Mounting the sensor head – KEYENCE GT-70A Series User Manual

Page 4

4

GT-M-E

■

Mounting the sensor head

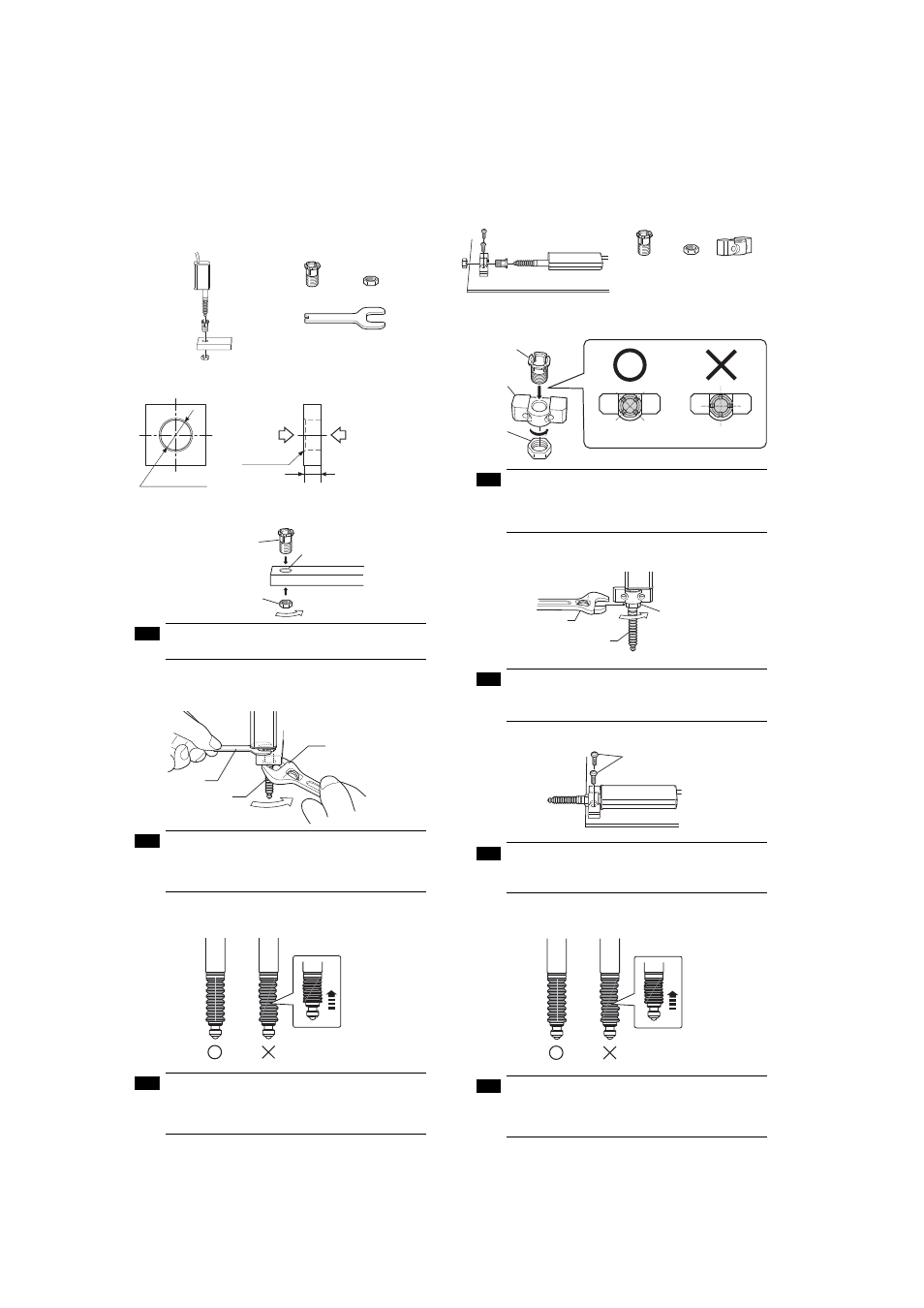

● Mounting directly to the jig

Before mounting the sensor head directory to the jig, create a hole

on the jig. Attach the sensor head using the optional Head mounting

bracket A (OP-76874).

1

Cut the jig to create a sensor head mounting hole referring to

the illustration below.

2

Insert the tightening sleeve into the hole (from the recessed

side), and loosely tighten with the nut.

Strongly tightening the nut without the sensor head

inserted may deform the tightening nut.

3

Insert the sensor head in the tightening sleeve. While securing

the tightening sleeve with the included key wrench, tighten the

nut with a separate wrench.

• Never apply tightening torque over 10 N•m

(The recommended tightening torque is 5 to 7 N•m).

• Care must be taken not to damage the dust protective

boot when tightening.

4

Rotate the dust protective boot so that the side line is straight.

Check with the spindle pushed in.

• If the dust protective boot is not straight, it becomes

easier to damage when the spindle is moved.

• If the end of the sensor head cable is bent repeatedly,

the cable may break.

● Mounting on the side of a surface

To mount the sensor head on the side face of a table, use the

optional Head mounting bracket B (OP-76875).

1

Insert the tightening sleeve into the mounting bracket from the

side with a depression, and loosely tighten with the nut.

• If the sleeve is inserted from the wrong side, the

sensor head cannot be secured.

• Strongly tightening the nut without the sensor head

inserted may deform the tightening nut.

2

Insert the sensor head into the tightening sleeve, and tighten

the nut with a wrench.

Never apply tightening torque over 10 N•m

(The recommended tightening torque is 5 to 7 N•m).

Use the wrench that fits the width of the nut.

3

Secure the sensor head with M4 screws.

• Never apply tightening torque over 1.4 N•m.

• Care must be taken not to damage the dust protective

boot when tightening.

4

Rotate the dust protective boot so that the side line is straight.

Check with the spindle pushed in.

• If the dust protective boot is not straight, it becomes

easier to damage when the spindle is moved.

• If the end of the sensor head cable is bent repeatedly,

the cable may break.

Tightening sleeve

Key wrench

Nut

Optional Head mounting

bracket A (OP-76874)

Mounting illustration

+0.005

+0.027

φ10 G8( )

Nut mounting side

C0.5 to C1.0

Tightening sleeve insertion side

5.5 to 11.3

Tightening sleeve

Nut

Recessed side

Note

Key wrench

Dust protective boot

Wrench

Note

Note

Mounting illustration

Tightening sleeve

Nut

Mounting bracket

Optional Head mounting

bracket B (OP-76875)

Tightening sleeve

Mounting bracket

Nut

Notice the correct angle of the tightening sleeve.

Note

Nut

Wrench

Dust protective boot

Note

M4 screws

Note

Note