02 n7500 specifications, 02 n7500 specifications -2, N7500 specifications – Tweco N7500 User Manual

Page 16

SPECIFICATIONS 2-2

Manual 89250890

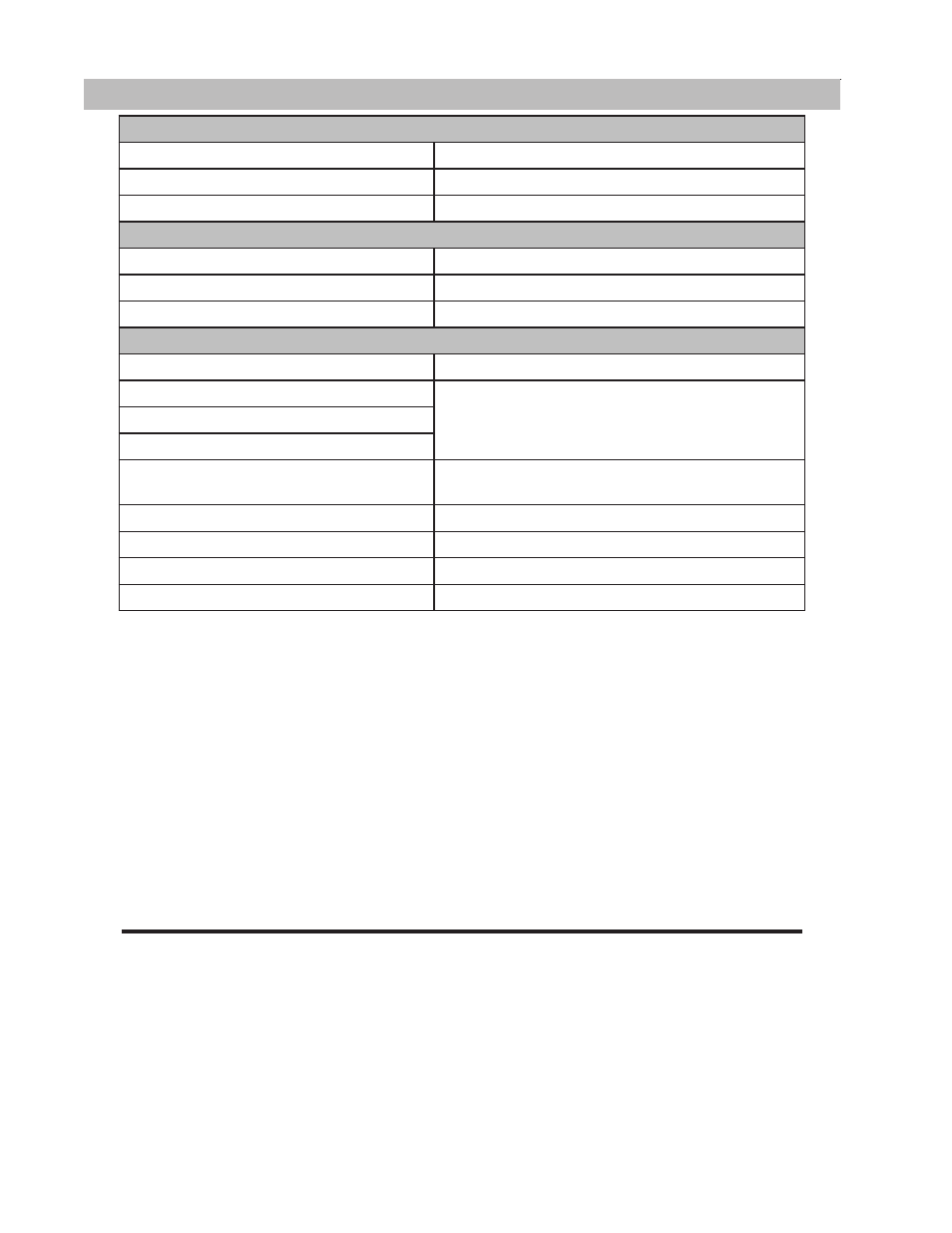

N7500 SPECIFICATIONS

2.02 N7500 Specifications

Rated Output

Output Current

400-1600

Duty Cycle

MAX. 1600A/42V @ 100%

Open Circuit Voltage

Minimum of 60VDC

Rated Input

Rated Input Voltage

110V - 220V

Rated Input Amperage

5A

Input Frequency

50/60 Hz

Control Box Controls

5A Circuit Breaker ON/OFF Switch w/reset

ON/OFF Switch w/reset

110V/220V Control Box Power Input

3-Pin Socket

110V Auxiliary Outlet

4A, 110V

220V Auxiliary Outlet

4A, 220V

(2) 5A Circuit Breaker

1 off push-button circuit breaker for the 110V outlet

1 off push-button circuit breaker for the 220V outlet

Circuit Interface to Remote Pendant

7-Pin Socket

Circuit Interface to Torch Head

6-Pin Socket

Circuit Interface to Power Supply

6-Pin Socket

Signal Interface to Work Piece

1-Pin Socket

Table 2-1: N7500 Specifications

N7500 SYSTEM

The N7500 System produces in a single pass uniform “U” or “J” grooves of various depths up to 1-1/8” (28.6

mm). Two or more passes produce grooves of greater depth. Through continuous control of arc voltage or amper-

age and a constant travel speed, the groove is held within 0.025” (0.635 mm) target depth. Victor Arcair Jointed

Jetrods

®

Electrodes, with tapered male and female ends, make it possible to produce grooves of unlimited length.

Control elements and circuitry for the N7500 System are housed in a Control Box and a splash-proof Pendant.

Gouging operations are managed remotely using the Remote Pendant with a multi-function LCD display and touch

pad controls.

Groove depth and width are controlled in two ways:

• By changing the travel carriage’s forward speed or by changing the work piece rotational speed.

• By changing the electrode’s diameter and increasing or decreasing amperage.

NOTE

Remote Pendant is NOT submersible.

This manual has been structured to provide the user with all the information required for assembly, operation and

troubleshooting of the N7500 System. Illustrations, charts and other supporting data are provided to bridge the

gap between theory and practice.

In addition, the N7500 System can be integrated with any mechanized travel system that provides forward travel

over a steel plate while in the flat, vertical, or over-head positions. The N7500 Torch Head can also be mounted

in a stationary position for work on rotating shafts, round steel, or a vessel. In a stationary set up the work-piece

rotates in a

counter-clockwise direction and the Torch Head is generally located at the work-piece’s 4 o’clock position.

For additional information, contact your local Victor Arcair Distributor or Victor Technologies.