Before leaving the saw, Additional safety instructions for, Cross cut type cuts – Craftsman 113.298761 User Manual

Page 30: Before starting, While cutting, Work helpers, Auxiliary fenceawork support, Safety for, Saw operations, Basic saw operation - using the miter gauge

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

BEFORE LEAVING THE SAW

1. Turn the saw off.

2. Wait for blade to stop spinning.

3.

workshop chikf-pnoof. Lock the shop. Discon

safety for

basic

saw operations

nect master switches. Remove the yellow Switch

Key. Store it away from children and others not

qualified to use the too).

4. Unplug the saw.

basic saw operation - using the miter gauge

CROSSCUTTING,

MITER

CUTTING,

BEVEL

CUT

TING, COMPOUND MITER CUTTING and when RAB

BETING across the end of a narrow workpiece, the

MITER GAUGE IS USED.

WARNING: For your own safety, always obsenre the

following safety precautions in addition to the safety

instnictlohs on pages 2,3,4,

5,

28,29 & 30.

ADDITIONAL SAFETY INSTRUCTIONS FOR

CROSS CUT TYPE CUTS

Before Starting;

1. Never use the Rip Fence when crosscutting.

2.

An auxiliary woodfacing attached to the MiterGauge

can help prevent workpiece twisting and t h rowbacks.

Attach it to the holes provided. Make the facing long

enough and big enough to support your work. Make

sure, however, it will not interfere with the sawblade

guard.

3.

Use jigs or fixtures to help hold any piece loo small

to extend across the fuli length of the Miter Gauge

face during the cut. This lets you properly hold the

Miter Gauge and workpiece and helps keep your

hands away from the blade.

While Cutting:

1. To avoid blade contact, always hold the Miter Gauge

as shown in the "BASIC SAW OPERATIONS -

USING THE MITER GAUGE."

WORK HELPERS

Before cutting any wood on your saw, study all of the

“Basic Saw Operations."

Notice that in order to make some of thè cuts, it is

necessary to use certain devices, "Work Helpers”, like

the Push Sttek, the Push Block and the Auxiliary Fence/

Work Suf^rt, which you can make yourself.

After you have made a few practice aits, make upthese

"helpers” before starting any projects. Make the "Push

Stick" first

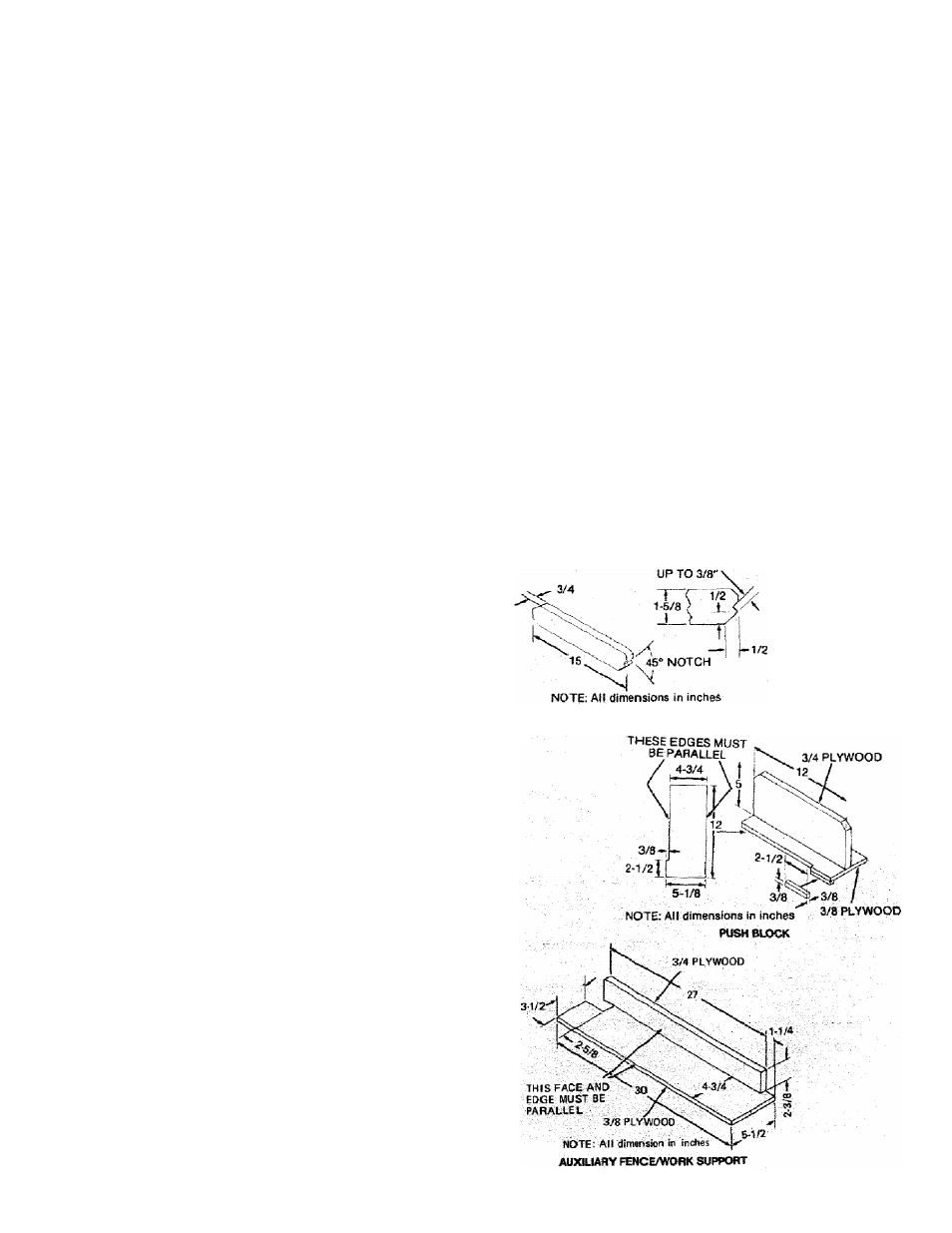

PUSH STICK AMD PUSH BLOCK

Make the Push Stick using a piece of 1 x 2.

Make the Push Block using a piece of 3/8 in. and 3/4 in.

plywood.

The small piece of wood 3/3 x 3/8 x 1-1/2 inches should

be GLUED to the plywood. DO NOT USE NAILS. This

is to prevent dulling the sawblade in the event you

mistakenly cut into the Push Block.

Position the handle in the center of the plywood and

fasten together with glue and woodscrews.

AUXILIARY FENCEAWORK SUPPORT

Make one using a piece of 3/8 inch and 3/4 inch plywood.

Fasten together with glue and woodscrews.

NÓTE: Since the Push Block is used with the Auxiliary

Fence, the 4-3/4 inches dimensions must be held iden

tica! on both the pieces.

SLIGHTLY LESS THAN

THICKNESS OF WORKPIECE

PUSH STICK

30