Tweco 400 MSTP Arcmaster User Manual

Page 64

58

9.04 Stick Welding Problems

Description

Possible

Cause

Remedy

1 Gas pockets or voids in

weld metal (Porosity).

A

B

C

Electrodes are damp.

Welding current is too high.

Surface impurities such as oil,

grease, paint, etc.

A

B

C

Dry electrodes before use.

Reduce welding current.

Clean joint before welding.

2 Crack

occurring

in

weld metal soon

after solidification

commences.

A

B

C

Rigidity of joint.

Insufficient throat thickness.

Cooling rate is too high.

A

B

C

Redesign to relieve weld joint of

severe stresses or use crack

resistance electrodes.

Travel slightly slower to allow greater

build up in throat.

Preheat plate and cool slowly.

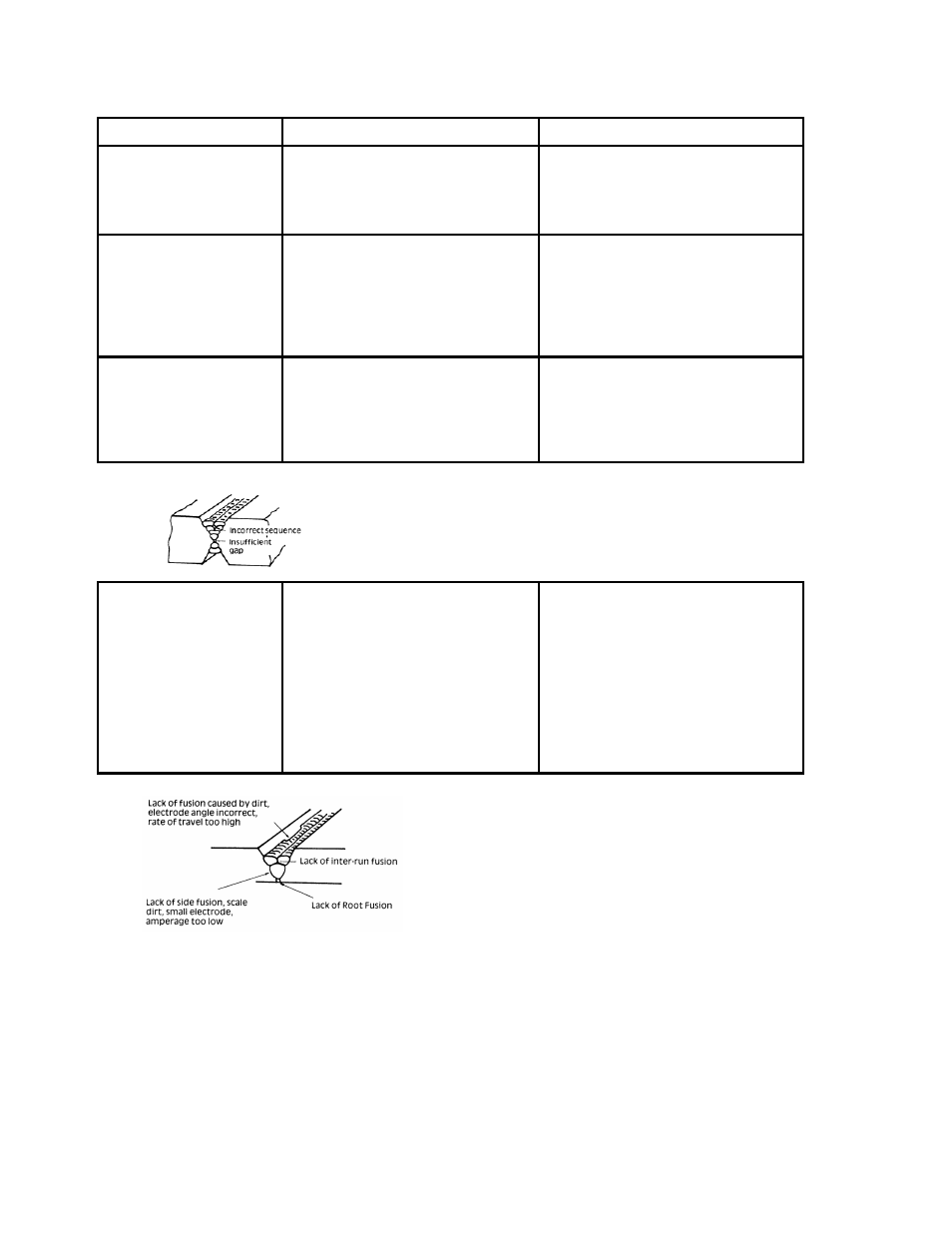

3 A gap is left by

failure of the weld

metal to fill the root

of the weld.

A

B

C

Welding current is too low.

Electrode too large for joint.

Insufficient gap.

A

B

C

Increase welding current.

Use smaller diameter electrode.

Allow wider gap.

D Incorrect sequence.

D Use correct build-up sequence.

Figure 8. Example of Insufficient Gap or Incorrect Sequence

4 Portions of the weld

run do not fuse to the

surface of the metal or

edge of the joint.

A

B

Small electrodes used on heavy

cold plate.

Welding current is too low.

A

B

Use larger electrodes and

pre-heat the plate.

Increase welding current.

C Wrong electrode angle.

C Adjust angle so the welding arc is

directed more into the base metal.

D Travel speed of electrode is

too high.

D Reduce travel speed of electrode.

E Scale or dirt on joint surface.

E Clean surface before welding.

Figure 9. Example of Lack of Fusion