Elevator/stabilizer installation – Hangar 9 P-51D Blue Nose 60 ARF User Manual

Page 18

34

Hangar 9 P-51 Mustang 60 ARF Assembly Manual

35

Hangar 9 P-51 Mustang 60 ARF Assembly Manual

Elevator/Stabilizer Installation

Required Parts

Fuselage

Stabilizer tube (short)

Stabilizer tube (long)

Clevis safety tubing

Clevis (2)

Transmitter

Wheel collar, 4mm (2)

Pushrod keeper

3mm x 3mm setscrew (2)

Servo with hardware

Stabilizer assembly (right and left)

#2 x 3/8-inch sheet metal screw (8)

Pushrod wire, 30

1

/

2

-inch (775mm) (2)

Tools and Adhesives

Hobby knife with #11 blade Felt-tipped pen

Rubbing alcohol

Paper towel

30-minute epoxy

Mixing cup

Mixing stick

Low-tack tape

Epoxy brush

Pin drill

Phillips screwdriver: #1, #2 Side cutters

Rotary tool with cutoff wheel Pliers

Drill bit: 1/16-inch (1.5mm), 5/64-inch (3mm)

Threadlock

Hex wrench: 1.5mm

Thin CA

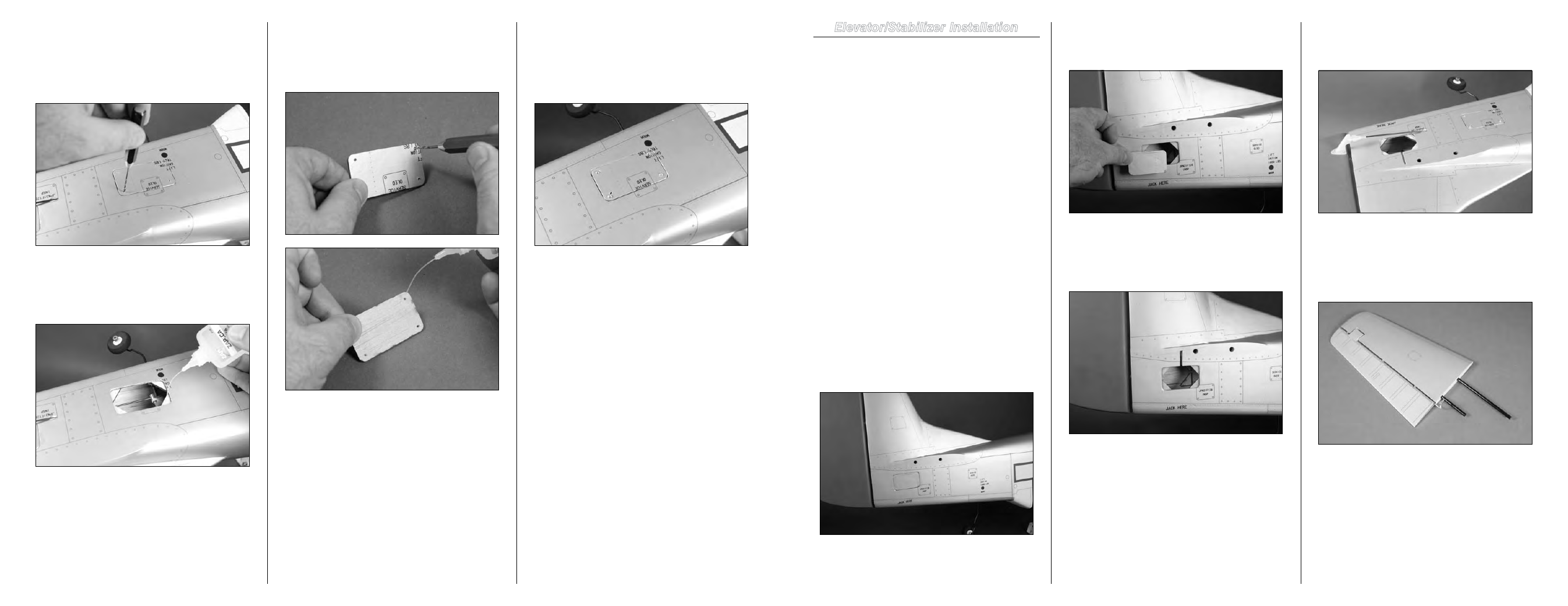

Step 1

Use a hobby knife and #11 blade to remove the covering for

the two stabilizer tubes in the fuselage.

Step 2

Remove the access cover from the side of the fuselage. Set

it aside for the time being.

Step 3

Use a hobby knife with a #11 blade to remove the covering

from the linkage slot above the access hole on the side of

fuselage.

Step 4

Repeat Steps 1 though 3 for the opposite side of the

fuselage.

Step 5

Slide the long and short stabilizer tubes into the stabilizer

half. Note the longer tube is in the hole toward the leading

edge of the stabilizer (front) and the shorter tube toward the

elevator (rear).

Step 36

Place the access cover back in place on the fuselage. Use

a pin drill and 1/16-inch (1.5mm) drill bit to drill four holes

through the cover and into the fuselage. Make sure to

position the holes so they are roughly 3/32-inch (2mm) from

the edges of the cover.

Step 37

Apply 2–3 drops of thin CA into each hole to harden the

surrounding wood. This provides a harder surface for the

screws making them more secure when installed.

Step 38

Use a 5/64-inch (2mm) drill bit to enlarge the holes in the

cover. Apply 2–3 drops of thin CA into each hole to harden

the surrounding wood. This will harden the wood and help it

hold up to the pressure of the screws over time.

Step 39

Secure the cover to the fuselage using four #2 x 3/8-inch

sheet metal screws. Use a #1 Phillips screwdriver to tighten

the four screws. The screws only need to be tight enough to

secure the cover: don’t tighten them too much and crush the

wood of the cover.