Carrier FLOTRONIC II 30GN040-420 User Manual

Page 70

REPLACING DEFECTIVE

PROCESSOR MODULE

The replacement part number is printed on a small label

on the front of the PSIO module. The model and serial num-

bers are printed on the unit nameplate located on an exterior

corner post. The proper software and unit configuration data

is factory installed by Carrier in the replacement module.

Therefore, when ordering a replacement processor module

(PSIO), specify complete replacement part number, full unit

model number, and serial number. If these numbers are not

provided, the replacement module order is configured in-

stead as a generic Flotronic II replacement module. This re-

quires reconfiguration of the module by the installer.

Electrical shock can cause personal injury. Disconnect

all electrical power before servicing.

Installation

1. Verify the existing PSIO module is defective by using

the procedure described in the Control Modules section

on page 63.

2. Refer to Start-Up Checklist for Flotronic II Chiller Sys-

tems (completed at time of original start-up) found in

job folder. This information is needed later in this

procedure. If checklist does not exist, fill out the

and

configuration code sections on a new check-

list. Tailor the various options and configurations as needed

for this particular installation.

3. Check that all power to unit is off. Carefully disconnect

all wires from defective module by unplugging the 6 con-

nectors. It is not necessary to remove any of the indi-

vidual wires from the connectors. Remove the green ground

wire.

4. Remove defective PSIO by removing its mounting screws

with a Phillips screwdriver, and removing the module

from the control box. Save the screws for later use.

5. Use a small screwdriver to set address switches S1 and

S2 on the new PSIO module to exactly match the set-

tings on the defective module.

6. Package the defective module in the carton of the new

module for return to Carrier.

7. Mount the new module in the unit control box using a

Phillips screwdriver and the screws saved in Step 4 above.

8. Reinstall all 6 wire connectors and the green ground wire.

9. Carefully check all wiring connections before restoring

power.

10. Verify the LOCAL/ENABLE-STOP-CCN switch is in

STOP position.

11. Restore control power. Verify the red and green lights

on top of PSIO and front of each DSIO module respond

as described in Control Modules section on page 63. The

keypad and display module should also begin its rotat-

ing display.

12. Using the keypad and display module, press

to verify that the software version number matches the

ER (engineering requirement) number shown on the PSIO

label.

13. Press

to verify that the 7 factory configuration

codes (CODE 1 through CODE 7) exactly match the codes

listed for this unit model on the component arrangement

label diagram on the control box door. If they are dif-

ferent or are all zeros, reenter the 7 codes. If any changes

are required, the PSIO display becomes blank and

reconfigures itself after pressing the

key while dis-

playing CODE 7. The display returns in approximately

15 seconds.

NOTE: Codes with leading zeros in the configuration

will be displayed starting with the first number greater

than zero.

14. Press

to verify each item is configured as needed

for this particular installation. Table 14 shows the fac-

tory configuration code default settings. Table 14 also

shows the service replacement code default settings which

are used if no model number was specified when order-

ing the replacement PSIO module. It is strongly sug-

gested that the Start-Up Checklist for Flotronic II Chiller

Systems (completed at time of original start-up) be used

at this time to verify and/or reprogram the various op-

tions and configurations required for this job.

15. Press

to verify that the 2 field configuration

codes (codes 8 and 9) match exactly the codes listed on

the label diagram on the control box door. If they are

different, or are all zeros, reenter the 2 codes.

16. After completing the configuration steps outlined above,

restore main power and perform a unit test as de-

scribed in

and

sections on page 38.

17. Complete this procedure and restore chiller to normal

operation by returning the LOCAL/ENABLE-STOP-

CCN switch to desired position.

