side. The further the

indication is away from the center LED, the larger

the level of ions. In a state where ions are being

sufficiently generated, both ends of this monitor

light (green).

The ion balance indicator lights when the ion level

monitor is operating.

Red

Orange

Orange

Green

Orange

Orange

Red

Green

Green

Orange

Red

Orange

Green

Green

Max.

+ ion

Min.

Min.

- ion

Max.

3-3

Alarm Output Functions

This section describes the alarm output functions of the SJ-M Series.

Alarm Output Functions

■ Alarm output function (ALARM)

The alarm indicator blinks (red) and an alarm signal

(control output (N.C.)) is output, for example, when

internal circuits are damaged or abnormal

discharging occurs. When an alarm signal is output,

static elimination is forcibly stopped.

Alarm output turns ON even in a static elimination

stopped state (including forced static elimination

stop).

■ Ion level alarm output function (ION LEVEL)

The ion level alarm indicator lights and an alarm

signal (control output (N.O.)) is output when the level

of generated ions drops due to a dirty or worn

electrode probe, for example. When an alarm signal

is output, static elimination is not stopped.

The alarm output can be adjusted in three stages,

according to the level of ions generated.

The default setting for the ion level alarm sensitivity

setting is Low.

The ion level alarm serves as a guideline for learning

when to perform maintenance on the electrode probe.

As static elimination is continued, be sure to turn the

power OFF before starting maintenance on the

electrode probe.

The ion level alarm output function is enabled in the

Run mode.

"Ion level alarm sensitivity setup" (page 8)

■ Condition alarm output function (COND)

The condition alarm output indicator lights and an

alarm signal (control output (N.O.)) is output when

static elimination performance is influenced by an

excessive charge on the target object. When an

alarm signal is output, static elimination is not

stopped.

Alarm output can be adjusted in three stages

according to the installation environment. The default

setting for the condition alarm sensitivity setting is

Low.

The condition alarm output function is enabled in the

Run mode.

"Condition alarm sensitivity setup" (page 8)

3-4

Other Functions

This section describes the abnormal discharge detection and static elimination stop functions of the

SJ-M Series.

Abnormal Discharge Detection Function

To prevent malfunction, the generation of ions is stopped when abnormal discharging, caused by

condensation on the electrode probe tips or adhesion of debris, for example, is detected. At this time,

the alarm indicator and ion monitor blink to inform you that an abnormality has occurred. For details of

the indicated state on the Controller Unit (operation/display section), see "During an alarm (level 2)"

(

page 15).

Static Elimination Stop Function

Static elimination only can be turned OFF in a powered ON state by two methods: by shorting the

static elimination stop input and 0V terminals on the Controller Unit (I/O terminal section), or by holding

down

on the Controller Unit (operation/display section) simultaneously for about three

seconds.

When the static elimination stop input has been performed on the Controller Unit (operation/display

section), this state can be canceled by holding down

simultaneously for about three seconds.

For details on indication states on the Controller Unit (operation/display section) when static

elimination stop input is canceled, see "Static elimination stop input (operation/display section)"

(

page 15).

■ Static elimination stop input

Static elimination is stopped by either of the following methods.

By operation on the Controller Unit (I/O terminal section):

Short the static elimination stop input and 0V

terminals to stop static elimination.

The center LED of the ion monitor blinks (red).

"Controller Unit (I/O terminal section)" (page

4)

To 24 VDC

power supply

To 24 VDC

power supply

3-4

Other Functions

By operation on the Controller Unit (operation/display section):

Hold down

simultaneously for about three

seconds to stop static elimination.

The three center LEDs of the ion monitor blink

(red).

Air Purge Function

Clean, dry air must be supplied to the SJ-M021(G) from the Air Input Unit. The air purge performs two

roles. It prevents dirt from sticking to the electrode probe and extends the static elimination area.

* The pressure value at the neck of the air duct is indicated as the air pressure.

Use clean, dry air of temperature –25°C, and a filter of mesh size of about 0.01 μm.

■ Relationship between air press and flow rate

The figure on the right shows the relationship

between the flow rate and pressure of the

supplied air.

Select an air compressor having sufficient

flow rate capacity by referring to this figure.

Hold down for

at least 3 seconds.

• Be sure to limit the air pressure to 0.5 MPa. Exceeding this limit may cause

accidents or malfunction.

• Be sure to use clean, dry air for supplying to the Static Elimination Head.

Moisture, oil, or nitrogen contained in the air may cause discharge inside

the Static Elimination Head, which may result in accidents or malfunction.

CAUTION

0

50

100

150

200

250

300

350

0

0.2

0.4

0.1

0.3

0.5 0.6

Air pressure [MPa]

Supply flow rate [NL/min]

SJ-M021G

SJ-M021

By model

0

50

100

150

200

250

300

350

0

0.2

0.4

0.6

SJ-M021G

SJ-M021G+SJ-MS2

SJ-M021G+SJ-MS1

SJ-M021G+SJ-MS3

SJ-M021G+SJ-MS4

SJ-M021G+SJ-ML

Air pressure [MPa]

Supply flow rate [NL/min]

0

50

100

150

200

250

300

350

0

0.2

0.4

0.6

SJ-M021

SJ-M021+SJ-MS2

SJ-M021+SJ-MS1

SJ-M021+SJ-MS3

SJ-M021+SJ-MS4

SJ-M021+SJ-ML

Air pressure [MPa]

Supply flow rate [NL/min]

By nozzle type (SJ-M021G)

By nozzle type (SJ-M021)