Tweco 400 MSTP Arcmaster User Manual

Page 66

60

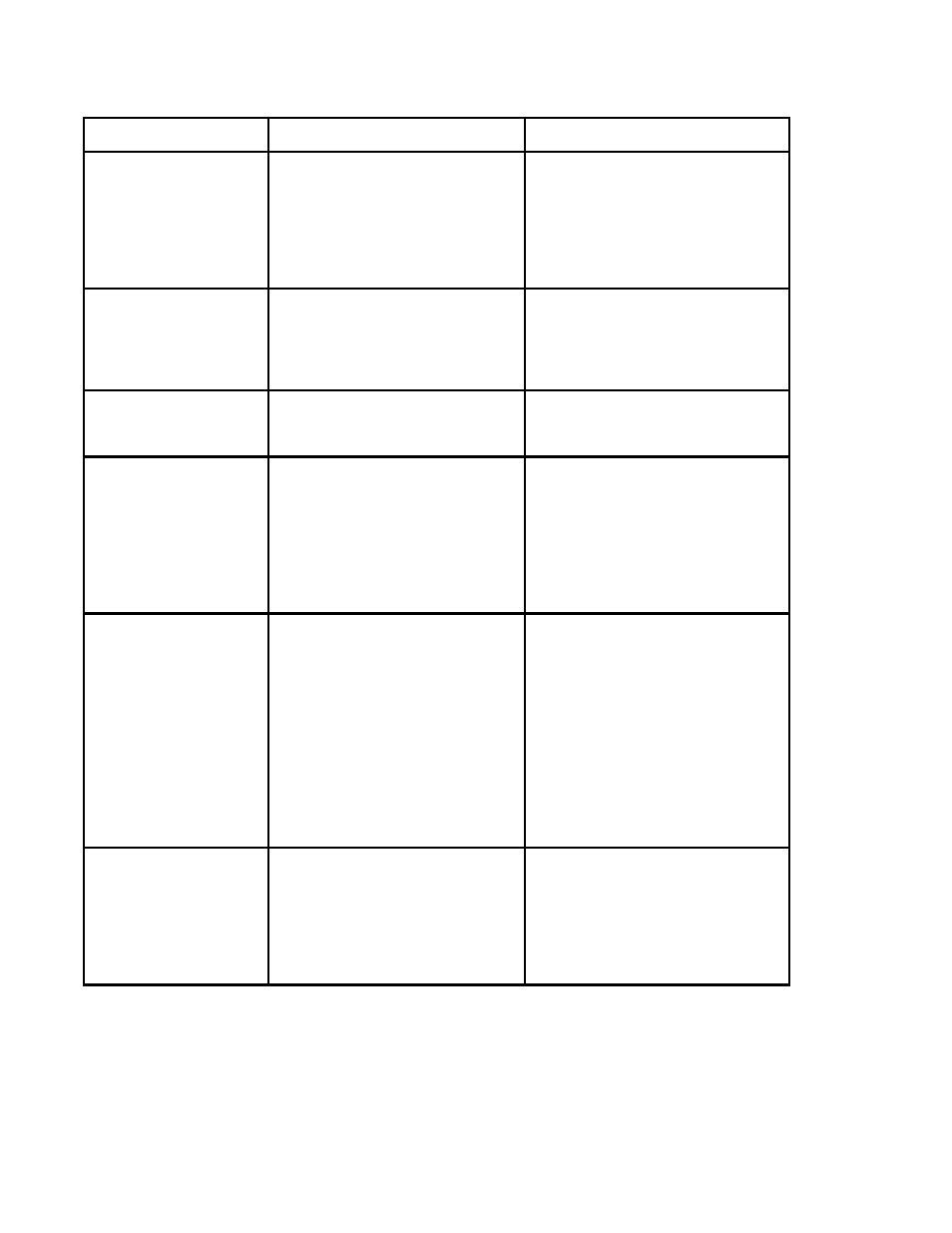

9.05 Power Source Problems

Description

Possible

Cause

Remedy

1 The welding arc cannot

be established.

A

B

The Primary supply voltage has not

been switched ON.

The Welding Power Source switch

is switched OFF.

A

B

Switch ON the Primary

supply voltage.

Switch ON the Welding

Power Source.

C Loose connections internally.

C Have an accredited Thermal Arc

Service Agent repair the connection.

2 Maximum output

welding current

cannot be achieved

with nominal Mains

supply voltage.

Defective control circuit.

Have an accredited Thermal Arc

Service Agent inspect then repair

the welder.

3 Welding current reduces

when welding

Poor work lead connection to the

work piece.

Ensure that the work lead has a

positive electrical connection to the

work piece.

4 No gas flow when the

torch trigger switch is

depressed.

A

B

Gas hose is cut.

Gas passage contains impurities.

A

B

Replace gas hose.

Disconnect gas hose from the rear of

Power Source then raise gas pressure

and blow out impurities.

C Gas regulator turned OFF.

C Turn gas regulator ON.

D Torch trigger switch lead is

disconnected or switch/cable

is faulty.

Reconnect lead or repair faulty

switch/cable.

5 Gas flow won’t

shut OFF.

A Weld Mode (

STD

,

SLOPE

,

REPEAT

or

SPOT

) was changed before

POST-FLOW

gas time had finished.

A Strike an arc to complete the weld

cycle.

OR

Switch machine OFF then ON to

reset solenoid valve sequence.

B Gas valve is faulty.

B Have an accredited Thermal Arc

Service Agent replace gas valve.

C Gas valve jammed open.

C Have an accredited Thermal Arc

Service Agent repair or replace

gas valve.

D

POST-FLOW

control is set

to 60 sec.

D Reduce

POST-FLOW

time.

6

The TIG electrode has

been contaminated due

to the gas flow shutting

OFF before the pro-

grammed

POST-FLOW

time has elapsed.

The Weld Process Mode (STICK, HF

TIG or LIFT TIG) was changed

before

POST-FLOW

gas time

had finished.

Do not change Weld Process Mode

before the

POST-FLOW

gas time had finished.