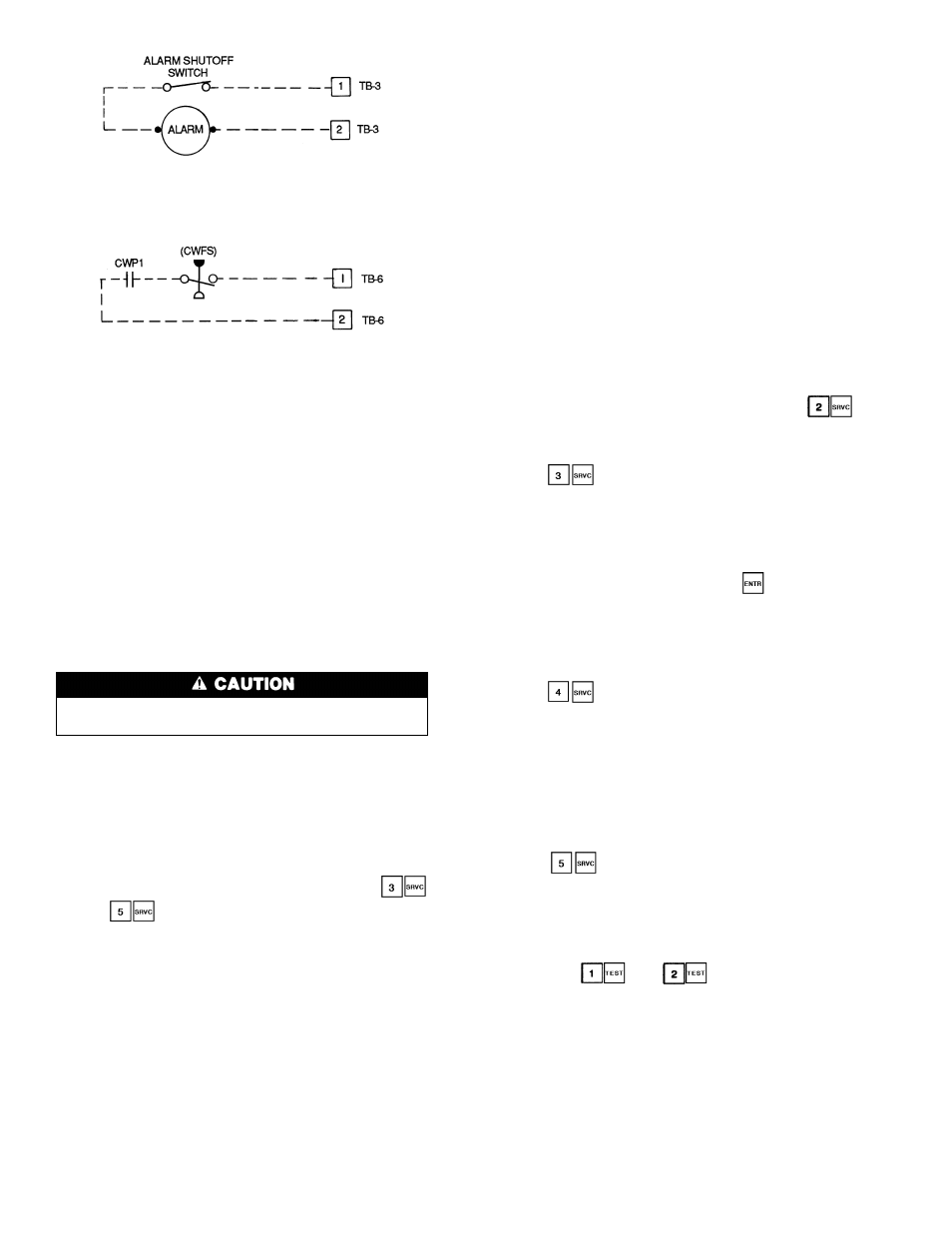

TB — Terminal Block

Fig. 34 — Remote Alarm

CWP1 — Chilled Water (Fluid) Pump Interlock

CWFS — Chilled Water (Fluid) Flow Switch (not required — low flow

protection is provided by Flotronic™ II controls)

TB

— Terminal Block

Fig. 35 — Interlocks

70