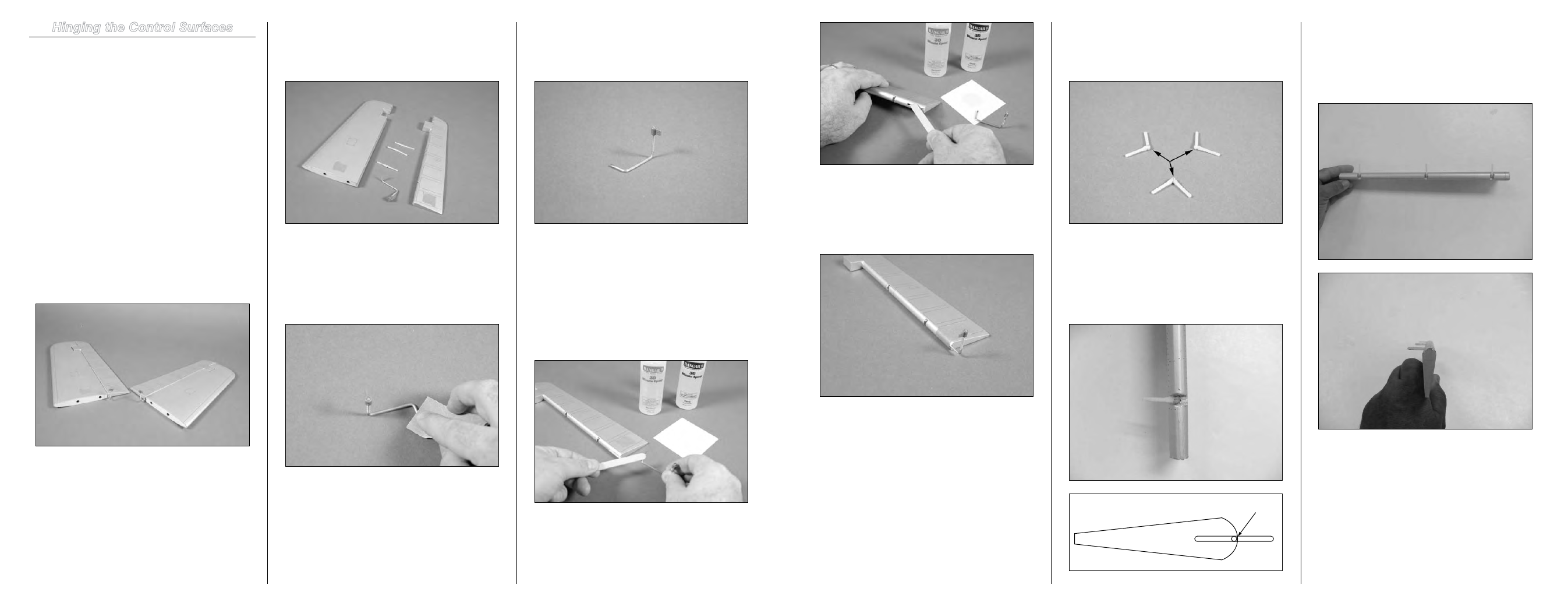

Hinging the control surfaces – Hangar 9 P-51D Blue Nose 60 ARF User Manual

Page 4

6

Hangar 9 P-51 Mustang 60 ARF Assembly Manual

7

Hangar 9 P-51 Mustang 60 ARF Assembly Manual

Step 6

Insert the wire into the hole in the elevator. Wrap a piece of

low-tack tape around the elevator to keep the wire secure

until the epoxy fully cures. While the epoxy cures we can

continue the hinging process then hinge the elevator last.

Step 7

Locate three hinges. Apply a small amount of petroleum jelly

to each hinge where it bends to prevent it from accidentally

being glued and preventing it from operating correctly.

Step 8

Insert the hinges into the control surface. Moving the hinge

over 90 degrees and pressing the hinge into the surface will

set the correct depth for the hinge, as the hinge point will

be recessed slightly in the control surface so it operates

properly.

Hinge point recessed in control surface

Step 9

In addition to setting the correct depth of the hinge, this will

guarantee that the hinge has been installed in the correct

direction. Rotating the hinge could cause the surface to bind,

increasing the load on the servo and draining the receiver

battery prematurely.

Hinging the Control Surfaces

Required Parts

Fuselage

Rudder

Hinge (3)

Wing panel with aileron and flap (right and left)

Stabilizer and elevator (right and left)

Elevator torque rod (right and left)

Tools and Adhesives

Hinge glue

30-minute epoxy

Sandpaper

Mixing stick

Low-tack tape

Paper towel

Rubbing alcohol

Petroleum jelly

Step 1

Locate the stabilizer and elevator assemblies. Note the

direction and location of the elevator control horn in

relationship to the stabilizer. It is suggested to use a small

piece of low-tack tape to mark one of the assemblies so the

elevator and stabilizer can be returned to their pairing.

Step 2

Separate the elevator and stabilizer. Remove the elevator

control horn and three hinges. Set the stabilizer and hinges

aside in a safe place.

Step 3

Use a piece of sandpaper to roughen the wire from the

elevator control horn where it contacts the elevator. This

provides a better surface for the epoxy to adhere to when

glued in position. Use a paper towel and rubbing alcohol to

remove any oils or debris from the wire after sanding.

Step 4

Thread the nylon horn on the wire so it is flush with the end

of the wire and facing the opposite direction of the portion of

the wire that will go into the elevator.

Note

: You can perform the following steps for both

elevator halves with one batch of epoxy. Read through

the steps to familiarize yourself with the procedure

before mixing any epoxy.

Step 5

Mix a small amount of 30-minute epoxy. Apply the epoxy to

the notch and into the hole in the elevator, as well as to the

portion of the wire that will contact the elevator.

Note

: Make sure to use enough epoxy to glue the

torque rods. If the epoxy does not ooze out between

the torque rod and elevator, you have not used enough

epoxy.