Hangar 9 P-51D Blue Nose 60 ARF User Manual

Page 20

38

Hangar 9 P-51 Mustang 60 ARF Assembly Manual

39

Hangar 9 P-51 Mustang 60 ARF Assembly Manual

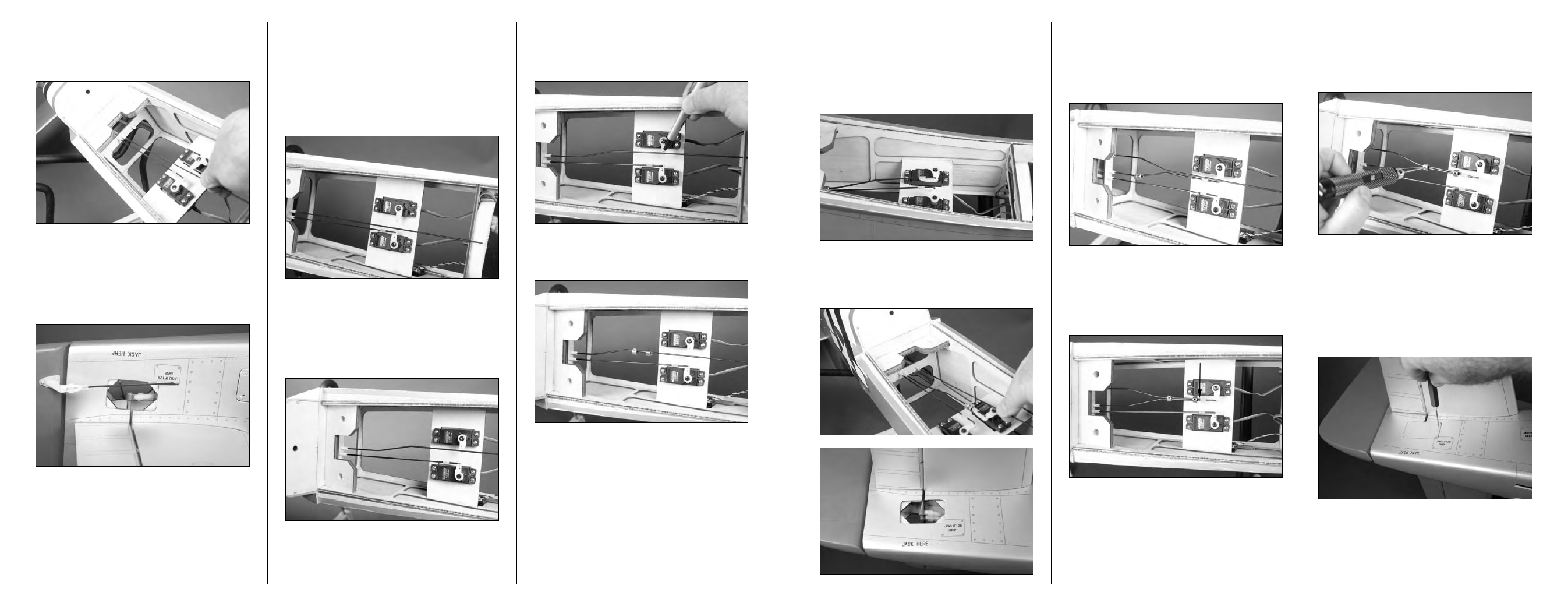

Step 22

Use pliers to bend the pushrod wire 90 degrees at the mark

made in the previous step. Trim the wire 3/8-inch (10mm)

above the bend using side cutters or a rotary tool. Insert the

wire into the hole in the servo arm. Slide the pushrod keeper

onto the wire, then rotate it and snap it on the wire to secure

the pushrod wire to the servo horn.

Step 23

Repeat Steps 16 and 17 to install the remaining 30

1

/

2

-inch

(775mm) pushrod wire.

Step 24

You will need to make two slight bends in the elevator

pushrod to align it with the first elevator pushrod wire

as shown. Make sure the bend is at least 1-inch (25mm)

forward of the pushrod tube so the bend does not bind in the

tube when operating the elevator.

Step 25

Use a rotary tool and cut off wheel or side cutters to trim the

pushrod wire so it almost touches the pushrod keeper. Slide

the wheel collars forward. Slide the bent pushrod wire into

the wheel collars.

Step 26

Use two 3mm x 3mm setscrews and a 1.5mm hex wrench to

secure the collars that link the two pushrods together. Make

absolute sure to use threadlock on these screws so they

don’t vibrate loose.

Step 27

Place the access cover back in place on the fuselage. Check

to make sure the trim scheme matches and that you are

not installing the cover on the wrong side of the aircraft.

Use a pin drill and 1/16-inch (1.5mm) drill bit to drill four

holes through the cover and into the fuselage. Make sure to

position the holes so they are roughly 3/32-inch (2mm) from

the edges of the cover.

Step 16

Slide one of the 30

1

/

2

-inch (775mm) pushrods, threaded end

first, into the elevator pushrod tube closest to the center line

of the fuselage inside of the fuselage.

Step 17

Cut a 1/4-inch (6mm) piece from the clevis safety tubing

and slide it over the clevis. Thread the clevis 10 turns on the

pushrod wire. Connect the clevis to the elevator control horn.

Slide the tubing over the clevis so it will not accidentally

open in flight.

Step 18

Use the radio system to center the servo for the elevator.

Remove the original arm from the elevator servo and install

a 180-degree arm so it is perpendicular to the center line of

the servo. You will be connecting the linkage to a hole that

is 9/16-inch (14mm) from the center of the servo horn, so

make sure your servo horn meets these requirements. Use

side cutters to remove any unused arms from the servo horn

that may interfere with the operation of the servo.

Step 19

You will need to make two slight bends in one elevator

pushrod to align it with the elevator servo horn as shown.

Make sure the bend is at least 1-inch (25mm) forward of the

pushrod tube so the bend does not bind in the tube when

operating the elevator.

Step 20

With the radio system on and the elevator centered, use a

felt-tipped pen to mark the pushrod wire where it crosses the

hole of the servo horn previously enlarged.

Step 21

Slide two 4mm wheel collars on the pushrod wire.