B&C Technologies SA Series Industrial User Manual

Page 63

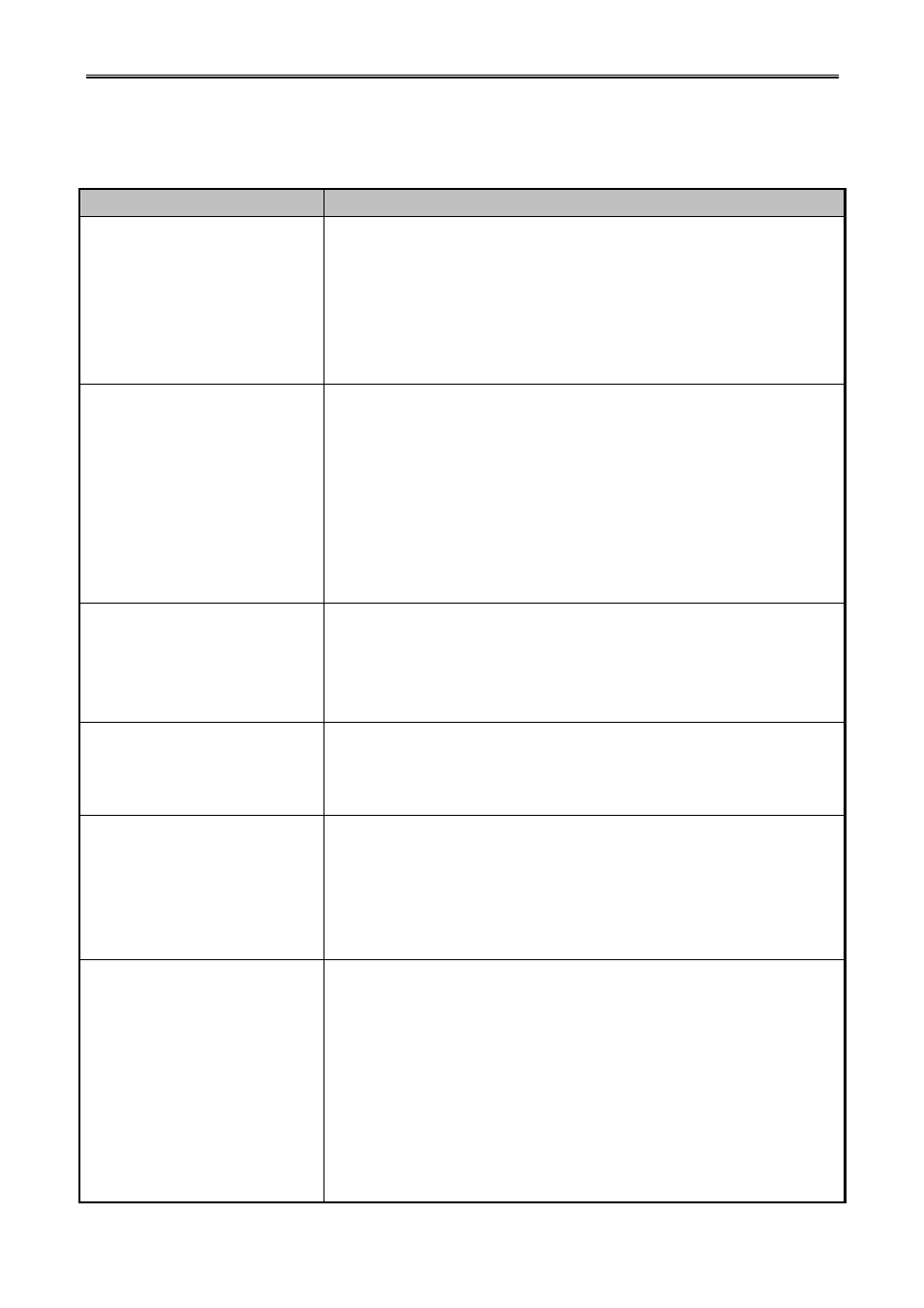

TROUBLE SHOOTING

7-3

If no alarm code appears on the LED monitor

Motor is running abnormally

1.

The motor does not rotate.

Possible Causes

What to Check and Suggested Measures

1. No power supplied to the

inverter.

Check the input voltage, output voltage and inter phase voltage

unbalance.

→ Turn on a molded case circuit breaker, an earth leakage circuit

breaker (with the exception of those exclusively designed for

protection from ground faults) or a magnetic contactor.

→ Check for voltage drop, phase loss, poor connections, or poor

contacts, and fix them if necessary.

2. No forward / reverse

operation command was

inputted, or both the

commands were inputted

simultaneously (external

signal operation).

Check the input status of the forward / reverse command with

Menu #4 “I/O checking” using the keypad.

→ Input a run command.

→ Set either the forward or reverse operation command to off if

both commands are being inputted.

→ Correct the assignment of commands (FWD) and (REV) to

function codes E98 and E99.

→ Connect the external circuit wires to control circuit terminals

(FWD) and (REV) correctly.

3. No indication of rotation

direction (keypad

operation).

Check the input status of the forward/reverse rotation direction

command with Menu #4 “I/O Checking” using the keypad.

→ Input the rotation direction (F02=0), or select the keypad

operation with which the rotation direction is fixed (F02=2 or

3)

4. The inverter could not

accept any run commands

from the keypad since it

was not in running mode.

Check which operation mode the inverter is in, using the keypad.

→ Shift the operation mode to Running mode.

5. A run command with

higher priority than the

one attempted was active

and the run command was

stopped.

While referring to the block diagram of the drive command

generator

*

check the higher priority run command with Menu #2

“Data checking” and Menu #4 “I/O checking” using the keypad.

*

Refer to the FRENIC – Mini User’s Manual (MEH446).

→ Correct any incorrect function code data settings (e.g., cancel

the higher priority run command).

6. The set frequency was set

to the same or lower than

the value of the starting or

stop frequency.

Check that a frequency command has been entered, with Menu #4

“I/O checking” using the keypad.

→ Set the value of the set frequency to the same of higher than

that of the starting or stop frequency (F23 or F25).

→ Reconsider the starting and stop frequencies (F23 and F25),

and if necessary, change them to lower values.

→ Inspect the frequency command devices, signal converters,

switches or relay contacts. Replace any ones that are faulty.

→ Connect the external circuit wires correctly to terminals (13),

(12), (11) and (C1).