Engine installation: 2-stroke – Hangar 9 P-51D Blue Nose 60 ARF User Manual

Page 24

46

Hangar 9 P-51 Mustang 60 ARF Assembly Manual

47

Hangar 9 P-51 Mustang 60 ARF Assembly Manual

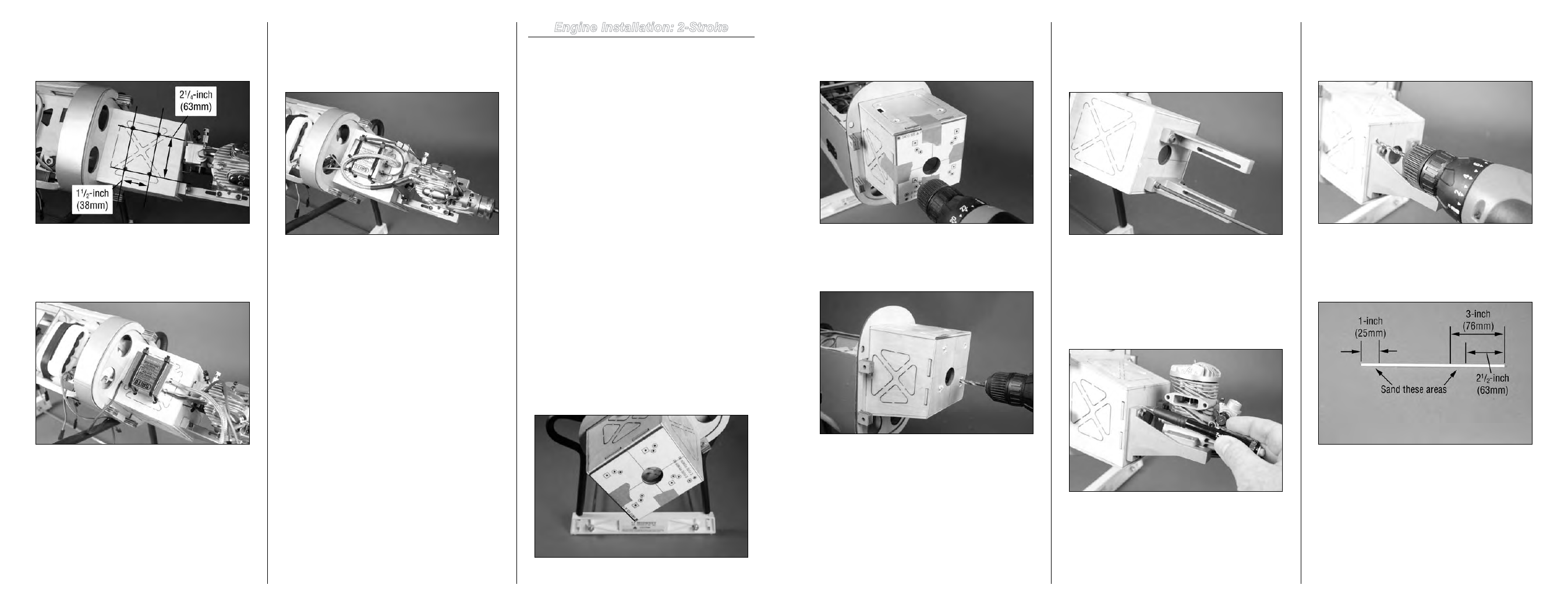

Step 2

Using a drill and 1/16-inch (1.5mm) drill bit, drill through the

template and through the firewall for the mount that fits your

particular engine.

Step 3

Remove the template from the firewall. Use a drill and 7/32-

inch (5.5mm) drill bit to enlarge the holes in the firewall.

Step 4

Use four 8-32 x 3/4-inch socket head bolts, four #8 washers

and four 8-32 blind nuts to secure the mount rails to the

firewall. Tighten the screws using a 9/64-inch hex wrench or

ball driver.

Important

: Make sure to use threadlock on all metal-

to-metal fasteners.

Step 5

Slide the engine into position between the engine mount

rails. Use a pencil to mark the location for the throttle

pushrod wire on the firewall.

Step 6

Remove the engine from the rails. Use a drill and 5/32-inch

(4mm) drill bit to drill a hole through the firewall for the

throttle pushrod tube.

Step 7

Use medium grit sandpaper to roughen an area that is 2

1

/

2

-

to 3 inches (63 to 76mm) from one end, as well as the last

1-inch (25mm) of the pushrod tube as shown.

Step 4

Use a drill and 1/4-inch (6mm) drill bit to drill four holes

in the bottom of the engine mounting box so the ignition

module can be secured to the fuselage.

Step 5

Place a piece of 1/4-inch (6mm) foam between the ignition

module and fuselage. Use two 12-inch (305mm) tie wraps to

secure the module to the fuselage.

Important

: Make sure not to install the tie wraps over

the throttle pushrod tube. This could cause the pushrod

to bind and cause the throttle servo to run the receiver

battery down prematurely.

Step 6

Make all the connections between the ignition battery, switch

and module according to the instructions provided with the

engine. Make sure to secure any loose wires so they do not

interfere with the operation of the engine or radio system.

Engine Installation: 2-Stroke

Required Parts

Fuselage assembly

Firewall template

8-32 blind nut (4)

Engine mount rail (2)

#8 washer (8)

Clevis

Safety tubing

Plywood pushrod support

Throttle servo with hardware 90-degree keeper

8-32 lock nut (4)

8-32 x 3/4-inch socket head bolt (4)

8-32 x 1

1

/

4

-inch socket head bolt (4)

Pushrod tube, 8

1

/

8

-inch (206mm)

Pushrod wire, 13

1

/

4

-inch (335mm)

Tools and Adhesives

Low-tack tape

Drill

Side cutters

Felt-tipped pen

Hobby knife with #11 blade Medium grit sandpaper

Phillips screwdriver: #1, #2 Medium CA

Pencil

Thin CA

Hex wrench or ball driver: 9/64-inch

Nut driver or socket: 11/32-inch

Drill bit: 1/16-inch (1.5mm),5/64-inch (2mm),

5/32-inch (4mm), 7/32-inch (5.5mm)

Step 1

Locate the firewall template. Use low-tack tape to secure it

to the engine box. A paper copy of the engine template is

located on Page 71 of this manual.