Flap servo installation – Hangar 9 P-51D Blue Nose 60 ARF User Manual

Page 12

22

Hangar 9 P-51 Mustang 60 ARF Assembly Manual

23

Hangar 9 P-51 Mustang 60 ARF Assembly Manual

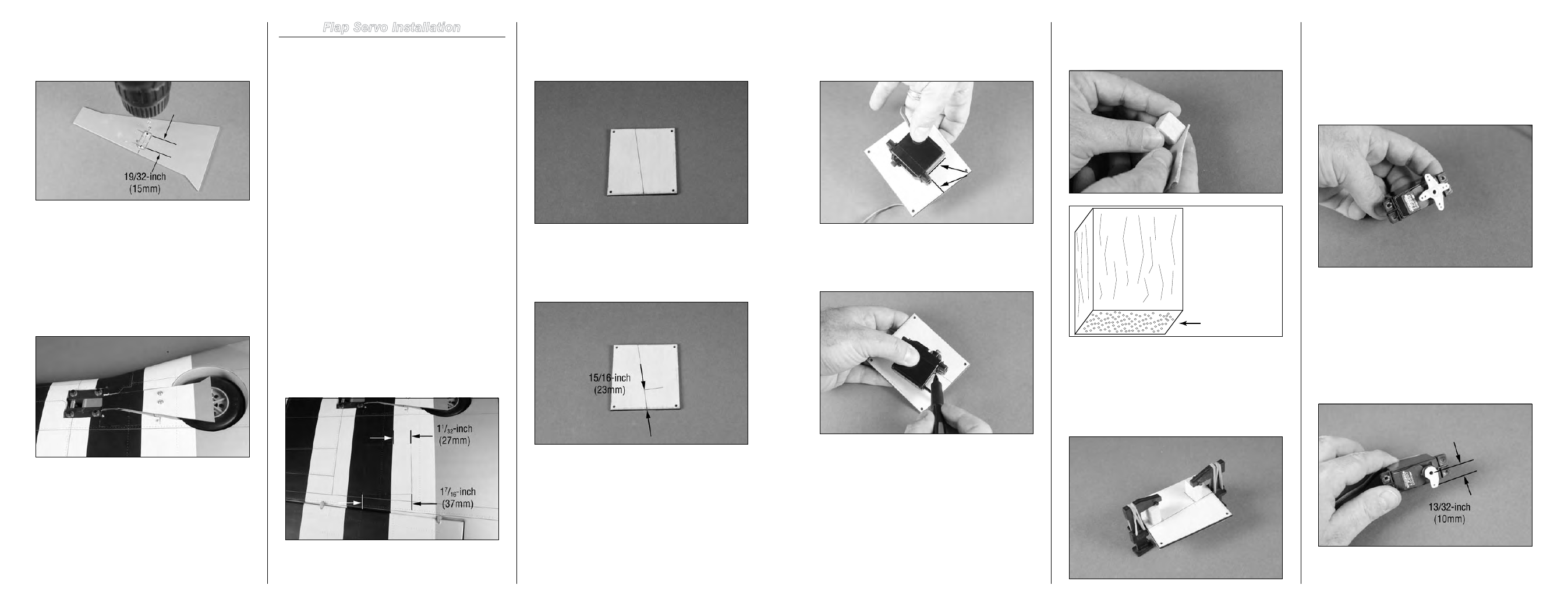

Step 4

Use a #1 Phillips screwdriver to remove the servo horn from

the servo. Position the servo on the cover. Use the lines for

aligning the servo on the cover.

Step 5

Use a pencil to mark the position for the second servo

mounting block on the servo cover.

Hint

: Use a 1/32-inch (.5mm) spacer between the

servo and flap servo cover before marking for the servo

mounting screws to set the correct spacing.

Step 6

Use medium grit sandpaper to scuff the ends of two servo

mounting blocks as shown.

Sand this end

Step 7

Mix a small amount of 30-minute epoxy. Apply the epoxy

to the end of the blocks that were sanded in the previous

step. Position the blocks on the servo cover using the marks

made previously. Use small clamps to hold the blocks tightly

against the servo cover until the epoxy fully cures.

Step 8

Use the radio system to center the flap servo. If your radio

uses a three-position switch, set the switch in the center

position. If you have a two-position switch, setting the

throws to 0% for both positions will also center the flap

servo. Install a servo horn on the flap servo that has a hole

13/32-inch (10mm) from the center of the horn. Install the

horn on the flap servo as shown.

Hint

: Most servos have an odd number of splines. If

the horn is not aligned correctly as shown, you can

rotate it 180 degrees to bring it into alignment.

Step 9

Use side cutters to remove any arms that will not be used

from the servo horn. Trim the horn down leaving only the

hole that was 13/32-inch (10mm) from the center of the

horn.

Step 29

Use a drill and 1/8-inch (3mm) drill bit to drill two holes

through the gear door as shown. Use care not to tear the

covering when drilling through the gear door.

Hint

: Placing the gear door on a piece of wood while

drilling will minimize any possibility of damaging the

covering.

Step 30

With the gear in the “up” position, attach the gear door

to the gear door mount using two 3mm x 8mm machine

screws and two 3mm washers. Use a #2 Phillips screwdriver

and threadlock to install the screws.

Hint

: If the gear door does not align, loosen the screws

to reposition the gear door or loosen the setscrew on

the gear door mount to align the trim scheme. If that

does not work, the holes can be enlarged slightly to

make minor adjustment to the alignment.

Step 31

Repeat Steps 1 through 30 to install the retract mechanism

in the remaining wing panel.

Flap Servo Installation

Required Parts

Wing panel (right and left)

Servo mounting block (4)

2-inch (52mm) safety tubing

6-inch (152mm) threaded pushrod (2)

#2 x 3/8-inch sheet metal screw (8)

Servo (2)

Receiver

Transmitter

Receiver battery

Pushrod keeper (2)

Clevis (2)

Tools and Adhesives

30-minute epoxy

Sandpaper

Mixing stick

Pencil

Clamp (2)

Medium grit sandpaper

Ruler

Phillips screwdriver: #1

Side cutter

Thin CA

Hobby knife with #11 blade Pliers

T-pin

Drill

Drill bit: 1/16-inch (1.5mm), 5/64-inch (2mm)

Rotary tool and cutoff wheel

Step 1

Place the flap servo cover in position on the wing. Use a

ruler and pencil to make a mark that is 1

1

/

32

-inch (27mm) in

from the edge of the cover near the retract. Make a second

mark that is 1

7

/

16

-inch (37mm) in from the edge of the cover

near the root of the wing.

Step 2

Remove the cover and transfer the marks to the bottom side

of the cover. Draw a line that connects the two marks. This

will be used in aligning the position of the servo.

Step 3

Measure 15/16-inch (23mm) from the edge that was

toward the trailing edge of the cover. Draw a line that is

perpendicular to the first as shown.