Hangar 9 P-51D Blue Nose 60 ARF User Manual

Page 13

24

Hangar 9 P-51 Mustang 60 ARF Assembly Manual

25

Hangar 9 P-51 Mustang 60 ARF Assembly Manual

Step 16

Use a hobby knife with a #11 blade to cut a 1/4-inch (6mm)

piece of tubing from the 2-inch (52mm) safety tubing

included with the kit. Slide the tubing on a clevis, and then

thread the clevis 10 turns on the flap pushrod.

Step 17

Slide the flap pushrod into the wing, bent end first. Connect

the clevis to the outer hole of the flap control horn. Slide the

safety tubing on the clevis so it won’t accidentally open in

flight.

Step 18

At this time you will want to mark the leads for the aileron,

retract and flap servos so each can be identified as they are

going to be hidden inside the wing. Tie the string around all

three leads and carefully pull them through the wing and out

through the hole.

Hint

: If you have a short extension or Y-harness handy,

you may want to attach it temporarily to the flap servo

lead as it will make it easier to connect the flap servo

to the receiver while the servo installation is being

finalized.

Step 19

Use a pushrod keeper to connect the flap pushrod to the flap

servo horn.

Step 20

If you have a three-position flap switch, it is recommended

to set the endpoint to 0%. This will make installing the flap

much easier.

Step 21

Place the flap servo into position and check the

measurement for the mid flap setting. You may need to

adjust the length of the pushrod to achieve the correct

measurement.

Note

: If you have a two-position switch, you will not

need to make this measurement. You will only be

setting the ‘up’ and “down” flap positions.

Important

: Do not operate the flap using the radio

system at this time. If the throws are too great, it could

damage the servo if the servo moves more than the flap

can. Setting the throws to 0% at your radio as a starting

point is the best method for installing the flap servo. If

you have not set the throws to 0%, simply lift the flap

servo cover from the wing BEFORE operating the flap

servo from the radio system to make sure the servo

does not bind when operated.

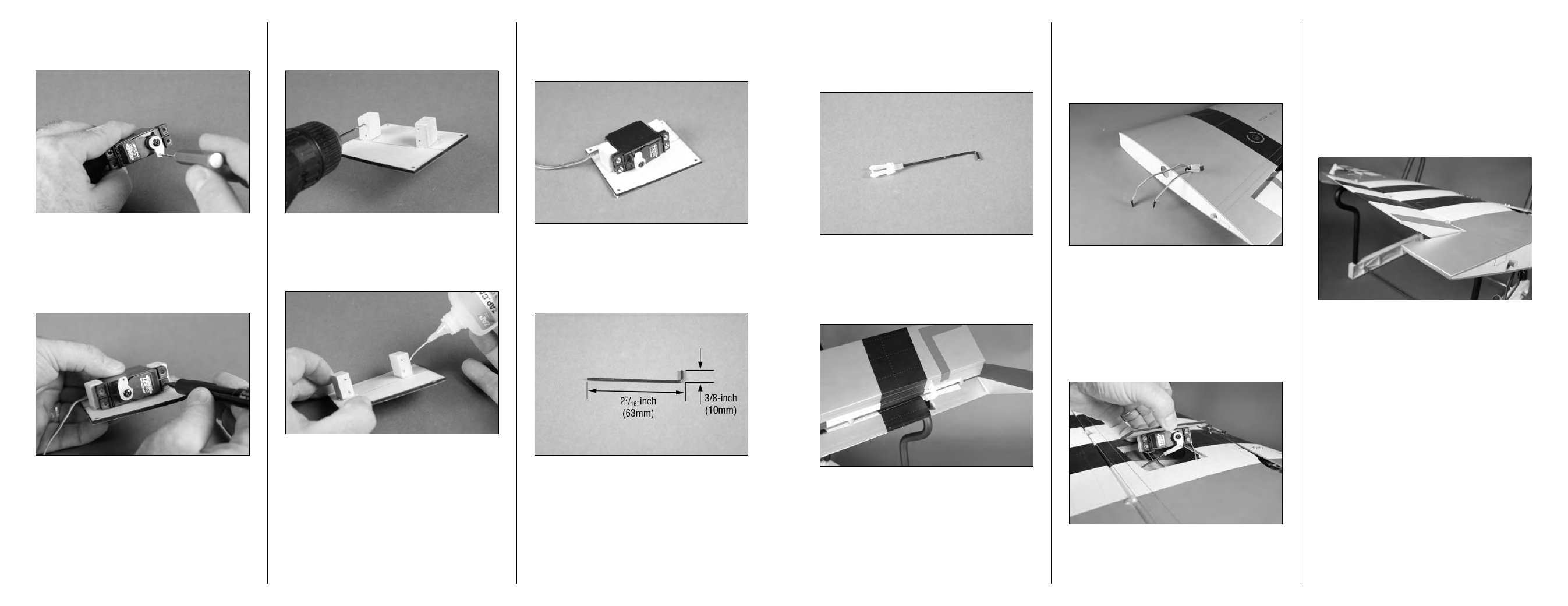

Step 10

Use a 5/64-inch (2mm) drill bit and pin drill to enlarge the

hole in the flap servo horn.

Step 11

Position the servo between the blocks. Leave a small gap

of 1/32-inch (1mm) between the servo cover and servo to

prevent vibrations from the airframe from being transferred

directly to the servo. Use a pencil to mark the blocks for the

four servo mounting screws.

Hint

: Place a 1/32-inch (.5mm) spacer between the

servo and the servo hatch cover before marking the

mounting holes.

Step 12

Remove the servo. Use a drill and 1/16-inch (1.5mm) drill bit

to drill the four holes for the servo mounting screws.

Step 13

Apply 2–3 drops of thin CA into each hole to harden the

surrounding wood. This provides a harder surface for the

screws making them more secure when installed.

Step 14

Use the screws provided with the servo to secure it to the

servo mounting blocks. Use a #1 Phillips screwdriver to

tighten the servo mounting screws.

Step 15

Prepare the flap pushrod by making a 90-degree bend that

is 2

7

/

16

-inch (63mm) from the threaded end of the pushrod.

Measure 3/8-inch (10mm) from the bend and use side

cutters to trim the pushrod wire.