Hangar 9 P-51D Blue Nose 60 ARF User Manual

Page 17

32

Hangar 9 P-51 Mustang 60 ARF Assembly Manual

33

Hangar 9 P-51 Mustang 60 ARF Assembly Manual

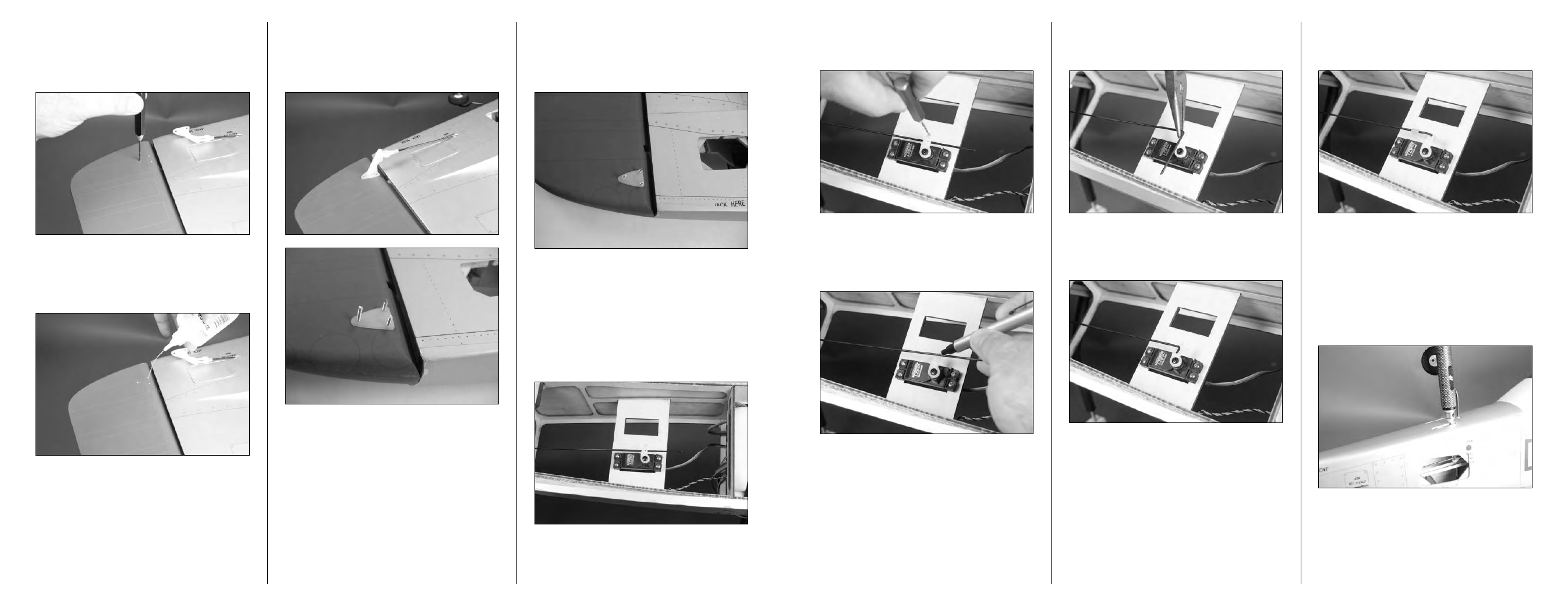

Step 30

Use a 5/64-inch (2mm) drill and pin drill to enlarge the hole

that is 9/16-inch (15mm) from the center of the servo arm.

Step 31

Make sure the rudder and rudder servo are centered. Use a

felt-tipped pen to mark the pushrod where it crosses the hole

in the servo arm enlarged in the previous step.

Step 32

Use pliers to bend the pushrod wire 90-degrees at the mark

made in the previous step.

Step 33

Use side cutters to trim the pushrod wire so only 3/8-inch

(10mm) of the wire remains beyond the bend.

Step 34

Use a pushrod keeper to secure the pushrod wire to the

servo horn.

Step 35

It is now time to secure the connector at the tail gear wire

to the pushrod. You will need to deflect the rudder slightly

so the setscrew can be accessed. Use a 1.5mm hex wrench

to tighten the setscrew that secures the connector to the

pushrod wire. Make sure that when the rudder is centered,

the tail wheel is centered as well. It may take a try or two to

get it correct. You will want to make sure to use threadlock

on this setscrew as accessing in the future will be difficult.

Hint: Use a file to make a flat spot on the pushrod wire

for the setscrew. This will make the connection between

the wire and setscrew more secure and less likely to

slip.

Step 25

Use a pin drill and 5/64-inch (2mm) drill bit to drill the three

holes through the rudder to mount the control horn. Use

care to drill the holes parallel in the rudder so the backplate

can be installed on the opposite side of the rudder.

Step 26

Apply 2–3 drops of thin CA into each hole to harden the

surrounding wood. This provides a harder surface for the

screws making them more secure when installed.

Step 27

Once the CA has cured, you can attach the control horn to

the rudder using three 2mm x 32mm machine screws and

the control horn backplate. Use a #1 Phillips screwdriver to

tighten the screws.

Step 28

Use side cutters to trim the length of the screws down. Use

a flat file to remove any sharp edges from the screws so they

don’t accidentally damage anything during the transport of

your aircraft.

Step 29

Use the radio system to center the servo for the rudder.

Remove the original arm from the rudder servo and install

a 180-degree arm so it is perpendicular to the center line of

the servo. You will be connecting the linkage to a hole that

is 9/16-inch (14mm) from the center of the servo horn, so

make sure your servo horn meets these requirements. Use

side cutters to remove any unused arms from the servo horn

that may interfere with the operation of the servo.