2 trailer body preparation, Trailer body preparation – Rice Lake Combination System - Precision Loads On-Board Weighing Systems User Manual

Page 30

26

Precision Loads On-Board Weighing Installation & Service Manual

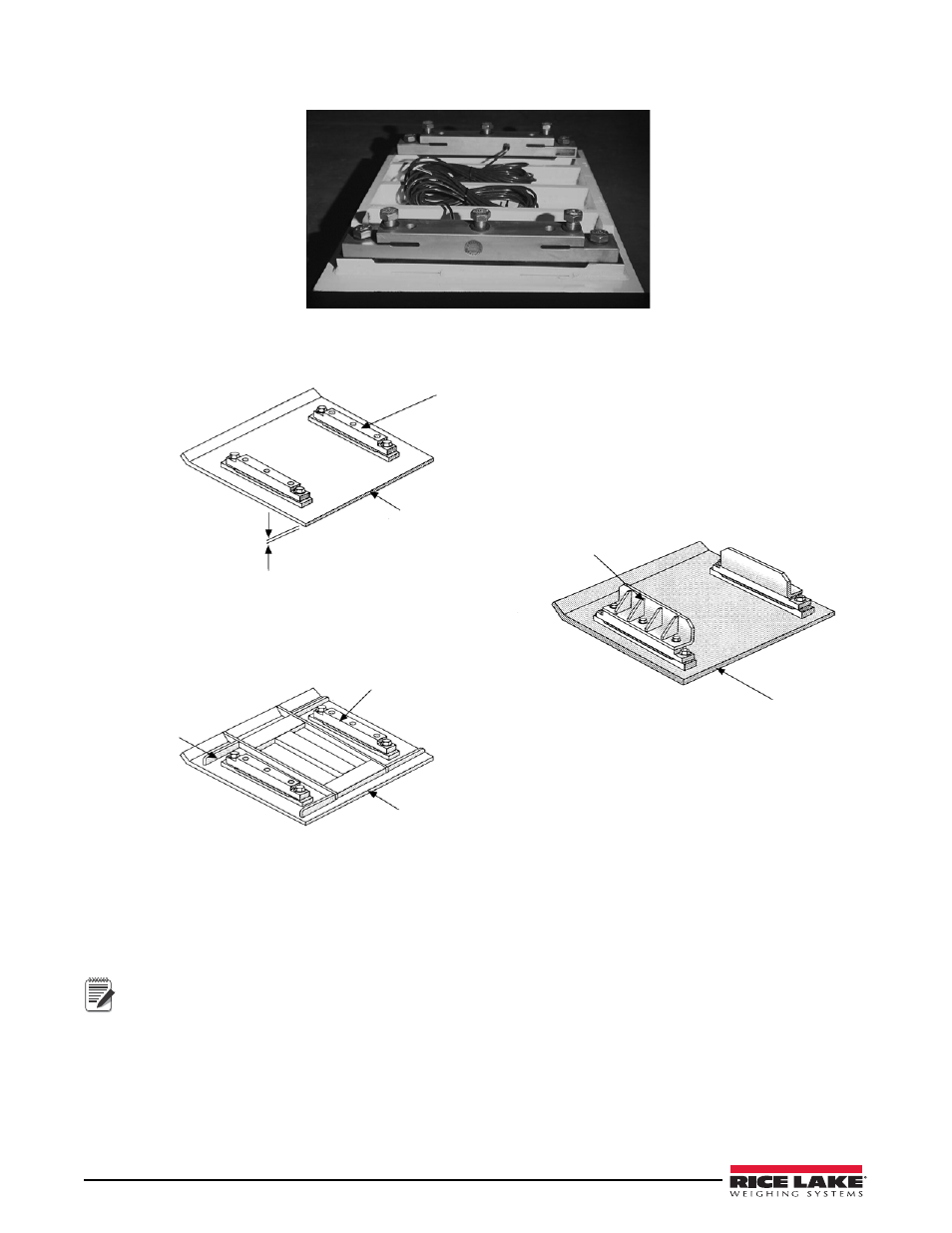

Figure 4-22. Kingpin Reinforced

Load Sensor Mounted

Outboard of the 5th Wheel

Kingpin Skid Plate

1” Thick

Load Sensor / Body

Mounting Bracket

Assembly

Kingpin Skid Plate

Gussets

Load Sensor Mounted

Outboard of the 5th Wheel

Kingpin Skid Plate

REINFORCED SKID

PLATE PLACEMENT

THICK PLATE

MOUNTING

PLACEMENT

NOTE: Access to all mounting

bolts for maintenance is important.

Figure 4-23. Kingpin Installation

4.3.2

Trailer Body Preparation

General

Brackets are generally required to mount load cells to the subframe of the body. These brackets are typically

welded in place, however the installer must ensure that the trailer subframe is acceptable for weld-mounting prior

to welding to any frame.

Note

In the case of aluminum body subframes, the installer must glove the aluminum subframe with a bolted steel

liner to which the load cell angles will be welded. Typically, such glove sections will use 3/8 inch (10 mm)

material and will be professionally lined with materials that prevent electrolysis between steel and aluminum.

Trailer subframe crossmembers are commonly located in the area of the kingpin plate. If existing crossmembers

will interfere with the recommended positioning of the load cells as described herein, then re-positioning of the

crossmembers may be required to allow for correct positioning of the load cell mounting angles.

Since crossmembers provide rigidity to the trailer subframe, it is important for the installer to locate load cell

mounting brackets close to the crossmembers if possible, thus enhancing the structural strength of the installation.

Longer mounting angles to the body subframe add to added installation rigidity.