EFCO 8750XD User Manual

Page 15

EFCO 2012

Page 15

Series 8750XD Unitized Curtain Wall Installation Instructions

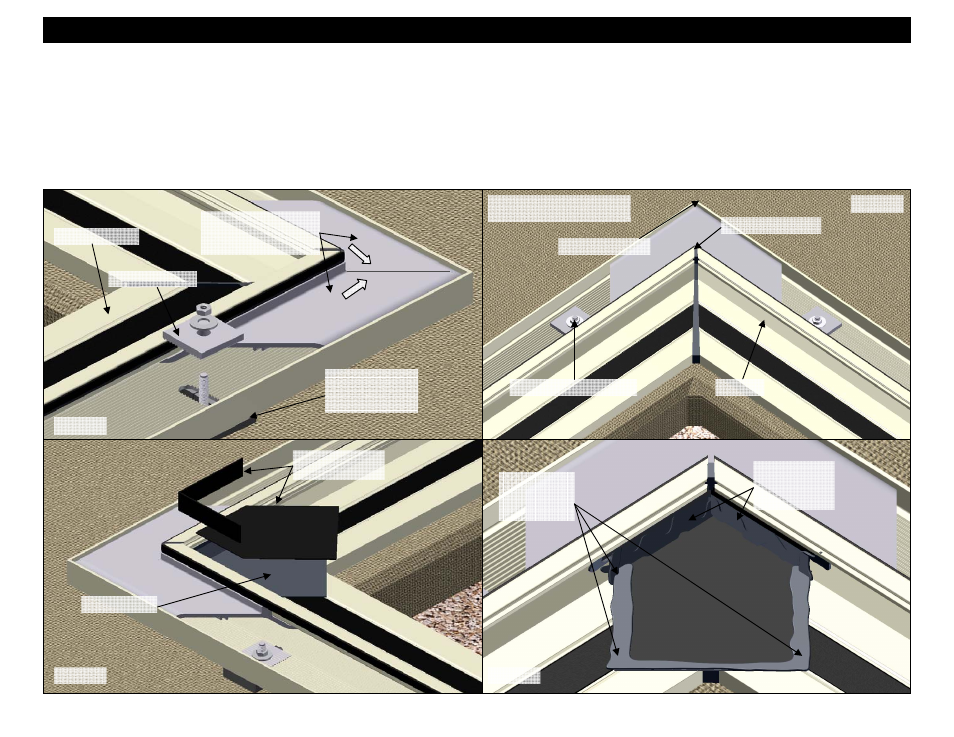

8. Using an approved solvent or cleaner, clean the sealant contact surfaces of the corner splice joint of all oils and other contaminants.

9. The starter sill will be spliced at corner conditions. Refer to the approved shop drawings for project specific joint size.

10. Anchor the new starter sill section ensuring the starter sill is level and while maintaining the appropriate joint size at the splice joint.

11. Slide the base anchors into the corner, butting them together.

12. Apply sealant into the joint between the sections of starter sill and tool smooth to create a water tight seal. Use backer rods in the joint where appropriate.

The splice joint width will vary per project requirements. See Figure 11.

13. Apply a bed of sealant over joint then and use pieces cut from HC13 silicone splice sheet to cover joint. Apply sealant around the edges and seams of the

pieces cut from the splices sheet. See Figures 12 and 13.

Section 3 - Static Starter Sill Preparation and Installation (90° Inside Corner)

Figure 10

Seal over all

edges of

splice sheets.

Static Starter Sill

Bed of sealant

Serrated Washer

Anchor bolts as required.

Shim starter sill to

proper elevation

height.

Pieces of Silicone

Splice Sheet (2)

Slide base anchors into

final position before

securing anchors.

Sealant

Figure 12

Figure 13

Figure 11

90° Inside Corner

Butt Joint Typical

Seal over all

seams between

splice sheets.

Back seal down leg