Fuel tank installation, Electric motor installation – Hangar 9 P-51D Blue Nose 60 ARF User Manual

Page 26

50

Hangar 9 P-51 Mustang 60 ARF Assembly Manual

51

Hangar 9 P-51 Mustang 60 ARF Assembly Manual

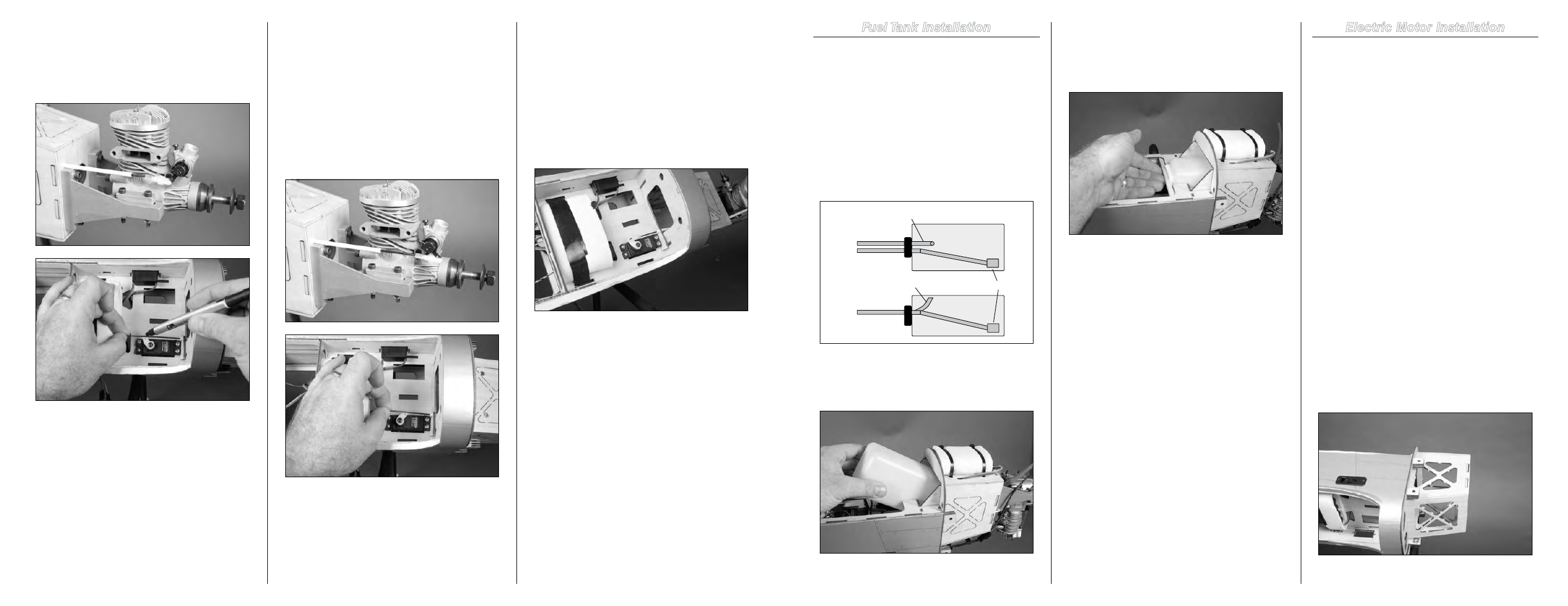

Fuel Tank Installation

Required Parts

Fuselage assembly

Fuel tank

Hardwood tank support

1/4-inch (6mm) foam

Tools and Adhesives

Medium CA

Step 1

Inspect the fuel tank so the lines inside the tank can be

identified. Note that the vent line in the tank will face to the

top of the fuselage when the fuel tank is installed.

Clunk

Vent Line

Top View

Side View

Vent Line (faces top of fuselage)

To Muffler

To Carburetor

Step 2

Slide the fuel tank in the fuselage. Make sure to guide the

tubes through the hole in the firewall.

Step 3

Cut the brace to length so it fits in the fuselage behind the

tank. Place a small piece of 1/4-inch (6mm) foam between

the brace and tank. Use medium CA to glue the brace in

position.

Electric Motor Installation

Required Parts

Fuselage assembly

Firewall template

#8 washer (8)

Motor with hardware

Electronic speed control

Aluminum motor standoff, 1

3

/

4

-inch (44.5mm) (4)

Tie wrap, 8-inch (205mm) (2)

8-32 x 3/4-inch socket head bolt (8)

Tools and Adhesives

Low-tack tape

Drill

Two-sided tape

Threadlock

Hex wrench or ball driver: 9/64-inch

Hobby knife with #11 blade

Hex wrench or ball driver: 2.5mm, 9/64-inch

Drill bit: 1/16-inch (1.5mm), 5/32-inch (4mm)

Note

: The motor shown installed in this section is the

Power 60. Installation of the Power 90 follows the same

procedure, but requires drilling the template in the

correct locations and the use of the 20mm Power 90

adapter placed between the firewall and the aluminum

standoffs.

Step 1

Use a hobby knife with a #11 blade to remove the plywood

filler pieces from the sides, top and bottom of the engine

box. This will allow air to flow into the fuselage to cool the

batteries.

Step 19

Use the radio system to move the throttle servo to the closed

position. Physically close the carburetor on the engine.

Make sure the direction of the servo and carburetor arm are

working in unison. Use a felt-tipped pen to mark the pushrod

where it crosses the outside hole of the servo arm.

Step 20

Use the radio system to move the throttle servo to the full

throttle position. Move the carburetor to the full throttle

position. Check that the mark on the pushrod wire aligns

with the outer hole of the carburetor arm. If it is off only a

slight amount, you can use the ATV function of your radio

to correct. If the line is too far forward, attach the clevis to

a hole on the servo arm that is closer to the center of the

servo. If it doesn’t move far enough, use a servo arm that

allows you to position the clevis farther from the center of

the servo. Repeat the previous steps if necessary to achieve

the correct amount of throw to operate the throttle on your

engine.

Step 21

Use pliers to make a 90 degree bend in the pushrod wire

where the mark was made in the previous steps.

Step 22

Enlarge the hole in the servo arm that works properly for

the operation of your throttle with a pin drill and 5/64-inch

(2mm) drill bit. Secure the throttle pushrod to the servo

horn using a pushrod keeper. Use medium CA to glue the

plywood pushrod support to the fuselage in a position that

will provide smooth movement of the throttle pushrod.