Calibration setting mode, Error message, Specifications – KEYENCE GT-70A Series User Manual

Page 9: Sensor head

9

GT-M-E

■

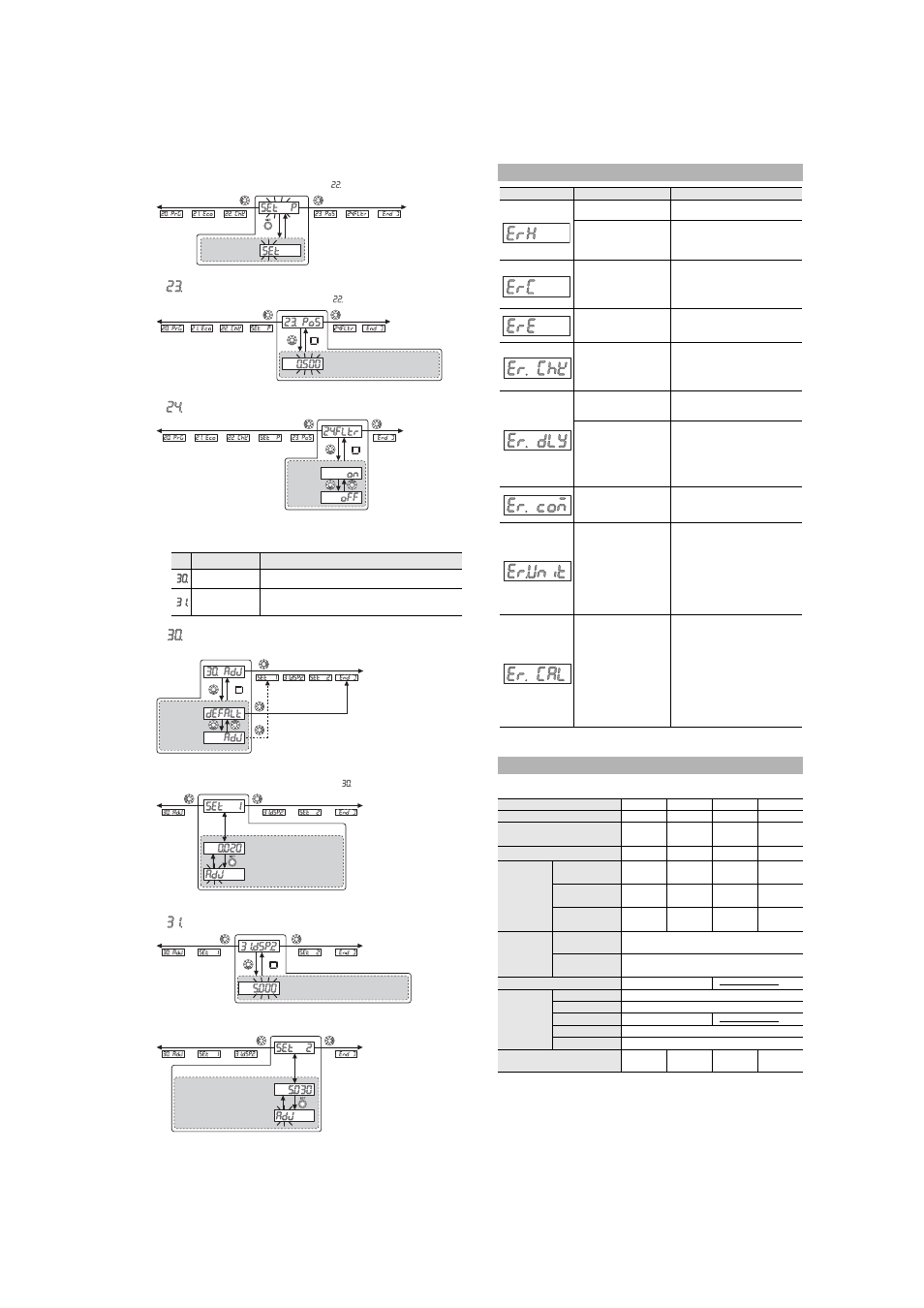

Calibration setting mode

You can set the following functions in the calibration setting mode.

