7 body rest mounts, 1 installation procedure, Installation procedure – Rice Lake Combination System - Precision Loads On-Board Weighing Systems User Manual

Page 41

Applications

37

Hoist Load Pin

1. Remove any existing collar when installing hoist load pin, and replace with the collar provided. Use the

load pin for locating and aligning pin and collar position, tack weld the collar in place, remove load pin and

final weld the collar per instructions.

2. Install bolt and locknut. Observe the "UP" notation stamped on the end of the hoist pin. Ensure the shear

grooves in each end of the pin overlap both sides of the mounting hardware (cheek plates and cylinder).

4.7

Body Rest Mounts

For installations of on-board systems on tipping bodies or hoist chassis which require live weighing, as opposed to

Lift-to-Weigh applications, body-rest load cell installations are required. Rice Lake Weighing Systems typically

supplies body rest kits in four or six point configurations, with two load pins typically installed at the rear hinge

pivots. The front two (or four) load cells used for body rest mounting utilizing Groove-Lock hardware is typically

the model PL9000-14.4 shear beam load cell.

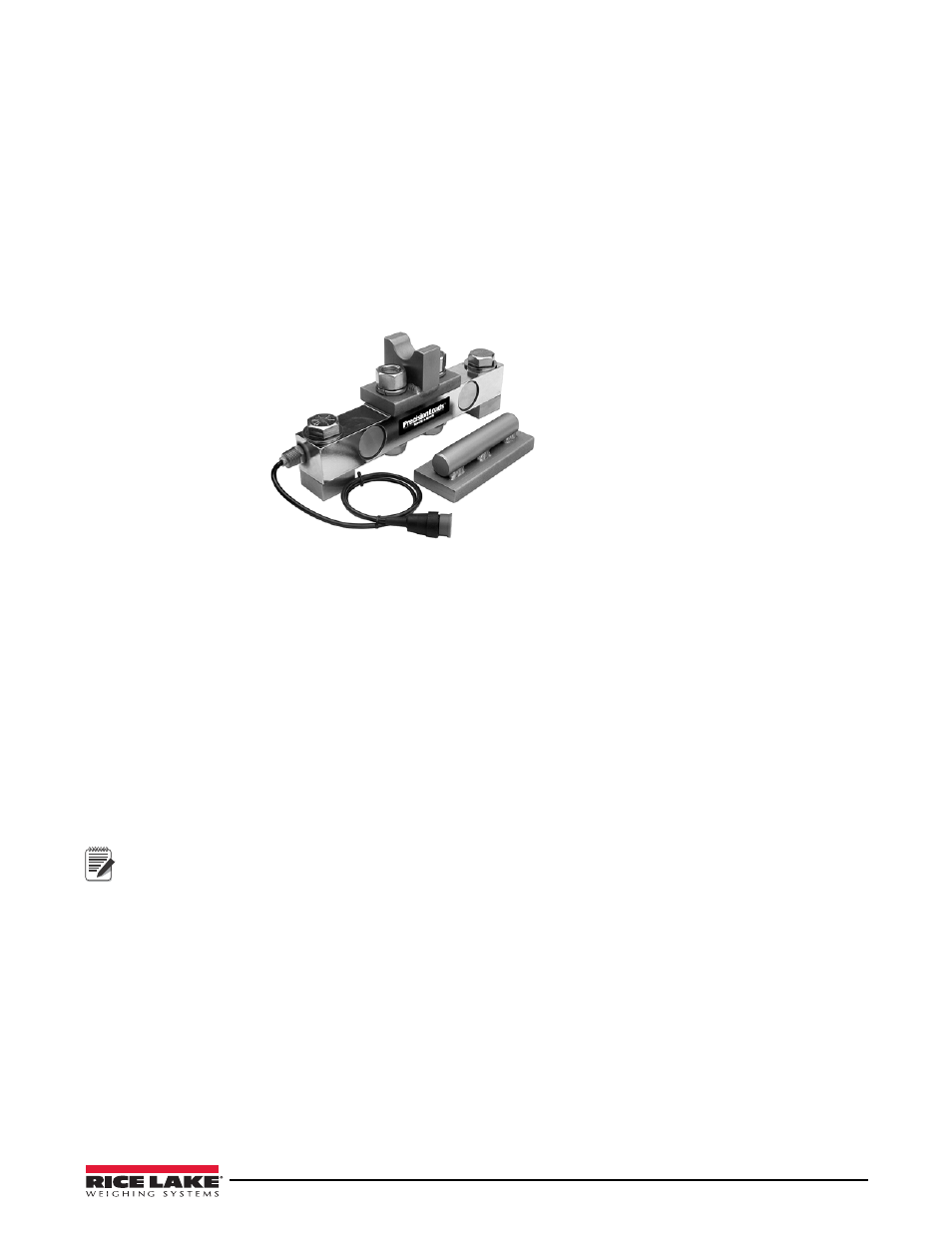

Figure 4-37. Body Rest Mount Kit for Live Weigh Applications

The kits are furnished with groove lock hardware components as shown in Figure 4-37.

4.7.1

Installation Procedure

1. Install the pivot pins at the rear hinge points as instructed in “Hinge and Hoist Pivot Pin Installation” on

page 32, except the hinge pivot bracket is removed and a 3/4" (19 mm) or 1" (25 mm) spacer is installed on

each side to elevate the body or hoist chassis subframe, off of the main chassis rails.

2. Position 2 or 4 spacer blocks of 3/4" or 1" thickness at the desired load cell positions at the front (and

middle if a six point) of the body or hoist chassis subframe. The entire subframe should now be off the

main chassis, equally on all sides.

Note

Any remaining pressure in the lift cylinder(s) should be bled off.

3. Locate and mark positioning for the load cell mounts on each side of the chassis and body or hoist

subframe rails.

4. Clamp chassis angles to the truck frame rails on each side in the desired locations (front and center

mounts). Location of the chassis bracket should avoid and rotation or movement of the lift cylinders from

relaxed to fully upright position, as well as chassis-mounted items that are not easily moved, and should

attempt to utilize as many preexisting chassis bolt holes as possible (to minimize the drilling of new holes).