Rice Lake Combination System - Precision Loads On-Board Weighing Systems User Manual

Page 23

Applications

19

Spacing

For the PL9000-14, PL9000-14.4, and PL9000-16 models, spacing between load cell centerlines should typically

be in the approximate range of 100 inches (254 cm). For the PL9000-22 and PL9000-26 load cells, spacing

between load cell centerlines should not exceed 144 inches (365 cm). These are general guidelines only. Body

subframe strength should determine load cell spacing and the amount of subframe reinforcing required. The

installer must make these determinations. See Section 4.2.3 on page 22 for reference.

Body Angles

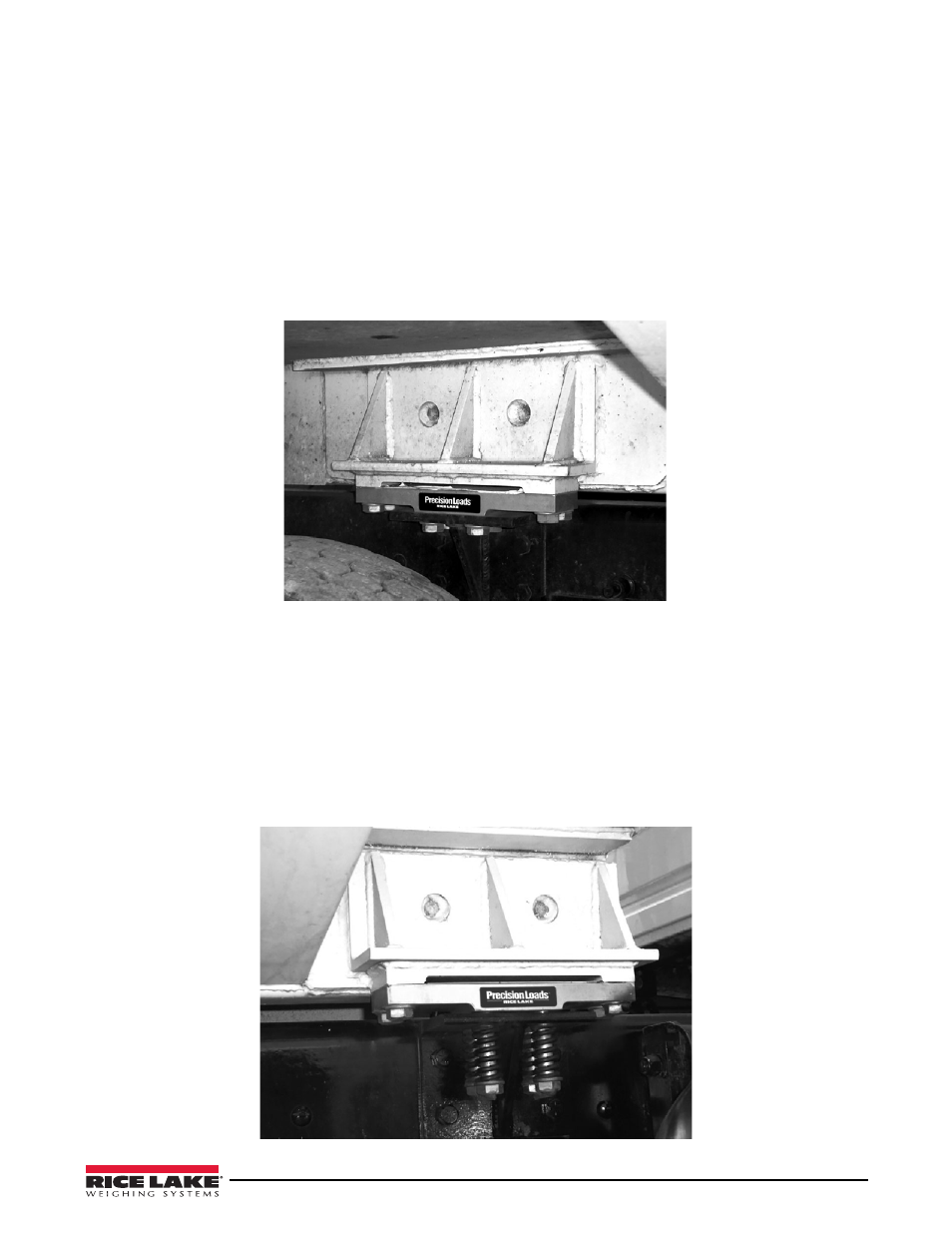

Bracket material used is typically 6" x 4" x 1/2" thick angle, with the 6" flange mounted to the chassis or body

runner. Do not use material that is less than 1/2" thick. Angle bracket length is a minimum of 16" for the

PL9000-14.4 load cell, and 15" for the PL9000-14 cell shown in Figure 4-12 but for weaker body subframes,

longer angles (up to 35" long) as well as other reinforcing techniques may be considered.

Figure 4-12. Body Angle Bracket for the PL9000-14 Load Cell

Body Spring Mounts

For 4-point underbody installations, the front two load cells are mounted with coil springs. For 6-point

installations, the front four cells are mounted with coil springs. Coil springs have an uncompressed height of 3

inches for both the 3/4" springs and for the 1" body coil springs. When mounting the coils, compress the springs

using the bolts supplied by 1/4 to 3/8 inch. The installer must also be aware of thread depth of the bolts used to

mount springs. When using 1/2" angle, and the tabbed washer plate supplied, compressing each coil by 1/4" to 3/8"

allows for the 1"-14UNF x 4.50" bolts of the PL9000-14.4 assembly to thread 1.125 inch into the load cell bolt

holes. See Figure 4-15. For the PL9000-14 load cell assembly (Figure 4-14) compressing the 3/4" coil by 3/8"

allows for the 3/4" PL9000-16UNF x 4.00"L bolts to thread 0.75" into the load cell.

Figure 4-13. PL9000-14 Load Cell Coil Spring Mount Assembly