SARGENT MPower 4000 User Manual

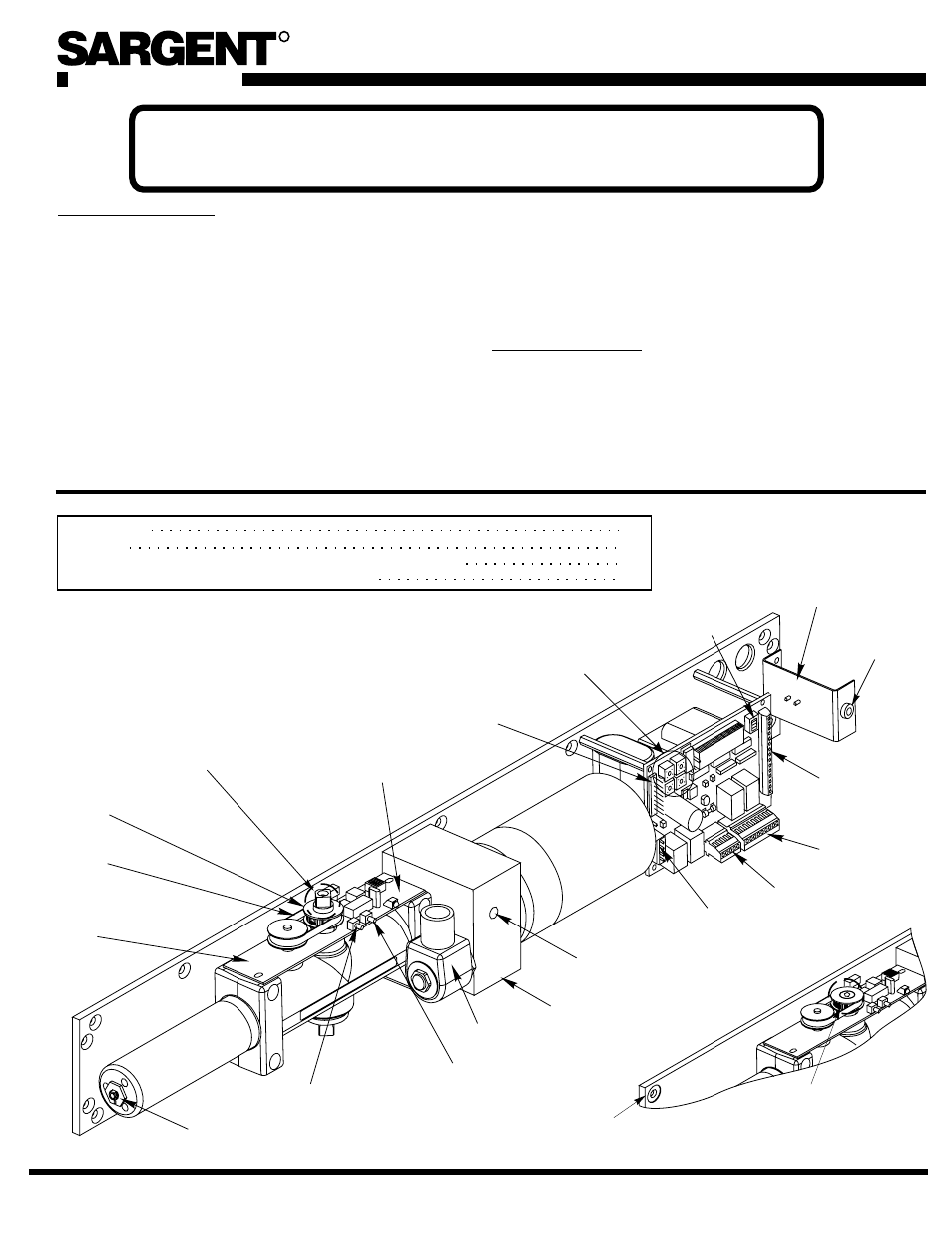

General data, A7666a, Handed unit shown

80-9369-0901-021 (12-02 )

Low Energy Door Operators

Wiring Instructions For 4051, 4052, 4060, 4067

80-9369-0901-021 (12-02 )

120 VOLT POTENTIAL PRESENT. MAKE SURE POWER INPUT TO UNIT IS

TURNED OFF DURING INSTALLATION AND WIRING PROCEDURE.

REQUIREMENTS:

•

•

•

•

U.L. labeled fire or smoke barrier door assemblies require

that the 120VAC, 60Hz power input to the Power Door

Operator

be supplied through normally closed alarm

contacts of the alarm system/alarm panel.

Note:

All wiring and connections use standard wiring practice

conforming with local wiring codes.

Power inputs at terminal strip T1 and at terminal strip JP4 must

be made with copper wire only.

Maximum wire size is:

12 AWG at Power Input Terminal Strips

14 AWG at Terminal Strips JP1 And JP4

No power/voltage inputs are to be made to the Door

Operator unit except 120VAC, 60Hz (+10% -15%) at terminals

HOT and COM of the Power Input Terminal Strip T1.

GENERAL DATA:

•

•

•

Typical field connections for flexible conduit illustrated on page 2.

Power input terminal strip T1 at terminals Hot and COM must be

120VAC at 60Hz (+10% -15%).

Current draw at auxiliary contact JP4 – 2 must not exceed 0.500

amps, for auxiliary devices.

•

•

Maximum current draw of Door Operator units without peripheral

sensors or scanners is 1.5 amps when motor is operating, .050 amps

in standby.

Maximum current draw from auxiliary devices is 0.500 amps

(terminals JP4 – 1 and JP4 – 2).

Fuse “F2” protects the Electronic Control Module and Transformer

circuit and is a 3 amp slow blow fuse.

11/16" Power

Adjustment Nut

JP2

Terminal

Strip

SW1

Dip

Switches

Main Board

Bracket for

Input Power

Terminal Strip

T1

JP1

Terminal

Strip

JP4

Terminal

Strip

JP5

Terminal

Strip

JP3

Terminal

Strip

(SC) Speed

Control Valve

Application

(REF)

Solenoid

Rotary Switches/

Timer Pots

ELS Board w/

ELS Board

Pulley

Spindle Timing

Pulley for Field

Reversible

Units

ELS Board

LED

Door Calibrate

Open Position

Door Calibrate

Close Position

Timing Belt

SC

PUS

H

Fuse

F2

Field Reversible

Unit Shown

Square Spindle End

Protrudes

Spindle Timing

Pulley

Handed Units

Handed Unit

Shown

R

A7666A

Requirements

Unit Wiring

Control Module Layout and (Input/Output Connections; Functions)

Typical Application – Point to Point Wiring Diagrams

1

2

3-5

6-15

1