Cannon Instrument CMRV-5000 User Manual

Page 34

28

CANNON

®

Mini-Rotary Viscometer

CMRV-5000 Instruction & Operation Manual

Version 1.0b—August, 2011; CANNON

®

Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

CAUTION!

Exposure to acetone liquid or acetone vapor may damage the cover.

2. Ensure that the CMRV instrument power switch is on.

NOTE

The CMRV cleaning procedure may be initiated from a "cold" CMRV;

however, a calibration or profile should not be initiated until the instrument

has completed a warmup period of approximately 45 minutes. If the

warm-up period is less than 45 minutes, the instrument may not control

temperature within acceptable tolerance parameters.

3. Assemble the necessary cleaning supplies:

oil solvent

acetone (optional during low humidity)

suitable solvent-resistant container for placing/cleaning rotors

vacuum w/trap for solvent and oil

flexible tube, about 150 mm long and 3-5 mm in diameter, connected

to the vacuum trap

two plastic squeeze bottles, each with an extension long enough to be

able to direct oil solvent and acetone directly into the cup of the

viscometer cells

4. Start the VISCPRO

®

software.

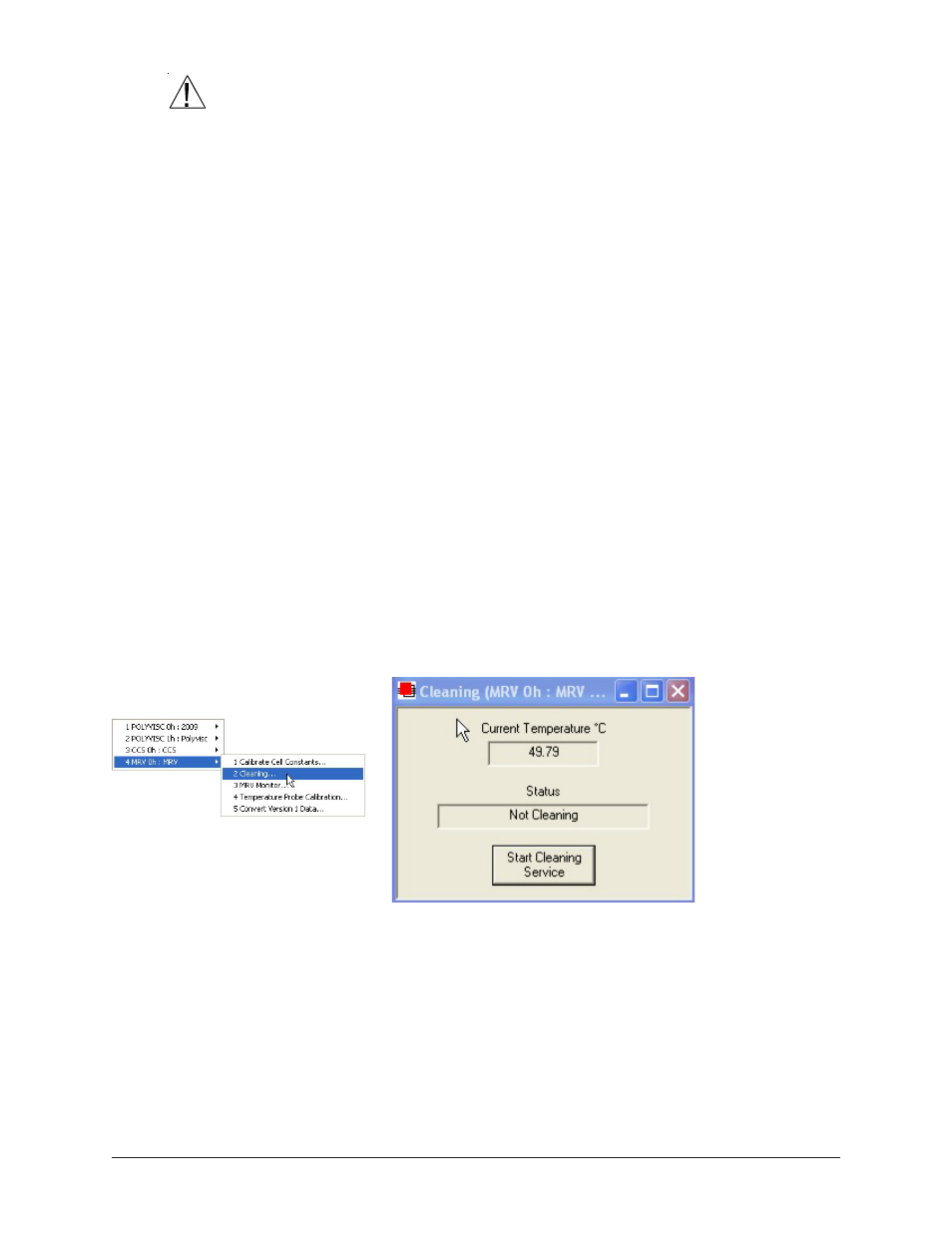

5. Click Service/MRV and select the Cleaning ... option to open the

Cleaning Service window. The window displays the current CMRV

block temperature for the selected instrument, as measured by the

temperature probe. The window also indicates the current instrument

status.

The Cleaning Service window

6. Click Start Cleaning Service. to initiate the cleaning cycle. The

instrument will be heated to 50°C for convenient cleaning.

7. Remove the threads from the rotors and set the threads aside.

NOTE

CANNON

®

recommends hanging the threads on individual hooks during

cleaning. Hanging a paper clip on each loop reduces the chance of curling.

8. Wait for the CMRV-5000 to reach the cleaning temperature.