Engine installation: 4-stroke – Hangar 9 P-51D Blue Nose 60 ARF User Manual

Page 21

40

Hangar 9 P-51 Mustang 60 ARF Assembly Manual

41

Hangar 9 P-51 Mustang 60 ARF Assembly Manual

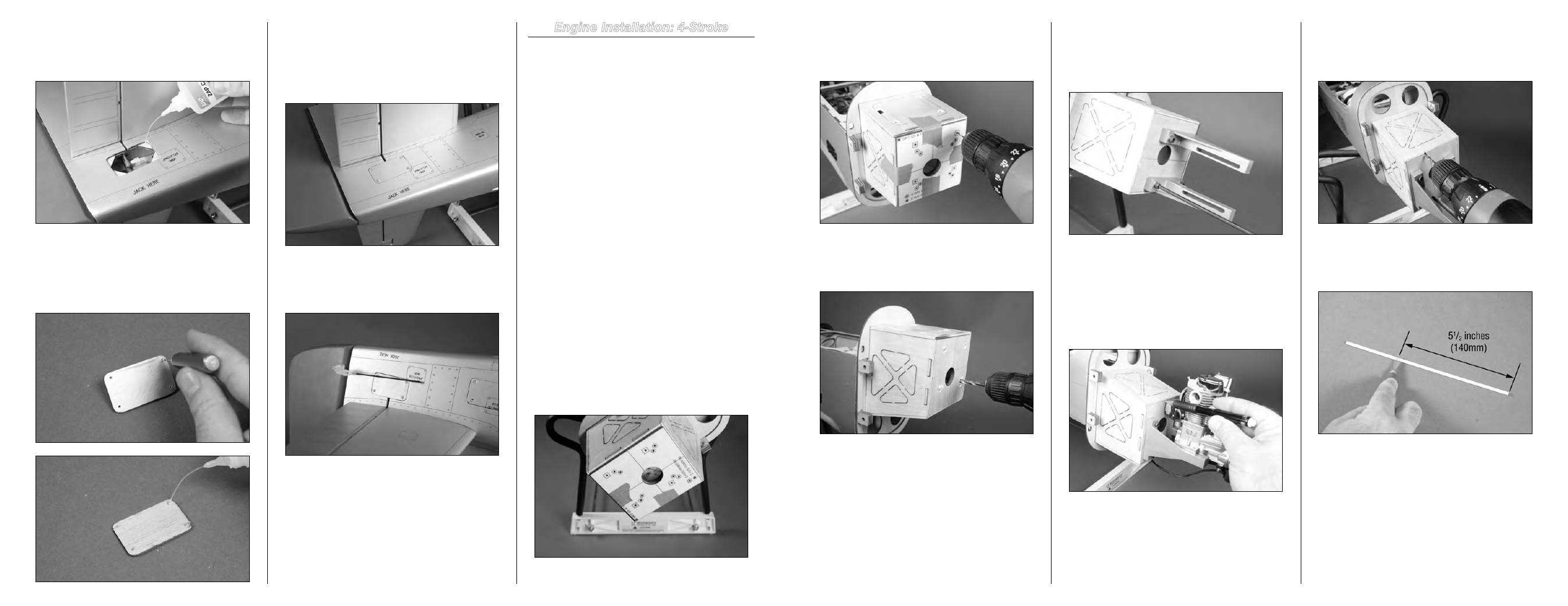

Step 2

Using a drill and 1/16-inch (1.5mm) drill bit, drill through the

template and through the firewall for the mount that fits your

particular engine.

Step 3

Remove the template from the firewall. Use a drill and 7/32-

inch (5.5mm) drill bit to enlarge the holes in the firewall.

Step 4

Use four 8-32 x 3/4-inch socket head bolts, four #8 washers

and four 8-32 blind nuts to secure the mount rails to the

firewall. Tighten the screws using a 9/64-inch hex wrench or

ball driver.

Important

: Make sure to use threadlock on all metal-

to-metal fasteners.

Step 5

Slide the engine into position between the engine mount

rails. Use a pencil to mark the location for the throttle

pushrod wire on the firewall.

Note

: If you are using a regular four-stroke, make

sure the carburetor arm is facing the same direction as

shown in the photo above.

Step 6

Remove the engine from the rails. Use a drill and 5/32-inch

(4mm) drill bit to drill a hole through the firewall for the

throttle pushrod tube.

Step 7

Use a hobby knife with a #11 blade to cut the throttle

pushrod to a length of 5

1

/

2

inches (140mm).

Step 28

Apply 2–3 drops of thin CA into each hole to harden the

surrounding wood. This provides a harder surface for the

screws making them more secure when installed.

Step 29

Use a 5/64-inch (2mm) drill bit to enlarge the holes in the

cover. Apply 2–3 drops of thin CA into each hole to harden

the surrounding wood. This will harden the wood and help it

hold up to the pressure of the screws over time.

Step 30

Secure the cover to the fuselage using four #2 x 3/8-inch

sheet metal screws. Use a #1 Phillips screwdriver to tighten

the four screws. The screws only need to be tight enough to

secure the cover; don’t tighten them too much and crush the

wood of the cover.

Step 31

Repeat Steps 27 through 30 to install the remaining elevator

access cover.

Engine Installation: 4-Stroke

Required Parts

Fuselage assembly

Firewall template

8-32 blind nut (4)

Engine mount rail (2)

#8 washer (8)

Clevis

Safety tubing

Plywood pushrod support

Throttle servo with hardware 8-32 lock nut (4)

8-32 x 3/4-inch socket head bolt (4)

8-32 x 1

1

/

4

-inch socket head bolt (4)

Pushrod tube, 8

1

/

8

-inch (206mm)

Pushrod wire, 13

1

/

4

-inch (335mm)

Tools and Adhesives

Low-tack tape

Drill

Side cutters

Felt-tipped pen

Hobby knife with #11 blade Medium grit sandpaper

Phillips screwdriver: #1, #2 Medium CA

Pencil

Thin CA

Pliers or Z-bend pliers

Hex wrench or ball driver: 9/64-inch

Nut driver or socket: 11/32-inch

Drill bit: 1/16-inch (1.5mm), 5/32-inch (4mm),

7/32-inch (5.5mm)

Step 1

Locate the firewall template. Use low-tack tape to secure it

to the engine box. A paper copy of the engine template is

located on Page 71 of this manual.