Safety considerations, General, Major system components processor module – Carrier FLOTRONIC II 30GN040-420 User Manual

Page 2

SAFETY CONSIDERATIONS

Installing, starting up, and servicing this equipment can

be hazardous due to system pressures, electrical compo-

nents, and equipment location (roof, elevated structures, etc.).

Only trained, qualified installers and service mechanics should

install, start up, and service this equipment.

When working on this equipment, observe precautions in

the literature, and on tags, stickers, and labels attached to the

equipment, and any other safety precautions that apply. Fol-

low all safety codes. Wear safety glasses and work gloves.

Use care in handling, rigging, and setting this equipment,

and in handling all electrical components.

Electrical shock can cause personal injury and death.

Shut off all power to this equipment during installation

and service. There may be more than one disconnect

switch. Tag all disconnect locations to alert others not

to restore power until work is completed.

This unit uses a microprocessor-based electronic con-

trol system. Do not use jumpers or other tools to short

out components, or to bypass or otherwise depart from

recommended procedures. Any short-to-ground of the

control board or accompanying wiring may destroy the

electronic modules or electrical components.

GENERAL

IMPORTANT: This publication contains controls, op-

eration and troubleshooting data for 30GN040-420

Flotronic™ II chillers.

Circuits are identified as circuits A and B, and com-

pressors are identified as A1, A2, etc. in circuit A, and

B1, B2, etc. in circuit B.

Use this guide in conjunction with separate Instal-

lation Instructions booklet packaged with the unit.

The 30G Series standard Flotronic II chillers feature

microprocessor-based electronic controls and an electronic

expansion valve (EXV) in each refrigeration circuit.

NOTE: The 30GN040 and 045 chillers with a factory-

installed brine option have thermal expansion valves (TXV)

instead of the EXV.

Unit sizes 230-420 are modular units which are shipped

as separate sections (modules A and B). Installation instruc-

tions specific to these units are shipped inside the individual

modules. See Table 1 for a listing of unit sizes and modular

combinations. For modules 230B-315B, follow all general

instructions as noted for unit sizes 080-110. For all remain-

ing modules, follow instructions for unit sizes 130-210.

