Ultra-cut 300 xt, 08 remote arc starter trouble shooting – Tweco 300 XT Ultra-Cut Plasma Cutting System User Manual

Page 84

ULTRA-CUT 300 XT

4-20

OPERATION

Manual 0-5274

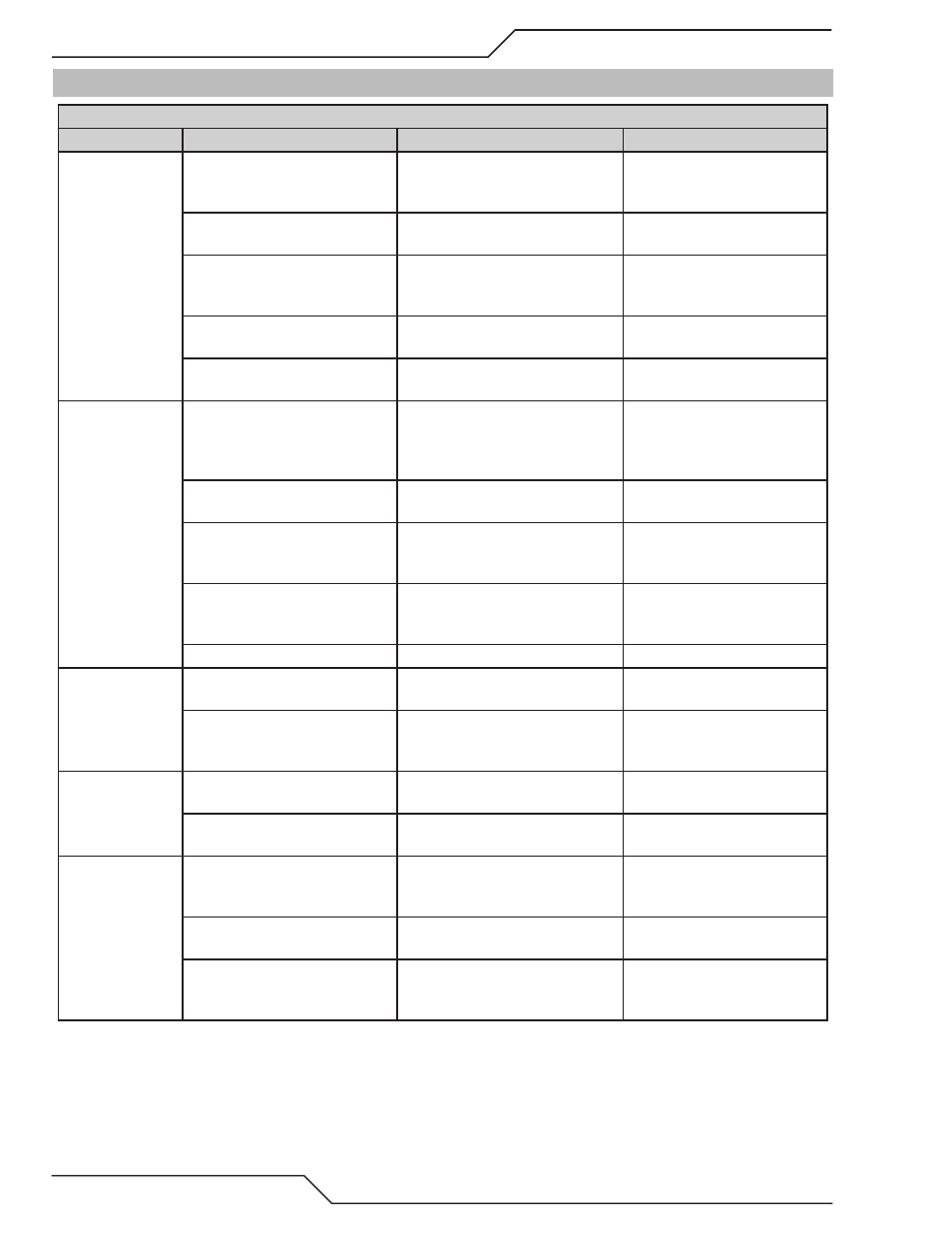

4.08 Remote Arc Starter Trouble Shooting

Arc Starter Trouble Shooting

Symptom

Cause

Check

Remedy

No Pilot ignition

Neon indicator on

Cap board lights

but no ignition.

Pilot return wire not connected

at torch head or broken in torch

lead

Visual inspection, continuity check Connect Wire or replace leads.

Coolant has become conductive

Use conductivity meter

Flush system,

replace coolant.

High Frequency cap (C4 on

Cap PCB) possibly open wires

disconnected.

Use capacitance meter

Reconnect or replace.

Negative supply cable not con-

nected correctly

Visual inspection

Reconnect

Pilot return wire not connected

or loose in arcstarter.

Visual inspection

Connect Wire.

No Pilot ignition:

Neon indicator

not illuminated.

No 120V supply, CB4 of plasma

rear panel tripped

Reset breaker, check for 120 VAC

at the module’s 115V terminals

during ignition time.

Check for shorted cable, defec-

tive circuit breaker, shorted

ignition module input. (see

next symptom)

Electronic Ignition module

shorted input

Resistance measurement, good

module measures about 45 ohms

Replace bad module

No 120V supply, CB4 not

tripped

check for 120 VAC at the plasma

supply’s rear panel connector J59-

7 & 9 during ignition time.

120V present - open control

cable, 120V not present - fault

in plasma power supply

Faulty Electronic Ignition

module

Check for 120 VAC at the modules

115V terminals during pilot igni-

tion time

If 120 VAC is present but neon

not illuminated, module is

defective, replace module

Loose fitting(s)

Visual inspection

Tighten fittings.

Coolant Leaks

Damaged or punctured coolant

line(s).

Visual inspection

Replace Coolant Lines

Supply & return hose reversed

Visual Inspection of color-coded

connections

Match coolant connection

colors

to arc starter fitting colors.

No cooling or

insuf¬ficient cool-

ing: No Coolant

Flow

Blockage in supply/return hoses Loosen fitting slightly and check

for coolant flow

Flush system or replace

blocked hose.

Missing or loose

ground connection

Visual inspection of ground wire

to Arc Starter

Make or tighten connections to

good ground.

Erratic System

Behavior(EMI

Interference

Torch Lead Shield not connected

or loose. F1 gnd cable not con-

nected.

Visual inspection of lead shield

attachment to Arc Starter

Reconnect / tighten lead con-

nectors.

Cap board ground screw not

tight or missing.

Visual inspection

Tighten or replace.

Cap C5 or C7 (on Cap PCB) open

or disconnected wires to Cap

board.

Visual inspection / capacitor

measurement

Replace PCB.