B&C Technologies SA Series Industrial User Manual

Page 17

INSTALLATION PROCEDURES

3-5

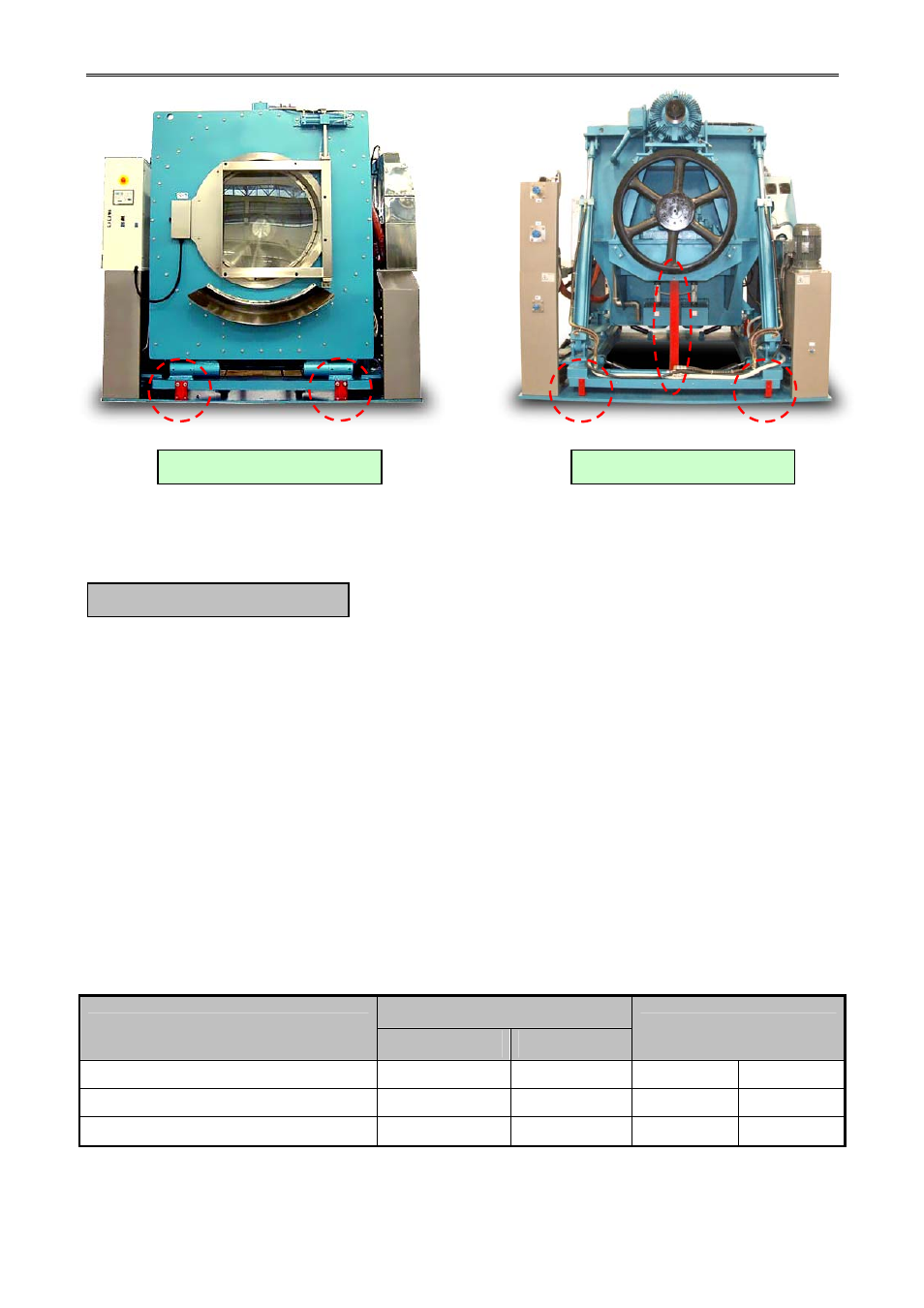

Figure.3-5 Location of transportation brackets inside the machine

A drain system of adequate capacity is essential to the machine performance. Ideally the

water should empty through a 4 inches vented pipe directly into a sump or floor drain.

A flexible connection must be made to a vented drain system to prevent an airlock or siphon

effect. If proper drain size is not available or practical, a surge tank is required. A surge tank in

conjunction with a sump pump should be used when gravity drainage is not possible, such as in

below – ground – level installations.

Before any deviation from specified installation procedures is attempted, the customer or

installer should contact the manufacturer. Increasing the drain hose length, installing elbows, or

causing bends will decrease drain flow rate and increase drain time, impairing machine

performance. If the drain arrangement is inadequate, the machine will not extract and will not

discharge water properly.

See table below for specific drain information.

Table.3-3 Drain Sizing

Units

Detail

Metric

US

SA Series

Drain connection Size

mm.

in

215

8 1/2

Drain flow capacity

liters / min

g.p.m.

-

-

Minimum drain it size

liters

gal

-

-

D. DRAIN CONNECTION

Front side the machine

Rear side the machine