Error message

*1 If not recovered by this action, there may be a possibility of failure or

permanent damage. In this case, change the amplifier unit.

Specifications

■

Sensor head

*1 The read value at the detection center under an ambient temperature

of 23°C and a response time of 100 ms (default state).

*2 At the center of the movable range of the sensor head installed.

Varies according to the mounted condition of the dust protective boot.

*3 The connector cable (2 m) is included.

No.

Item

Description

Calibration

Set the calibration function.

2nd point

target value

Set the target value of the span adjustment

(2nd point).

Reference position

fixed

Jam detection teaching

Available to set when USEr is selected in [ Jam detection function].

Check point setting

Display for entering the setting value

MODE

Available to set when USEr is selected in [ Jam detection function].

ON

Display filter function

OFF

MODE

Default

Adjustment

Calibration function setting

(press and hold the [MODE] + right buttons in the main screen)

MODE

Detect 1st point

Blink alternately

Capture the detection value

1st point detection/capture

Available to set only when AdJ is selected in [ Calibration function setting].

*Target value for the first point is the PrESEt value.

Display for entering the setting value

2nd point target value setting

MODE

Detect 2nd point

Blink alternately

Capture the detection value

2nd point detection/capture

Error display

Cause

Corrective action

The sensor head

cable is disconnected.

Connect the sensor head to

the amplifier.

• The sensor head

cable is broken.

• The sensor head is

damaged.

Change the sensor head.

An overcurrent flows

in the output line.

• Check that the load is within

the rating.

• Check that the output line is

not contacting other lines and

frames.

Failed to write/read

data.

Reboot the equipment and

perform initial reset.

*1

Spindle movement is

not detected

• If something is caught in the

spindle, causing the spindle not to

move, change the sensor head.

• Check the external timing input.

(Press the SET button to reset.)

The value fell below (rose

above) the timing level

during the delay time.

Change the delay timer time

setting. (Press the SET button

to reset.)

When setting the

internal timing, detection

was completed when the

value fell below (rose

above) the timing level

before the criterion value

(P.V. value) is fixed.

The value should not fall below

(rise above) the timing level

before the criterion value is

fixed. Alternatively, lengthen

the static hold delay stabilizing

amplitude so that the criterion

value can be easily fixed.

Contact between the

amplifiers is lost.

After turning OFF the power,

check the connection between

the amplifiers.

In the case of using the

calculation function,

the number of the

expansion unit when

the power is turned ON

differs from the number

of the expansion unit in

the memory of the

main unit when the

calculation is set.

• Reset the calculation mode

or perform the initial reset of

the main unit.

• After turning OFF the power,

check the connections

between the amplifiers.

• When using the

reference difference

(rEF) calculation

function, an error

occurred in the main

unit.

• When using other

than the reference

difference (rEF)

calculation function,

an error occurred in

an expansion unit.

Check each main/expansion

unit for the cause of the error.

Model

GT-H10

GT-H22

GT-H10L GT-H22L

Detecting range

10 mm

22 mm

10 mm

22 mm

Mechanical response

(at an ambient temperature of 23°C)

10 Hz max. 8 Hz max.

7 Hz max.

5 Hz max.

Repeat accuracy

*1

3 µm

8 µm

3 µm

8 µm

Measuring

Force

*2

When installed

facing down

1.0 N

1.5 N

0.3 N

0.35 N

When installed

sideways

0.9 N

1.4 N

0.25 N

0.3 N

When installed

facing up

0.8 N

1.3 N

0.2 N

0.25 N

Environmental

resistance

Ambient

temperature

-10°C to +55°C

Relative

humidity

35 to 85%RH

Protective construction

IP67

Material

Main unit cover SUS430

Indicator

Polyalylate

Dust protective boot NBR

Contact point

SUS440C

Cable

PVC

Weight

*3

Approx.

115 g

Approx.

135 g

Approx.

115 g

Approx.

135 g