Receiver, rudder servo and tail wheel installation – Hangar 9 P-51D Blue Nose 60 ARF User Manual

Page 14

26

Hangar 9 P-51 Mustang 60 ARF Assembly Manual

27

Hangar 9 P-51 Mustang 60 ARF Assembly Manual

Receiver, Rudder Servo and Tail Wheel

Installation

Required Parts

Fuselage

Tail gear wire with wheel

Tail gear steering arm

Pushrod connector

1.5mm washer

C-clip

2.5mm wheel collar (2)

3mm setscrew (3)

Clevis

Clevis safety tubing

Servo

Receiver

Transmitter

Receiver battery

Pushrod keeper

Switch harness

Control horn with backplate

2mm x 32mm machine screw (3)

#2 x 3/8-inch sheet metal screw (4)

Pushrod wire, 30

1

/

2

-inch (775mm)

Tools and Adhesives

Hook and loop strap

Pin drill

Felt-tipped pen

1/4-inch (6mm) foam

Pliers

Side cutter

Rubbing alcohol

Paper towel

Pencil

Thin CA

Phillips screwdriver: #1

Threadlock

Rotary tool with cutoff wheel T-pin

Hobby knife with #11 blade

Hex wrench: 1.5mm (included)

6-inch (152mm) servo extension (4)

Drill bit: 1/16-inch (1.5mm), 5/64-inch (2mm)

Extensions for 7-Channel Receiver Installation

3-inch (76mm) servo extension (2)

Y-harness (2)

Extensions for 9-Channel Receiver Installation

3-inch (76mm) servo extension (6)

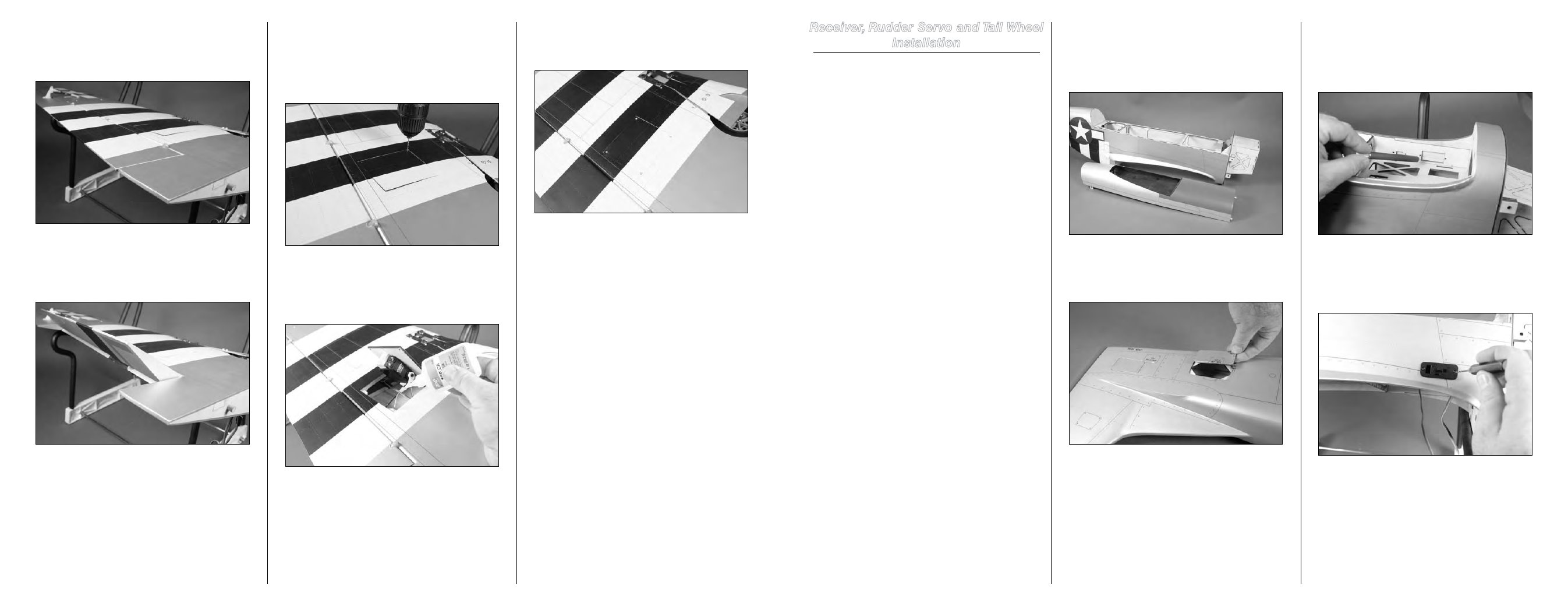

Step 1

Remove the fuselage hatch from the fuselage by lifting it

up at the rear to release the magnets. Slide the hatch to the

rear of the fuselage to release the pegs at the front and set it

aside.

Step 2

Remove the access cover for the tail wheel from the

fuselage. Set it aside with the fuselage hatch.

Note

: Steps 3 through 6 are for mounting the switch

harness and receiver battery for glow-powered models.

If you are preparing your model for electric power, you

can skip to Step 7 and mount the receiver.

Step 3

Use a hobby knife to remove the balsa from the side of the

fuselage for mounting your particular switch. The plywood

will have the correct cutout for the most common switches

available.

Step 4

Place your switch harness into the appropriate hole. Use a

pin drill and 1/16-inch (1.5mm) drill bit to drill the two holes

necessary to mount the switch to the fuselage.

Step 22

After setting the throws to 0%, move the switch on the radio

to the “up” position. Adjust the throw at the radio until the

flap is aligned with the trailing edge of the wing.

Step 23

Move the switch on the radio to the “down” position. Adjust

the throw at the radio until the flap is set at the measurement

listed under “Control Throws” for down flap.

Step 24

Use a T-pin to poke through the four holes in the covering in

the flap servo cover. Position the servo cover in the wing and

use a 1/16-inch (1.5mm) drill bit to drill the four holes for

the servo cover mounting holes. Use caution or you could

accidentally drill through the top of the wing.

Step 25

Apply 2–3 drops of thin CA into each hole to harden the

surrounding wood. This provides a harder surface for the

screws making them more secure when installed.

Step 26

Use a #1 Phillips screwdriver and four #2 x 3/8-inch sheet

metal screws to secure the servo cover to the wing.

Step 27

Repeat Steps 1 through 26 for the remaining flap servo

installation.