Critcal final cap seals – EFCO Special Purpose Windows Installation User Manual

Page 47

EFCO 2014

8

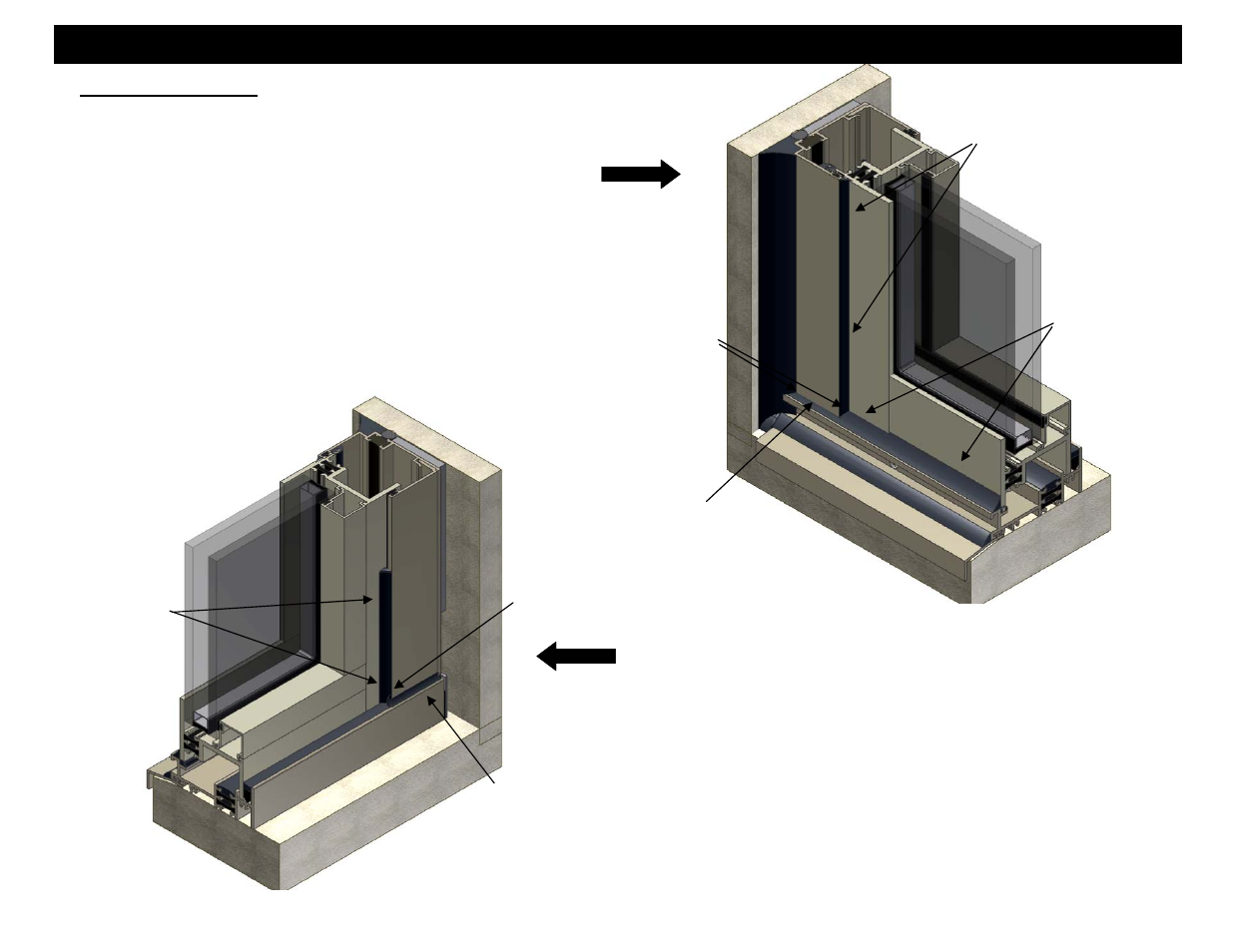

Window Installation Instructions - Typical Subframe Installation Section

Critcal Final Cap Seals

Cap bead the subsill to window joint at the exterior. Join this bead to the

subjamb to jamb condi on seal. Tool smooth and visually inspect for

pinholes. This cap seal is require and should under no circumstance be le

out.

Next cap bead the subjamb to window joint at the exterior. Join this seal to

the cap seal that was just run at the subsill. This cap seal is the preferred

method to seal the exterior of the window to the subjamb, as it is a visual

seal, which can be inspected for con nuity. (An alternate to this subjamb

cap seal is the back bead shown on page 5)

Follow same procedure at the subhead to window joint at the exterior.

Cap bead the subjamb to window joint at the interior at least 6” up from the

subsill. (Note: this cap bead may be ran up the en re length of the subjamb)

Join this seal to the cap seal that is covering the dart at the subsill. This cap seal

is the preferred method to seal the interior of the window to the subjamb, as it

is a visual seal, which can be inspected for con nuity. (An alternate to this

subjamb cap seal is the back bead on the closure shown on page 7)

Run a bead of sealant where the jamb closure meets the subsill. Join this to the

ver cal cap seal and the subsill dart seal. Tool and visually inspect for pinholes.

Seal interior leg of the subframe to the jamb condi on around the en re

perimeter of the opening. In addi on to this seal being cosme c it will aid in

stopping air infiltra on out of the wall cavity.

Cap bead subsill

to window joint

(cri cal)

Cap bead subjamb

to window joint

Seal subjamb

to subsill

Join sealant lines

Cap bead subjamb

to window joint at

least 6” up from

subsill

Seal subjamb

to subsill

Join sealant lines