Ultra-cut 300 xt, Mc2a mc2b, Fan1 – Tweco 300 XT Ultra-Cut Plasma Cutting System User Manual

Page 178

ULTRA-CUT 300 XT

�7�

PPENDIX

Manual 0�5�7�

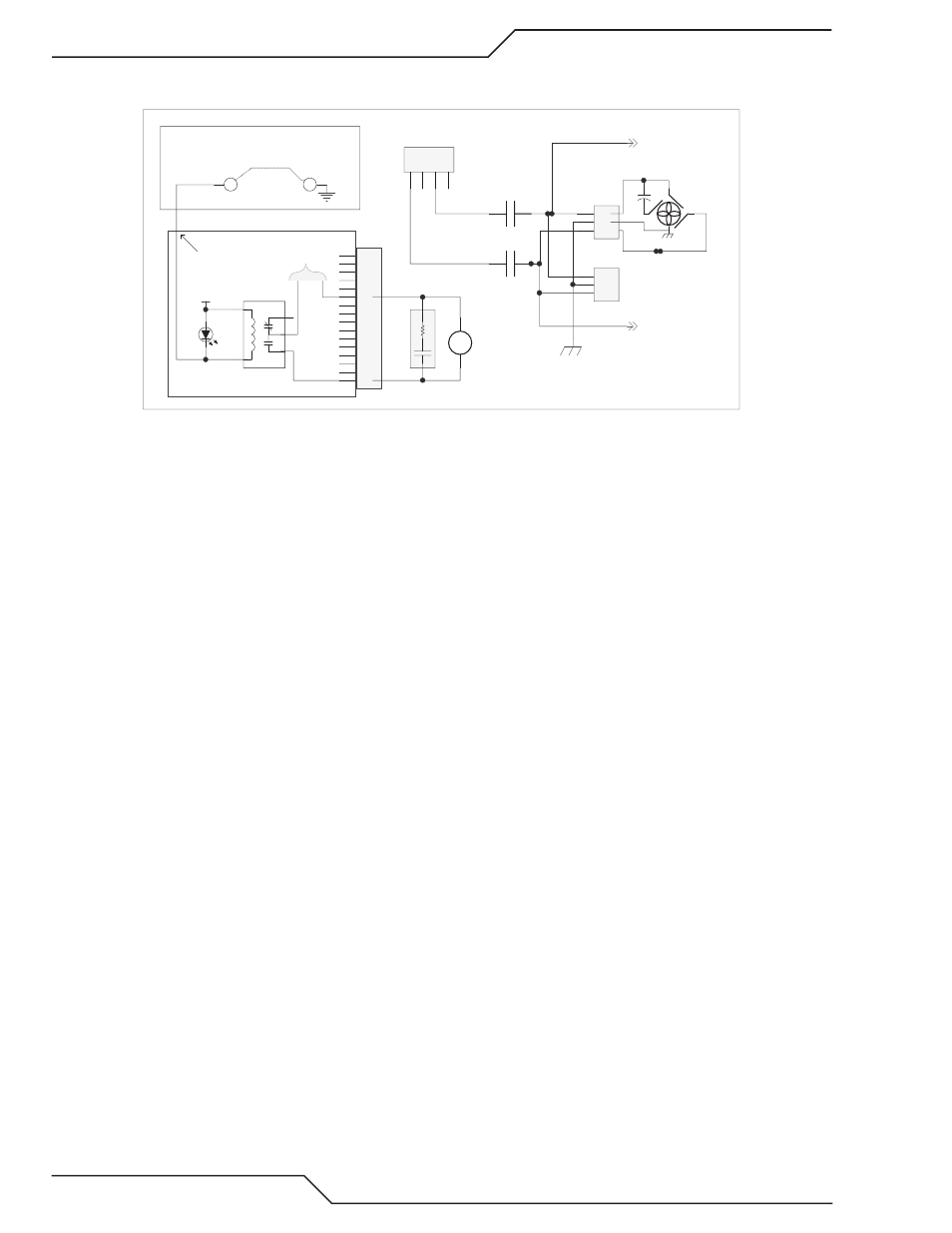

�. Fans are powered by �30 VC. The �30 VC for the fan(s) is switched by the MC� control relay (except the

C �00 XT where the fan(s) is powered directly from the T1 transformer at J13).

Art # 12311

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

J8

1

5

3

2

4

Fan Bias Control

K4

MC2

Fan Control

(160)

(161)

SA3

ARC_SUPPRESSOR

D24

24 VAC

Relay PCB

230 VAC from T1

MC2A

MC2B

To J70-2

To J70-3

(69)

(70)

(70)

(65A)

(70)

(69)

1

2

3

J73

(64A)

CHASSIS GND

1

2

3

J72

C4

FAN1

R

R

BK

BN

BL

1

2

3

4

J13

TP1

TP2

CCM I/O PCB

To test fan relay jump TP2 to TP1.

+24

J4-19

3. Check for �30 VC at either of the fan connectors, J7� & J73. It may also be measured at the rear panel con�

nector J70 for the HE�00XT fan.

a. If the fans are not getting �30 VC, measure for �� VC on the coil of MC�. If present and the relay

contacts aren’t closed the relay is defective. Note, the coil is rectified so you won’t measure continuity

of even a good coil.

b. If �� VC is not on the MC� coil check for D�� on the relay board being ON. If it’s on, the Relay board

should be providing the �� VC so if it’s not the Relay board must be defective.

c. If D�� is not on, measure on the CCM I/O board between TP� and the common at TP1. It should be low,

near zero volts. If not the CCM is probably defective. Jumper TP� (I/O board) to TP1. If the fans now

come on replace the CCM.

d. If jumping TP� to TP1 does not turn the fans on then the Relay board or the �0 pin ribbon cable pin 19

is at fault.

404

Coolant System Not Ready

When power is applied to the system with External Plasma Enable satisfied and Plasma Power Supply Enabled

(switch on �010 or TSC 3000), assuming there is enough coolant in the tank, after some initial tests taking about

15��0 seconds (see manual section � for details of the Start�Up Sequence) the pump will start. Coolant will be

pumped through the system. Flow is measured by the FS1 flow switch placed in the torch coolant return path

just before the radiator (see plumbing diagram). If the flow doesn’t reach at least 0.75 GPM (�.8 lpm) within

� minutes it will set the �0� fault. The reason for the � minutes is a new dry system especially one with long

torch leads will take some time before the leads, hoses, radiator and cold plates are full of coolant. More coolant

may have to be added. On a system that has been run before it normally takes only a few seconds to establish

proper flow. In any case the pump will run for � minutes before setting the �0� fault.

First determine if the pump motor is running and if so is there any coolant flowing. With the right lower side

panel removed touch the pump and feel for vibration to indicate if the motor is running. Observe the clear

coolant hoses to see if they are full of coolant. There are two hose fittings on the back of the tank. The upper

one is the coolant return. Remove the tank filler cover. You should see a fairly strong stream of coolant from

that fitting. The lower fitting is from the pump bypass valve. If the pump is operating some coolant may be

exiting that fitting as well. If these fittings are below the coolant level you may have to drain out some of the

coolant to see this. If a strong stream is exiting the bypass (lower) fitting but nothing from the upper fitting,

you probably have some kind of blockage.