0 strain-gage input channel – Cooper Instruments & Systems DFI 1650 Multi-Channel Digital Force Indicator User Manual

Page 30

CF 66

24

Rev. C 2/05

9.3.8 LIMIT.SOURCE Menu Item

This designates the data source of the channel monitored by this limit. Each channel has three data sources: the

live tracking value (TRACK), its highest value (PEAK), and its lowest value (VALLEY).

The options for this menu item are:

• “TRACK” means the live tracking value of the channel.

• “PEAK” means the highest value of the channel since the peak/valley detector was last cleared

• “VALLEY” means the lowest value of the channel since the peak/valley detector was last cleared

9.3.9 LEAVE MENU Menu Item

When the menu item is displayed, press [ENTER] to leave this menu. Press [EXIT] to return to the RUN mode.

10.0 STRAIN-GAGE INPUT CHANNEL

10.1 Features

The Strain-Gage Input channel provides a DC excitation voltage to and accepts millivolts signals from strain-gage

transducers. These millivolts signals are digitized, converted into engineering units, and placed into the track, peak

and valley data values of the channel. Setup and calibration of the channel can be made manually through the

SETUP mode or automatically if the transducers are equipped with Signature Calibration. See “What is Signature

Calibration? In Section 1.4”

The analog-to-digital converter input circuit is ratiometric to the excitation voltage, features adjustable digital, low-

pass filtering, 12- to 18-bit resolution (depending on the filter setting) and has several different mV/V input ranges.

These many input ranges allow ±50,000 count resolution (at the slowest filter setting) across a wide variety of mV/V

input ranges.

Three methods of calibrating the Strain-Gate Input channel to the transducer are available: known-load calibration,

shunt calibration and mV/V calibration. The benefits of each are discussed in “CALIBRATION TYPE Menu Item” in

Section 10.5.4

Two rear panel control inputs can be field-configured for such functions, as remote tare can be field-configured for

such functions as remote tare, disabling peak/valley detection and clearing the peak/valley values. A voltage or

current digital-to-analog output is also provided.

Many diagnostic functions are preformed automatically to insure correct wiring and operation of the transducer.

FP2000 Transducers

The Strain-Gage Input channel has its own internal shunt resistor for use in Shunt Calibration. It is not compatible

with FP2000 mV/V output transducers that are equipped with “Buffered Shunt Calibration”. If you wish to use Shunt

Calibration with an FP2000 transducer, use an FP2000 with Buffered Shunt cal and amplified output (e.g. 5 VDC,

10 VDC or 4-20mA) connected to a DFI’s High-Level Input channel.

10.2 Wiring

Connect the transducer to a Strain-Gage Input channel by wiring it to the 12-pin connector of that channel. The

System Calibration Sheet that shipped with the instrument describes which cards are installed in each channel.

The pin-out for this connector is shown on the following table.

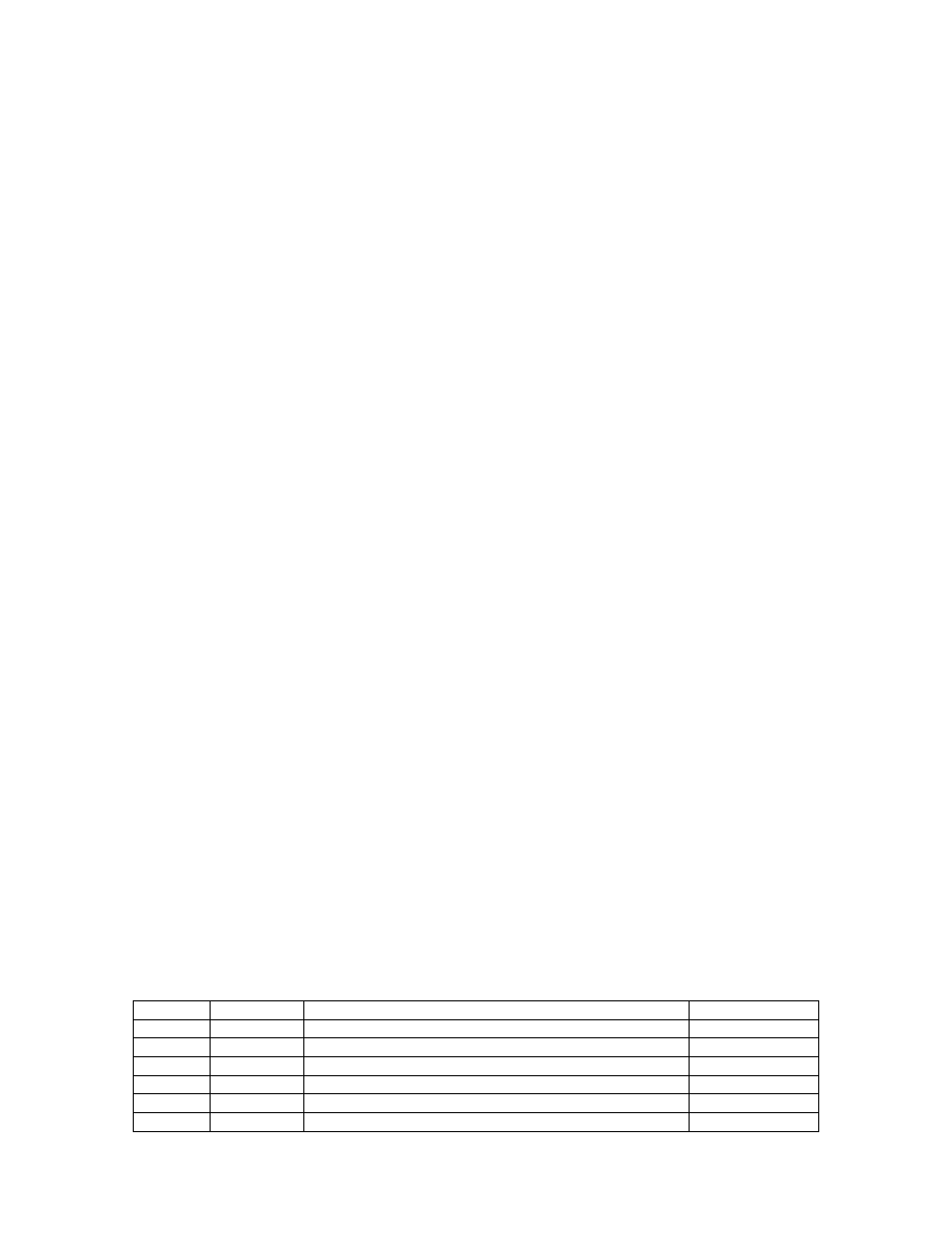

Table 10-1: Strain-Gate Input Channel Pin Connections

Pin Label

Function

Reference

Pin

1 (top)

+EXC

(+) Excitation

10

2 +SEN

(+)

Sense

10

3 -SEN

(-)

Sense

10

4 -EXC

(-)

Excitation

10

5 +SIG

(+)

Signal

10

6 -SIG

(-)

Signal

10