Ok ng, Thickness measurement setting methods, Preparation and overview – KEYENCE LK-G5000 Series User Manual

Page 12

12

Thickness Measurement Setting Methods

When two sensor heads are connected to measure thickness between the two sensor heads, the setting method is as follows.

With measurement between two sensor heads, it is possible to minimise the influence of vertical vibration.

Preparation and Overview

Required Components

No. of units

LK-G5000 Series controller

1

LK-G5000 Series sensor head

2

LK-G5000 Series head cable

2

LK-Navigator 2 configuration software

1

24 V power source

1

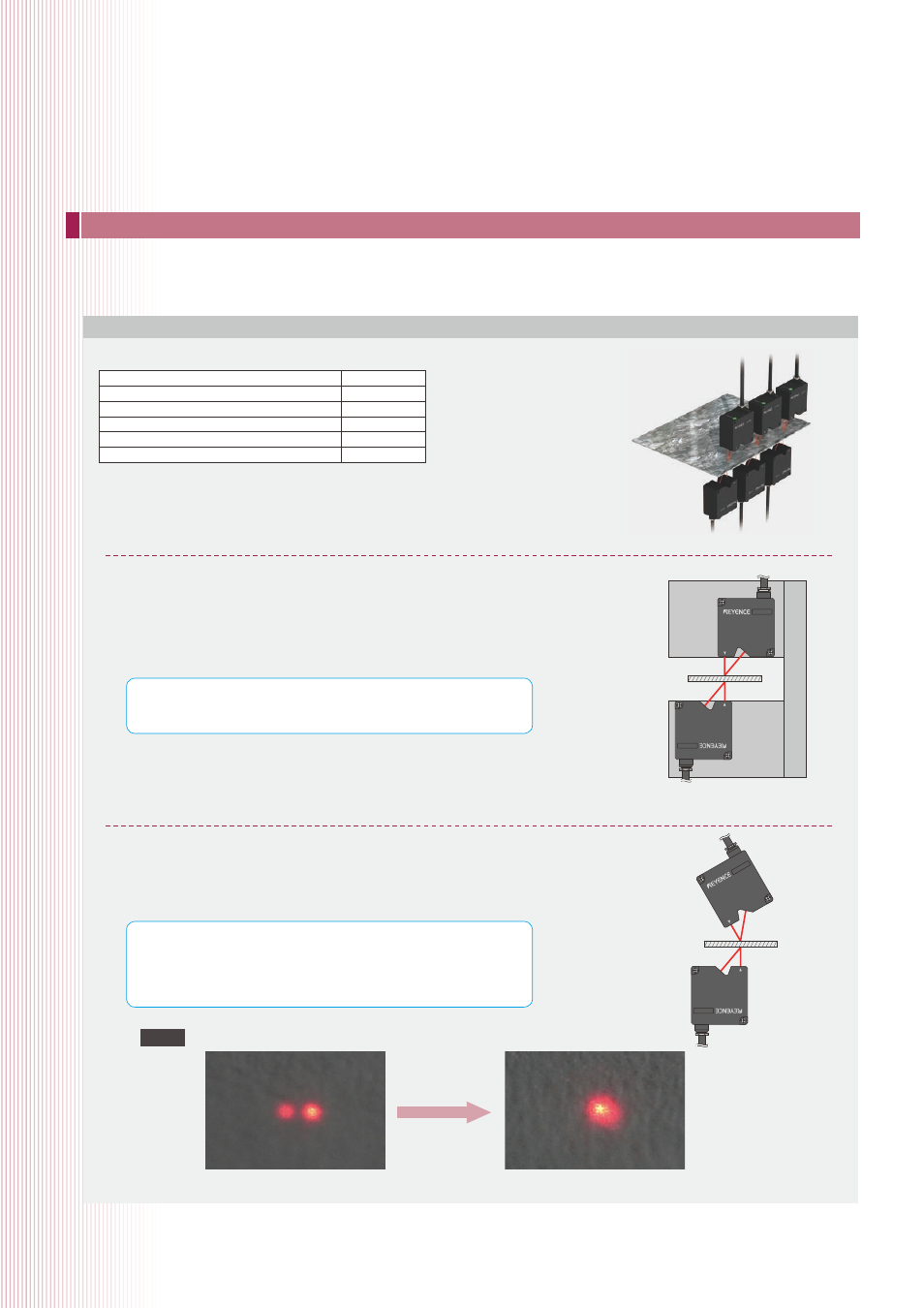

1. Sensor head mounting bracket

2. Adjusting the optical axis.

In order to perform measurement between two sensor heads, mount

the sensor heads as seen in the figure on the right. Once the target

has been inserted, mount the sensor head so that the surface of the

target comes to the standard distance for each head.

The optical axis for two sensor heads is adjusted to form a single

straight line. Adjust the optical axis so that the relative spot position

does not deviate even if the target is moved up and down.

Reverse-C-shaped single-body jig

OK

NG

As seen in the image on the right, a reverse-C-shaped single body jig can

reduce the influence of vibration in the mounting bracket.

Use a thin, white coloured plastic or piece of paper as a setup tool. These

types of materials will allow the user to see both the top and bottom spot

simultaneously. Sensor head position should be adjusted so that the beam

spots appear to overlap at all points in the measurement range.

The laser spots are slightly misaligned

Modify target installation so that the centres of

the laser spots overlap to form a single

The laser spots are

overlapping

Check that the top and bottom spots are properly overlapped even if the target is moved up and down.

USEFUL TIP

USEFUL TIP

Note