Hangar 9 P-51D Blue Nose 60 ARF User Manual

Page 10

18

Hangar 9 P-51 Mustang 60 ARF Assembly Manual

19

Hangar 9 P-51 Mustang 60 ARF Assembly Manual

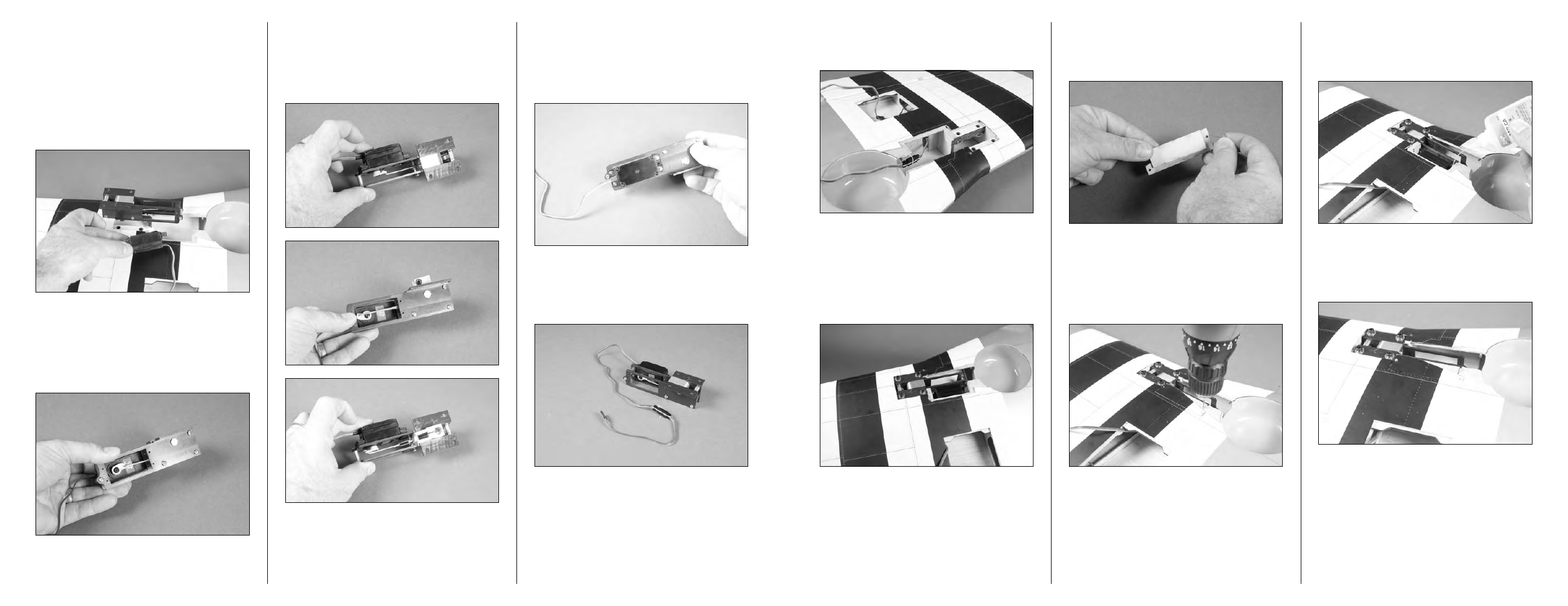

Step 10

Pass the extension through the hole in the wing behind the

opening for the retract mechanism.

Step 11

Position the retract mechanism into the wing. Use four

8-32 x 3/4-inch socket head screws and four #8 washers

to secure the retract mechanism in the wing. Tighten the

screws using a 9/64-inch hex wrench or ball driver. Make

sure to use threadlock on all four screws so they do not

vibrate loose in flight.

Step 12

Use a T-pin to poke through the covering of the retract

servo cover so the holes can be located from the top-side of

the cover.

Step 13

Position the retract servo cover over the retract servo. Slide

the cover back snug against the wing. Use a drill and 1/16-

inch (1.5mm) drill bit to drill the two holes for the cover

mounting screws. Use care not to drill through the top of the

wing when drilling these holes.

Step 14

Apply 2–3 drops of thin CA into each hole to harden the

surrounding wood. This provides a harder surface for the

screws making them more secure when installed.

Step 15

Secure the cover to the wing using two #2 x 3/8-inch

sheet metal screws. Tighten the screws using a #1 Phillips

screwdriver.

Step 5

Check to make sure you are installing the servo on the

correct side of the retract mechanism. The servo will face to

the trailing edge when installed.

Note

: The next steps will check the operation of the

retract mechanism. Do not secure the servo as poor

positioning of the linkage or servo could cause the

servo to bind causing stress on the radio battery or

even damage the servo gears.

Step 6

With the retract mechanism and servo in the “up” position,

check the fit of the servo in the retract frame. The mounting

holes of the servo must align with the holes in the frame for

mounting the servo. It may be necessary to adjust the length

of the linkage to get the mounting holes to align.

Step 7

Hold the servo in position against the retract frame. Check

the operation of the retract using the radio system. When the

retract mechanism is in the “down” position the mounting

holes should still be aligned. If not, the linkage may need

some more minor adjustments in length.

Important

: Also make sure the retract mechanism is

locking in both the “up” and “down” positions. If not, it

may be necessary to prepare a new servo horn with the

hole in a slightly different position.

Step 8

Once the retract is operating without binding and locking in

both the “up” and “down” positions, use four 2mm x 12mm

machine screws and four 2mm washers to secure the retract

to the retract frame. Use a 1.5mm hex wrench to tighten

these screws.

Step 9

Secure a 6-inch (152mm) servo extension to the retract

servo using string, dental floss or a commercially available

fastener.