Brookfield DV-I Prime User Manual

Page 56

Brookfield Engineering Laboratories, Inc.

Page 56

Manual No. M/07-022-D0613

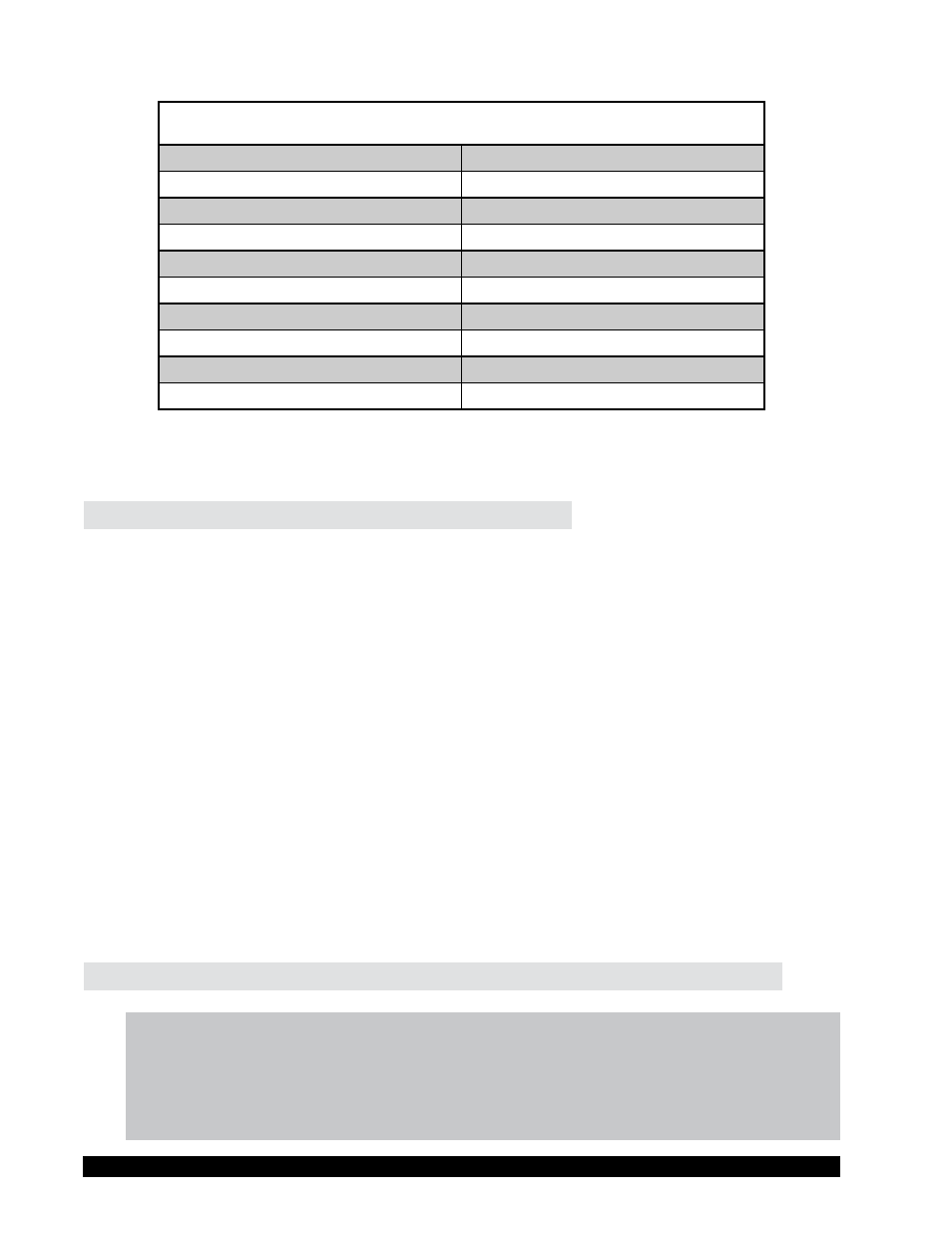

MINERAL OIL VISCOSITY STANDARD FLUIDS

BEL Part No.

Viscosity (cP) 25ºC

B29

29

B200

200

B600

600

B1060

1,060

B2000

2,000

B10200

10,200

B21000

21,000

B730000

73,000

B200000

200,000

B360000

360,000

Table E-2

Brookfield Viscosity Standard Fluid - General Information

We recommend that Brookfield Viscosity Standard Fluids be replaced on an annual basis, one year

from date of initial use. These fluids are either pure silicone or mineral oil and are not subject

to change over time. However, exposure to outside contaminants through normal use requires

replacement on an annual basis. Contamination may occur by the introduction of solvent, standard

of different viscosity or other foreign material.

Viscosity Standard Fluids may be stored under normal laboratory conditions. Mineral oils should

be stored in the container in which they are supplied. Disposal should be in accordance with state,

local and federal regulations as specified on the material safety data sheet; MSDS information is

available upon request on our website to down load.

Brookfield Engineering Laboratories does not recertify Viscosity Standard Fluids. We will issue

duplicate copies of the Certificate of Calibration for any fluid within two years of the purchase date.

Brookfield Viscosity Standard Fluids are reusable provided they are not contaminated. Normal

practice for usage in a 600 mL beaker is to return the material from the beaker back into the

bottle. When using smaller volumes in accessories such as Small Sample Adapter, UL Adapter,

Thermosel or Spiral Adapter, the fluid is normally discarded.

Calibration Check Procedure for LV (#1-3) and RV,HA,HB (#1-6) Brookfield Spindles

NOTE:

The LV #4 (#64) and the RV, HA, HB #7 spindle have been omitted from this

procedure. Brookfield does not recommend the use of these spindles to perform

a calibration check on your instrument. Reasons pertain to the small amount of

spindle surface area that makes contact with the viscosity standard, the difficulty

of establishing the immersion mark precisely and the need for precise temperature

control at 25°C in the immediate vicinity of the spindle.