Hangar 9 P-51D Blue Nose 60 ARF User Manual

Page 27

52

Hangar 9 P-51 Mustang 60 ARF Assembly Manual

53

Hangar 9 P-51 Mustang 60 ARF Assembly Manual

Step 7

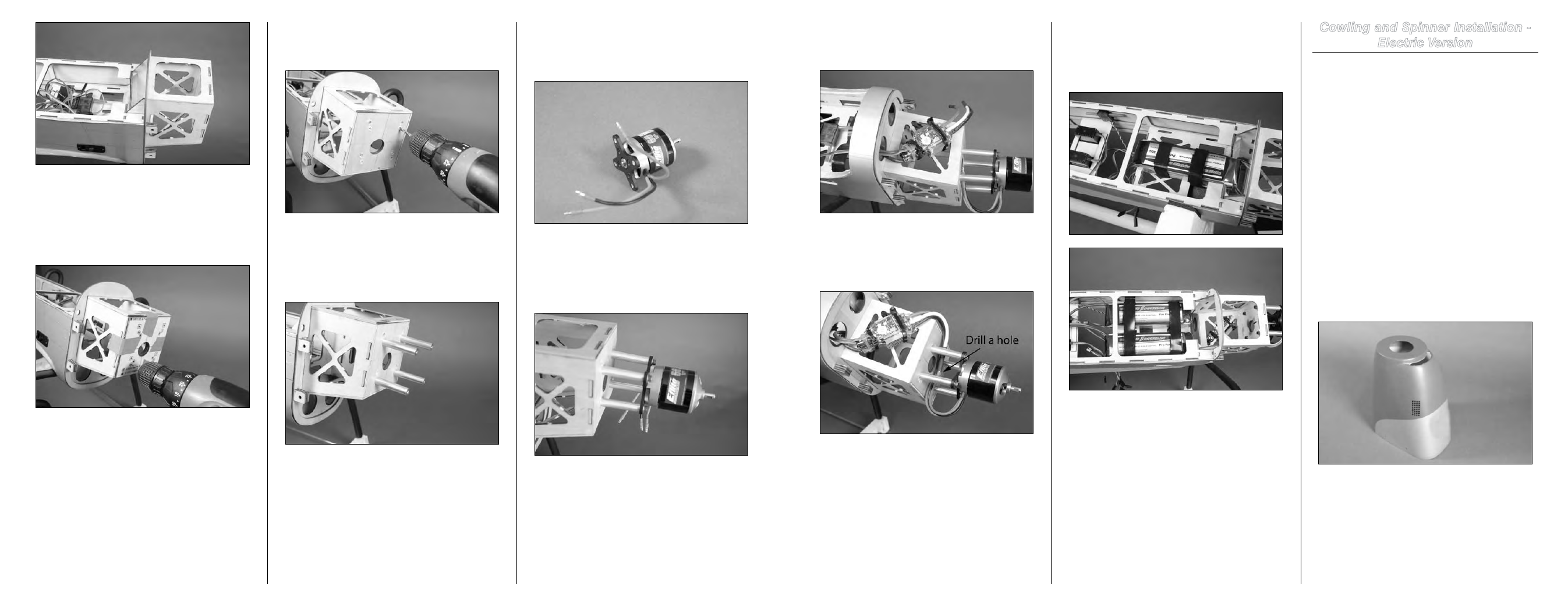

Secure the electronic speed control to the bottom of the

motor box using two-sided tape and tie wraps.

Step 8

Connect the leads between the speed control and motor. Use

tie wraps to secure the wiring so it will not get entangled in

the moving parts of the motor.

Hint

: Drill a 5/32-inch (4mm) hole through the firewall

so a tie wrap can be used to secure the wiring to the

firewall as shown.

Step 9

Plug the lead from the speed control into the throttle channel

of the receiver at this time.

Step 10

The batteries are mounted in the fuselage from the top side.

Use hook and loop straps to secure them in the fuselage.

It may be necessary to use hook and loop tape to keep the

batteries from sliding on the battery tray in the fuselage.

Note

: The second photo shows the dual battery

configuration for the Power 90.

Step 11

At this time check the operation of the motor using the radio

system. It should rotate counterclockwise when viewed

from the front of the fuselage. If it does not, refer to the

instructions included with the speed control to correct the

direction of rotation.

Cowling and Spinner Installation -

Electric Version

Required Parts

Fuselage assembly

Cowling

Spinner assembly

Propeller adapter

Propeller

Propeller nut

Spinner backplate spacer

3mm x 15mm socket head machine screw (4)

Tools and Adhesives

Rotary tool with sanding drum

Hobby knife with #11 blade

Hobby scissors

Box or open end wrench: 12mm

Hex wrench or ball driver: 2.5mm, 5/32-inch

Step 1

Carefully cut the opening in the front of the cowling to allow

cooling air to pass through the cowling. Use a rotary tool

with a sanding drum to clean up any rough edges left from

the hobby scissors.

Note

: Both motor options (Power 60 and Power 90)

have been tested and only require the opening in the

front of the cowling to allow cooling air to pass into the

fuselage.

Step 2

Locate the firewall template. Use low-tack tape to secure it

to the engine box. Use a drill and 1/16-inch (1.5mm) drill

bit, drill through the template and through the firewall for the

mount that fits your particular motor. A paper copy of the

engine template is located on Page 71 of this manual.

Step 3

Remove the template from the firewall. Use a drill and 5/32-

inch (4mm) drill bit to enlarge the holes in the firewall.

Step 4

Use four 8-32 x 3/4-inch socket head bolts and four #8

washers to secure the aluminum motor standoffs to the

firewall. Use a 9/64-inch hex wrench or ball driver to tighten

the bolts.

Important

: Make sure to use threadlock on all metal-

to-metal fasteners to prevent them from vibrating loose.

Step 5

Use a 2.5mm hex wrench or ball driver to attach the

X-mount to the motor using the screws provided with the

motor. Make sure to use threadlock on these screws as well.

Step 6

Use four 8-32 x 3/4-inch socket head bolts and four #8

washers to secure the motor to the aluminum standoffs. Use

threadlock on the screws before tightening them with a 9/64-

inch hex wrench or ball driver.