Section 4:dynamic starter sill prep and install – EFCO 8750XD User Manual

Page 19

EFCO 2012

Page 19

Series 8750XD Unitized Curtain Wall Installation Instructions

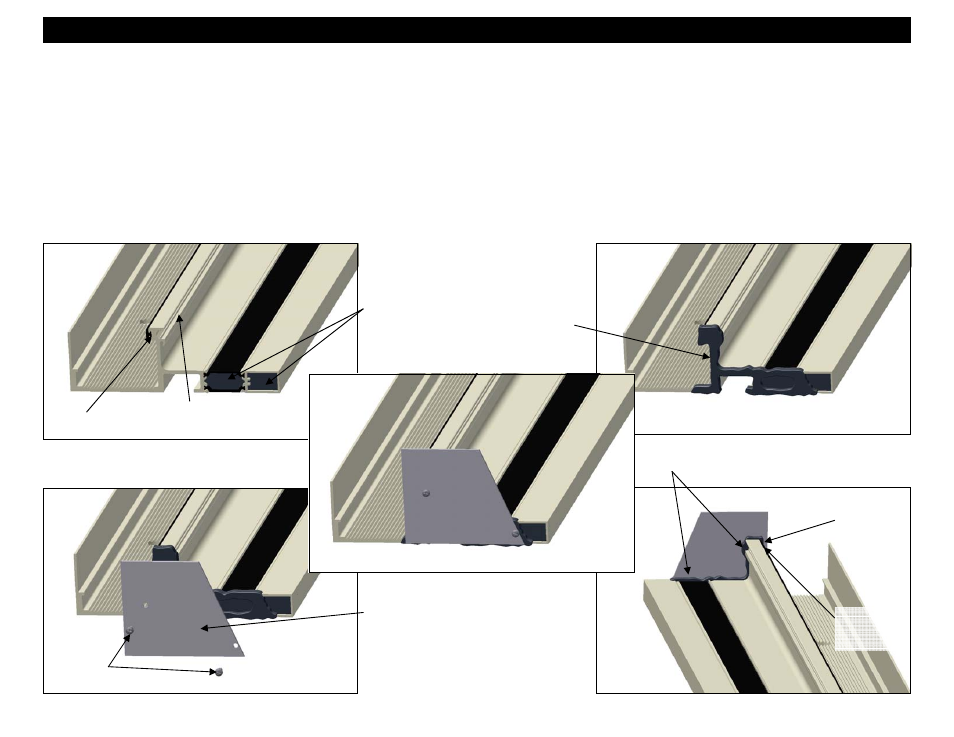

Section 4 - Dynamic Starter Sill Preparation and Installation

1. Preparation of the Dynamic Starter Sill:

a. The dynamic starter sill may have an end dam pre-attached and sealed at the jamb condition. Ensure that the end dam is properly applied and

sealed to the starter sill as described below. This is a critical seal and the joint must be carefully tooled to create a watertight seal. See Figures 23

thru 27.

b. The starter sill may have LC23 spacer pre-applied. The LC23 is cut to the length of the starter sill. The WEA2 gasket will not be applied at this point

it will be applied once all sections of the sill are set to avoid having unnecessary seams or splices. This will be covered later in these instructions.

c. Plug the both ends of the tubular sections of the starter sill by recessing backer rod at least 1/4” into the end of the tube. Fill the voids in the tube and

between the thermal struts with sealant and tool smooth.

Clean all sealant contact surfaces using an approved solvent or cleaner of all oils and other contaminants. The sealant manufacturer’s

preparation and application instructions should be followed exactly. If sealant primer is required, apply it per the primer/sealant

manufacturer’s instructions.

LC23

Spacer

Pocket for

WEA2

FM55 End Dam

Attach with

(2) STC7

Figure 23

STC7

Tool sealant smooth

into joints.

Plug with backer rod

and fill the voids in

the tube and between

the thermal struts

with sealant and tool

sealant smooth.

Figure 24

Figure 25

Figure 26

Silicone Sealant

along profile to be

covered by end

dam

Ensure LC23

Butts into the

end dam

fully.

Figure 27

Back Seal

End Dam to

Starter Sill