06 selecting the proper electrode diameter, 07 keeping electrodes dry, 08 secondary power cables (welding leads) – Tweco N7500 User Manual

Page 25: System component description n7500

Manual 89250890

3-9

SYSTEM COMPONENT DESCRIPTION

SYSTEM COMPONENT DESCRIPTION

N7500

3.06 Selecting the Proper Electrode

Diameter

Your choice should be based on the depth and width of

the gouge you need. If you want a gouge 1-1/2 times

greater than the diameter of the electrode being used,

make the groove in two or more passes or oscillate

the Torch Head.

3.07 Keeping Electrodes Dry

Keep electrodes dry. Damp electrodes should be dried

before using. (Ten hours at 300°F [176.7°C]) Wet

electrodes may shatter from internal steam pressure

when an arc is struck.

POWER SUPPLY (SUPPLIED BY USER) FOR THE

N7500 SYSTEM

WARNING

Direct current/electrode positive (reverse

polarity) is required for the N7500 Sys-

tem. Use direct current/electrode negative

(straight polarity) for special applications.

DO NOT use alternating current with the

system.

CAUTION

Power Supplies must be rated for 100%

duty cycle at the amperage required for the

size (diameter) electrode used. Contact the

manufacturer of the Power Supply for parallel-

ing procedures or with questions concerning

amperage ratings and duty cycles.

NOTE

Recommendations are based on a 4 volt DC

drop per 100 ft. (30.48 m) length given is one-

half the sum of lengths of electrode and ground

leads. Inadequate grounding may cause cable

overheating. There should be at least 1 square

inch (6.45 cm

2

) of contact per 1000 amps.

DC Welding Power Supply with a minimum Open-Circuit

Voltage (OCV) of 60 volts and 45 volts at rated load supply

the DC current for the N7500 System. Use single Power

Supplies rated at 1,000 or 1,500 amperes to get enough

amperage for larger diameter electrodes. Power Supplies

may be paralleled in combinations of two or more similar

units.

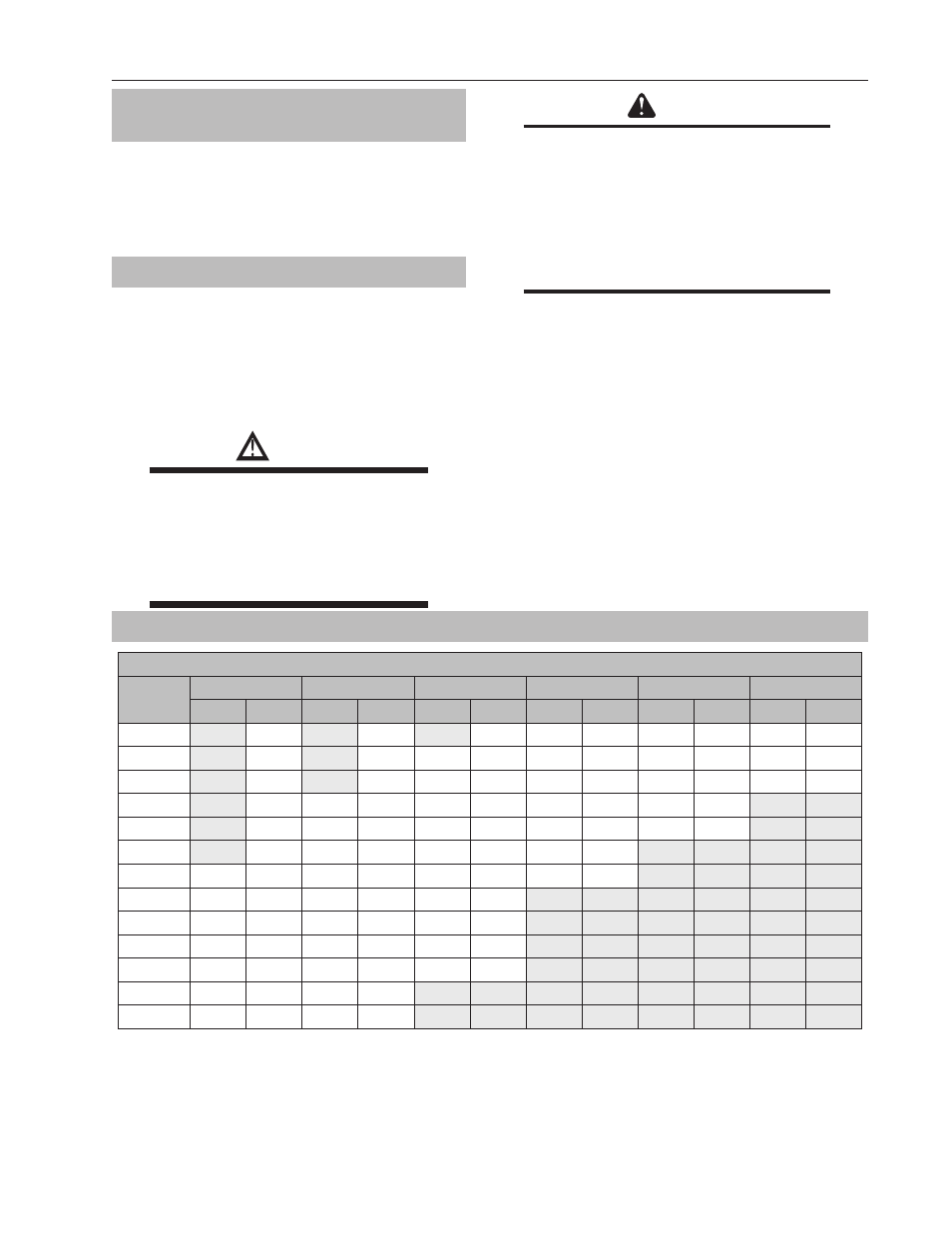

3.08 Secondary Power Cables (Welding Leads)

Recommended Number and Size of Secondary Cables

Amps

25 ft. (7.5 m) 50 ft. (15 m) 100 ft. (30 m) 150 ft. (46 m) 200 ft. (61 m) 250 ft. (76 m)

No.

Size

No.

Size

No.

Size

No.

Size

No.

Size

No.

Size

100

4

4

1

1

1/0

1

2/0

1

4/0

200

3

2

1

1/0

1

3/0

1

3/0

3

3/0

300

2

1

1

3/0

2

2/0

2

4/0

4

4/0

400

2

1

1/0

1

4/0

3

3/0

3

4/0

500

1

1

2/0

2

2/0

3

4/0

4

4/0

600

1

1

3/0

2

3/0

3

4/0

800

1

3/0

1

4/0

2

4/0

5

4/0

1000

1

4/0

2

2/0

3

3/0

1200

2

2/0

2

3/0

3

4/0

1400

2

4/0

2

4/0

4

3/0

1600

3

3/0

2

4/0

4

4/0

1800

2

4/0

3

3/0

2000

3

4/0

3

4/0

Table 3-13: Power Cable Requirements

Choose the number and size of secondary power cables on the basis of the combined length of both the positive

(Electrode) and negative (work piece/ground) cables to ensure greatest efficiency and safe operation in terms of

100% duty cycle.