Brookfield DV-I Prime User Manual

Page 34

Brookfield Engineering Laboratories, Inc.

Page 34

Manual No. M/07-022-D0613

II.12.3 The Bingham Model

€

t =

€

t

o

+ hD (

€

t

= shear stress,

€

t

o

= yield stress, h = plastic viscosity, and D = shear rate)

What does it tell you?

The Bingham model indicates a product’s yield stress,

€

t

o

, which is the amount of shear stress

required to initiate flow. It also provides the plastic viscosity,

h

, which is the viscosity after a

product yields.

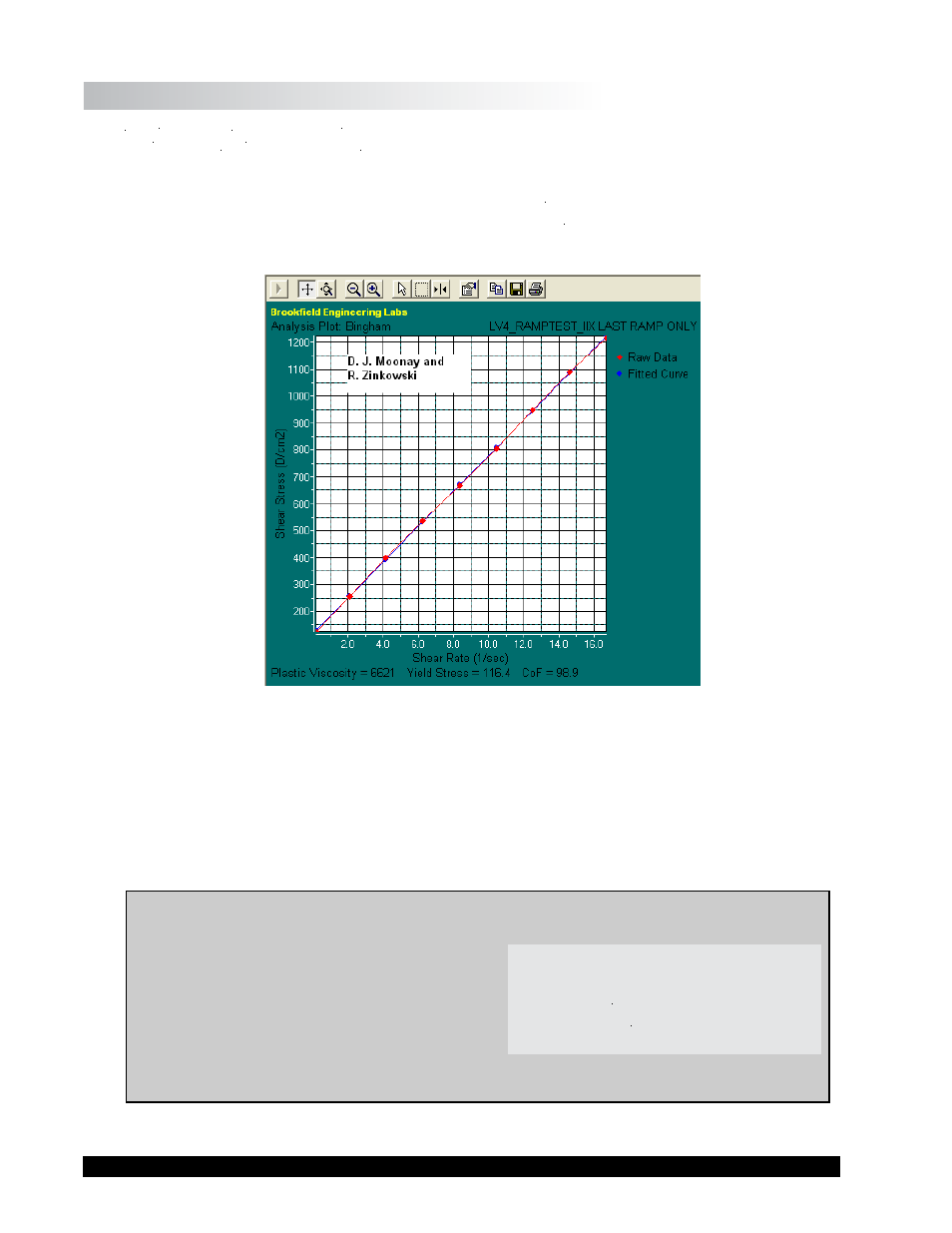

Figure II-45

When should you use it?

This model should be used with non-Newtonian materials that have a yield stress and then behave

in a Newtonian fashion once they begin to flow. As a result, the shear stress-shear rate plot forms

a straight line after yielding. (Products that have a yield stress only begin to flow after a certain

amount of shear stress is applied. They are also called “viscoplastic”. Their shear stress vs. shear

rate graphs intersect the y-axis at a point greater than 0.)

An Example of the Bingham Model at Work

A manufacturer of drilling fluid applies the

Bingham Model to ensure the quality of their

product. Results from a recent batch, shown

in Figure II-45, showed that the yield stress

and plastic viscosity were both below the

pass/fail criteria, which would cause the fluid

to insufficiently hold-up the cuttings. The

shipment was cancelled and the root-cause

of the problem was identified.

Drilling Fluid

Plastic Viscosity (

h

) = 6621 cP

Yield Stress (

€

t

o

) = 166.4 dynes/cm

2