Ultra-cut 300 xt, 11 handling and installation of fiber optics – Tweco 300 XT Ultra-Cut Plasma Cutting System User Manual

Page 35

ULTRA-CUT 300 XT

Manual 0-5274

INSTALLATION

3-11

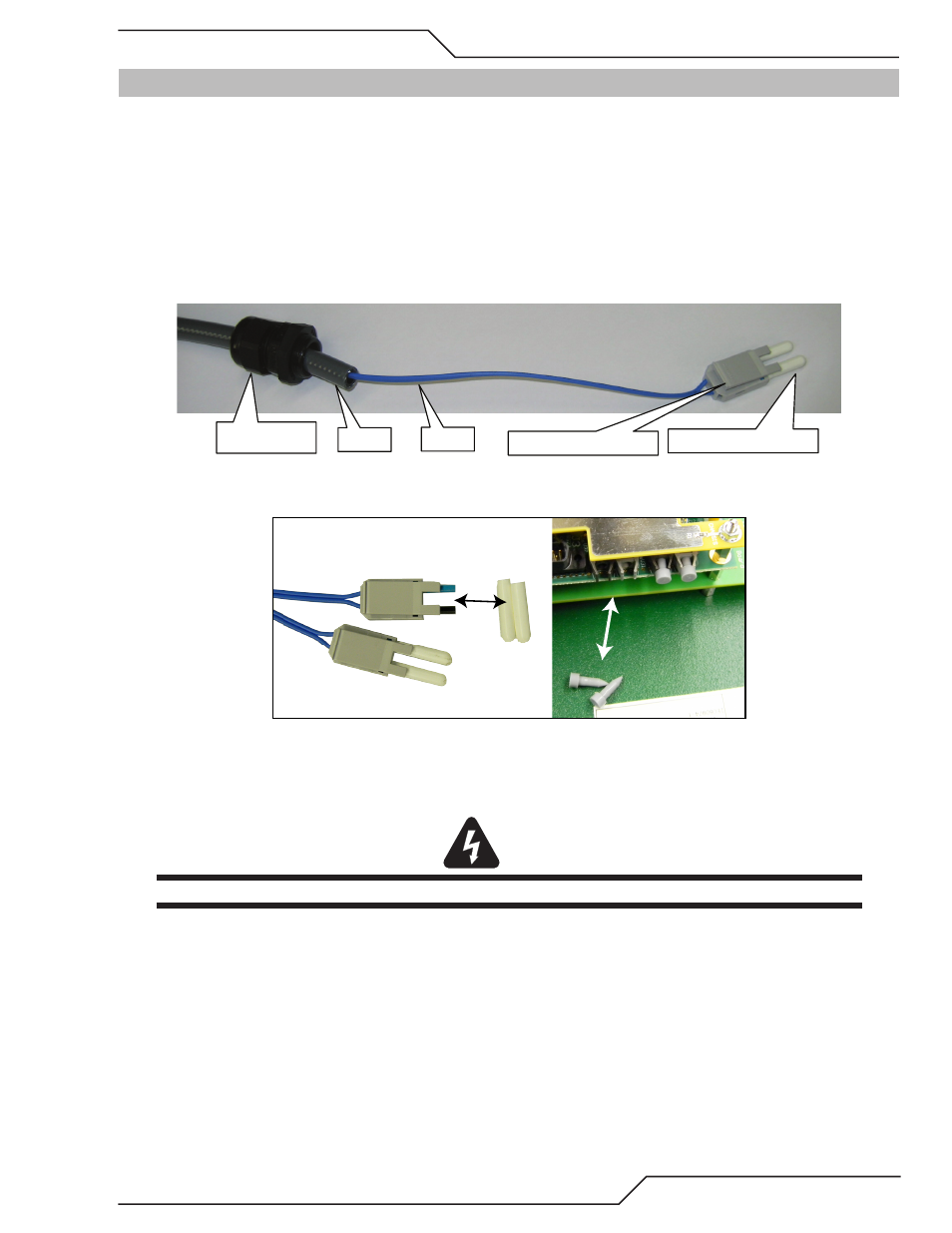

3.11 Handling and Installation of Fiber Optics

General Information

This kit is for proper handling and installation of Fiber Optic Cables used in Thermal Dynamics Ultra-Cut

®

and

Auto-Cut O2

®

automated gas boxes and Gas Control Modules.

Fiber Optic cable is used in place of wire because it offers far superior immunity to electrical noise but it is more

delicate and requires careful handling. With fiber optics, electrical signals are converted to light with a transmit-

ter LED. The light passes down the fiber where it is converted back to an electrical signal at the receiver end. Any

damage to the fiber from sharp bends or pulling that stretches the fiber can reduce it’s ability to transmit light. We

run the fiber inside a hose for most of its length to protect it from abrasion, burning from hot metal or sharp bends

but the ends are exposed and must be handled with care.

Hose

Strain Relief

Fiber

Connector with Latch

Protective End Covers

Art # A-09416

Remove fiber optic end covers and plugs.

Art # A-12015

WARNING

Disconnect primary power at the source.