Electric clutch lock-up – Great Plains PFC2000 Operator Manual User Manual

Page 34

32

407-158M

03/28/2007

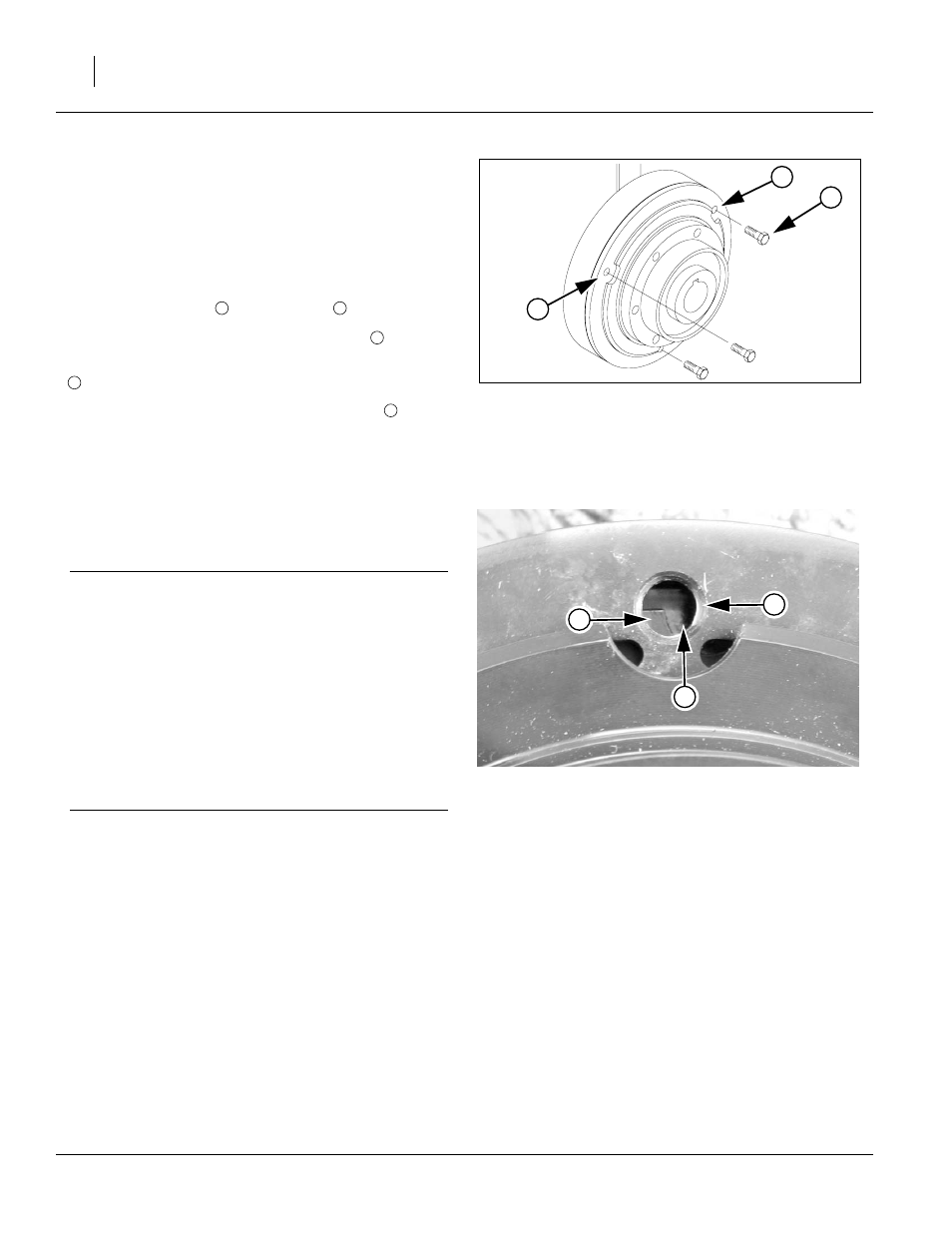

Electric Clutch Lock-Up

Refer to Figure 16 and Figure 17

During system flushing/winterizing, or in case of elec-

tric clutch failure, the electric clutch can be mechani-

cally engaged. If metric bolts required cannot be

located, borrow three from storage locations near the

clutches on the YP2425 planter.

1.

Align the cutouts

2.

Insert M8-1.25

×

14mm long metric bolts

If you observe half the hole obstructed by a metal disc

, you are not at a cutout.

If the entire hole is obstructed by a metal disc

, you

are not at a cutout.

When at a cutout, the bolt will screw in with minimal

resistance until the bolt head reaches the clutch face.

Note: Use only 14mm length bolts. Longer bolts will

damage the clutch. Shorter bolts may not effect a

lock-up.

IMPORTANT !

Clutch lock-up for field operations introduces risks of

spill and/or equipment damage. With the clutch

locked-up, perform:

no highway movements,

no reverse movements,

no movements with planter hitched but seed

monitor off (valves will close),

no movements unhitched from the planter

unless gauge line is open, and

no empty-tank (dry pump) movements.

In lock-up, the pump will be operating whenever the

main cart wheels are turning.

Figure 16

Electric Clutch Lockup

22906

2

3

1

2

3

Figure 17

Clutch Plate Nearly at Cutout

26168

4

1