B&C Technologies SA Series Industrial User Manual

Page 72

TROUBLE SHOOTING

7-12

5

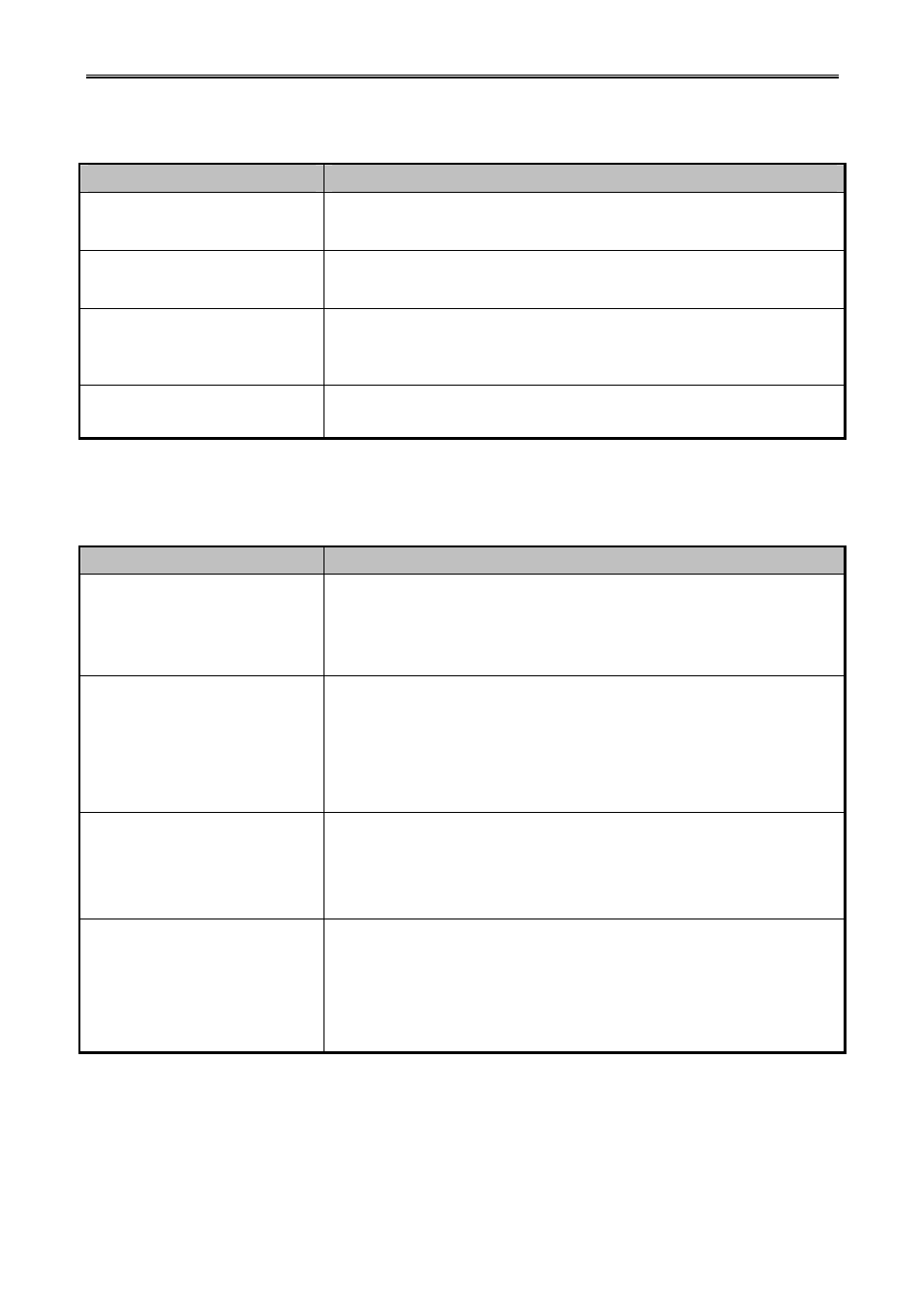

“OPL” Output phase loss protection

Problem

Output phase loss occurred.

Possible Causes

What to Check and Suggested Measures

1. Inverter output wires are

broken

Measure the output current.

→ Replace the output wires.

2. Wire for motor winding

are broken

Measure the output current.

→ Replace the

motor.

3. The terminal screws for

inverter output were not

tight enough.

Check if any terminal screws have become loose.

→ Tighten the terminal screws to the recommended torque.

4. A single – phase motor has

been connected

Single – phase motor cannot be used. Note that the FRENIC –

Mini only drives three-phase induction motors.

6.

“OH1” Overheat protection for heat sink

Problem

Temperature around heat sink rose.

Possible Causes

What to Check and Suggested Measures

1. Temperature around the

inverter exceeded that of

inverter specifications.

Measure the temperature around the inverter.

→ Lower the temperature around the inverter (e.g., ventilate the

enclosure well).

→ Lighten the load.

2. Accumulated running time

of the cooling fan

exceeded the standard

period for replacement, or

the cooling fan

malfunctioned

Check the accumulated running time (E52 = 2). Refer to “Reading

Maintenance Information”.

→ Replace the cooling fan.

Visually check that the cooling fan rotates normally.

→ Replace the cooling fan.

3. Air vent is blocked.

Check if there is sufficient clearance around the inverter.

→ Increase the

clearance.

Check if the heat sink is clogged.

→ Clean the heat sink.

4. Load was too heavy.

Measure the output current.

→ Lighten the load (e.g., lighten the load before the overload

protection occurs using the overload early warning (E34).

→ Decease the carrier frequency (F26).

→ Enable the overload protection control (H70).