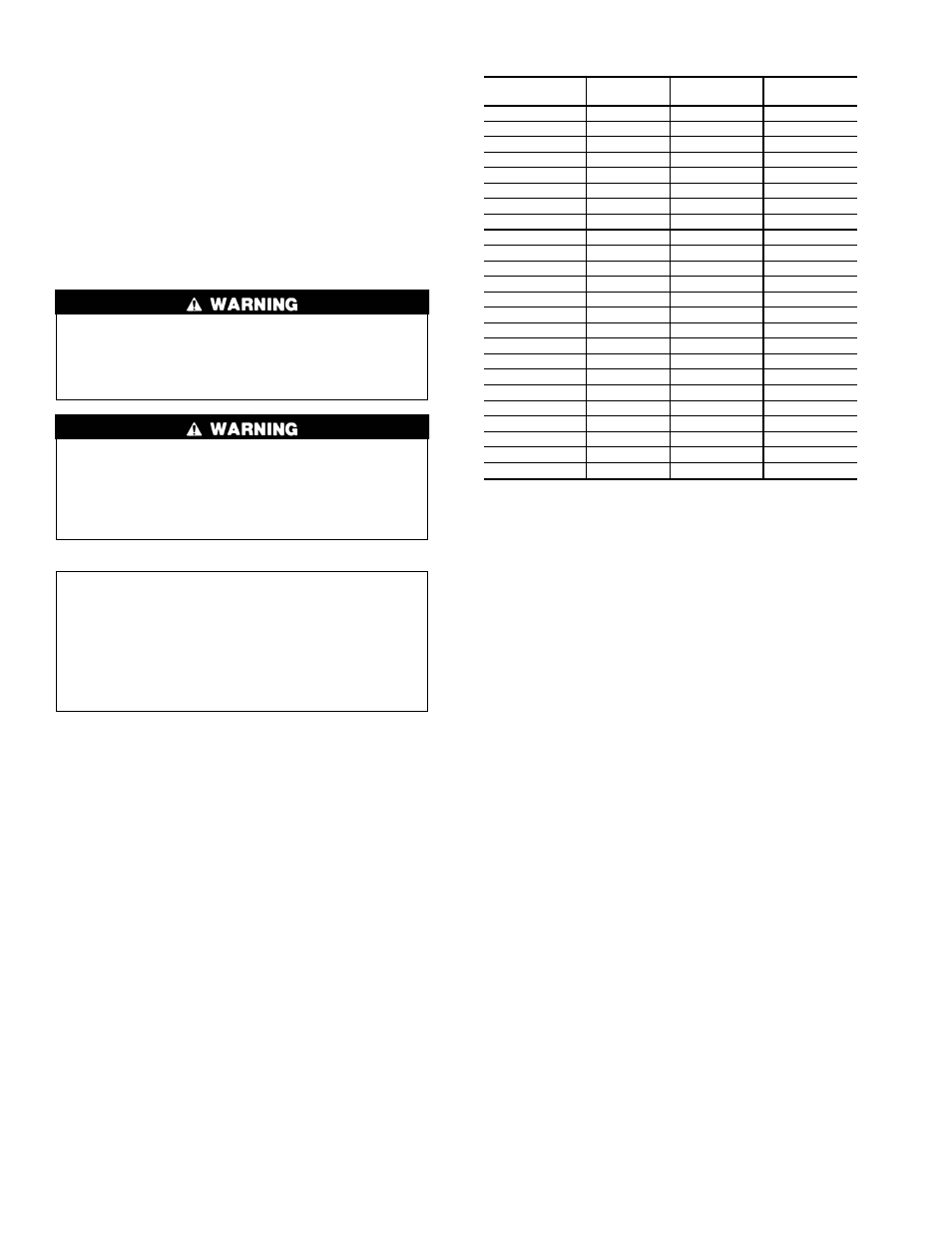

Table 1 — Unit Sizes and Modular Combinations

UNIT MODEL

30GN

NOMINAL

TONS

SECTION A

UNIT 30GN

SECTION B

UNIT 30GN

040

40

—

—

045

45

—

—

050

50

—

—

060

60

—

—

070

70

—

—

080

80

—

—

090

90

—

—

100

100

—

—

110

110

—

—

130

125

—

—

150

145

—

—

170

160

—

—

190

180

—

—

210

200

—

—

230

220

150

080

245

230

150

090

255

240

150

100

270

260

170

100

290

280

190

110

315

300

210

110

330

325

170

170

360

350

190

190/170*

390

380

210

190

420

400

210

210

*60 Hz units/50 Hz units.

The Flotronic II control system cycles compressor un-

loaders and/or compressors to maintain the selected leaving

fluid temperature set point. It automatically positions the EXV

to maintain the specified refrigerant superheat entering the

compressor cylinders. It also cycles condenser fans on and

off to maintain suitable head pressure for each circuit. Safe-

ties are continuously monitored to prevent the unit from op-

erating under unsafe conditions. A scheduling function, pro-

grammed by the user, controls the unit occupied/unoccupied

schedule. The control also operates a test program that al-

lows the operator to check output signals and ensure com-

ponents are operable.

The control system consists of a processor module (PSIO),

a low-voltage relay module (DSIO-LV), 2 EXVs, an EXV

driver module (DSIO-EXV), a 6-pack relay board, a keypad

and display module (also called HSIO or LID), thermistors,

and transducers to provide inputs to the microprocessor. A

standard options module (SIO) is used to provide additional

functions. See Fig. 1 for a typical 30GN Control Panel.

MAJOR SYSTEM COMPONENTS

Processor Module —

This module contains the oper-

ating software and controls the operation of the machine. It

continuously monitors information received from the vari-

ous transducers and thermistors and communicates with the

relay modules and 6-pack relay board to increase or de-

crease the active stages of capacity. The processor module

2