Rice Lake Combination System - Precision Loads On-Board Weighing Systems User Manual

Page 43

Applications

39

11. Clamp the body angles to the subframe.

12. Remove the load cells for final welding. Final weld the body angles to the body subframe.

13. Once all welds have cooled, remount the load cells and Groove Lock hardware at each location. Use a

serviceable thread locker on all bolt threads used to bolt the Groove Lock plate assembly into the load cell,

and to bolt the load cells into the bearing plates. Torque all bolts to specification.

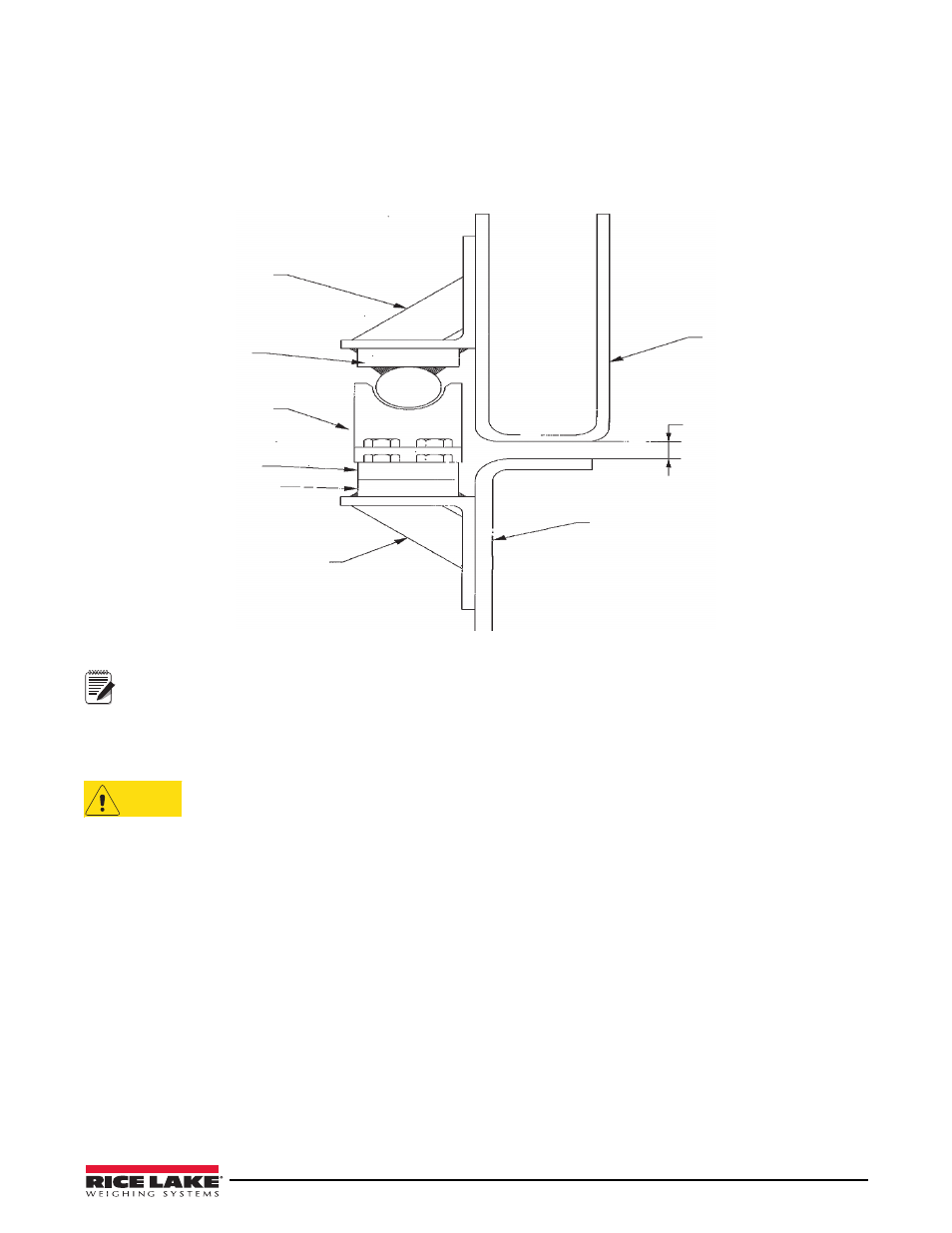

Figure 4-40. Groove Lock End View Showing PL9000-14 Load Cell

Rice Lake Weighing Systems recommends that load cell cables face inwards if possible, to provide better

protection. If the load cell output cables cannot face inwards, Rice Lake Weighing Systems recommends a

protective cover plate be welded to the chassis angle which provides protection to the cable and that split

loom, spiral wrap, split fuel line or other protection be fit to the load cell cables.

14. Remove all spacer blocks. Body subframe should rest on all load cells with Groove Lock hardware

centered on load cells. Raise and lower body to verify proper alignment and seating.

Installer must ensure that the hoist cylinder(s) do not retain pressure in the down (relaxed) position as that

will pull on the body rest load cells and affect the weight readings. All cylinder pressure must be relieved

when cylinders are relaxed and load cells are weighing load. Slow, creeping weight changes are a sign

that pressure may still be present in the lift cylinder(s). For example, in roll-off applications with dual acting lift cylinders,

the pressure on the down side of the cylinder must be relieved, typically by disengaging the PTO pump and lowering the

lever used for raising the hoist. A lever securing mechanism may be required to hold the lever in its down position if

pressure retention problems are experienced. Contact Rice Lake Weighing Systems if assistance is required.

Body Hoist Angle

6 x 4 x 1/2

Typical

Round Bar Plate

Groove Lock Bracket

Load Cell

Bearing Plate

Chassis Angle

6 x 4 x 1/2

Typical

Hoist Chassis

3/4” to 1”

Truck Chassis

Note

CAUTION