Ultra-cut 300 xt, 07 power supply status codes – Tweco 300 XT Ultra-Cut Plasma Cutting System User Manual

Page 77

ULTRA-CUT 300 XT

Manual 0-5274

OPERATION

4-13

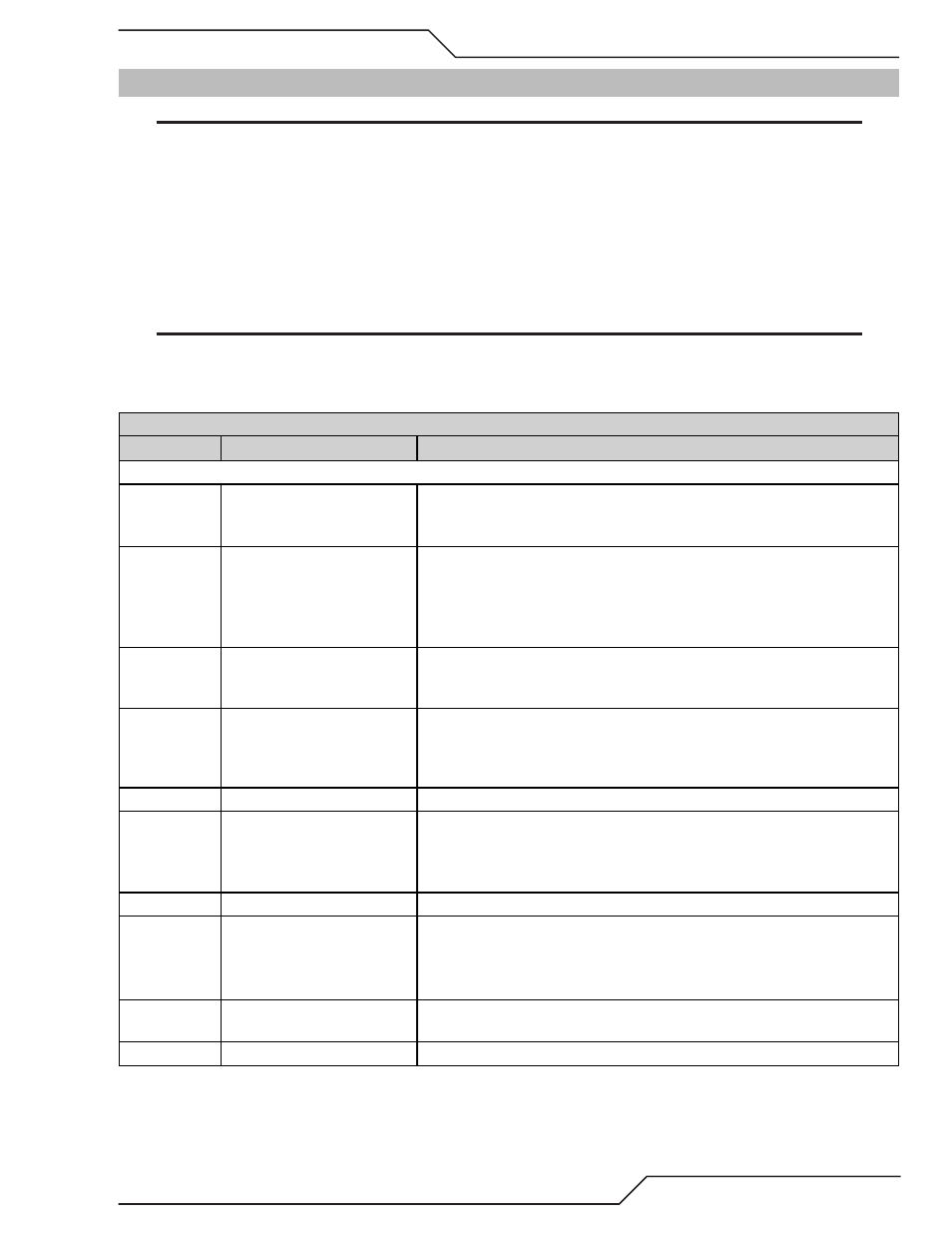

4.07 Power Supply Status Codes

NOTE

See the Appendix for Advanced Troubleshooting

On start-up and during operation, the power supply control circuitry performs various tests. If the circuitry detects

a condition requiring operator attention, the status display on the front panel shows a 3 digit number code preceded

by either letter “E” (currently active fault) or letter “L” (last or latched fault) meaning a fault occurred stopping the

process but is not currently active.

Some conditions can be active indefinitely, while others are momentary. The power supply latches momentary

conditions; some momentary conditions can shut down the system. The indicator may show multiple conditions

in sequence; it is important to recognize all possible conditions that may be displayed.

NOTE

There are no Group 5 (500) numbered status codes with the GCM 2010 system. These tables cover units

up to 400A, Lower current units won’t have all the inverter sections referred to in the Group 2. However

codes for those sections should not appear.

CCM Status Code

Code

Message

Remedy / Comments

Group 1 -- Plasma Process

101

Plasma Disabled

Plasma Enable Off ; Disable activated on GCM 2010 or external SW disabled

(CNC); CCM TB1-1&2 jumper missing; 40 circuit ribbon cable from Relay

PCB to CCM disconnected or defective;

102

Pilot Ignition Failure

Pilot did not start within 15 seconds. Torch consumable parts worn? Ensure

correct process selected or manual setting including current control setting

matches consumables; Plasma pressure too high; Defective Arc Starter;

Defective Pilot PCB; defective Inverter section 1A. Ribbon cables reversed on

INV1 sections 1A and 1B.

103

Lost Pilot

Pilot went out while Start active. Torch consumable parts worn? Ensure cut

process or current control setting setting matches consumables; Plasma

pressure too high;

104

Transfer Lost

Arc was transferred to work then went out while Start still active. Arc lost

contact with work (run off edge, over hole, etc.); Standoff too high; Ensure

cut process or manual settings (current control, gas pressures) matches

consumables;

105

Not used

Reserved for legacy product

106

Pilot Timeout, no Transfer

Must transfer from Pilot to Cutting Arc in 0.085 seconds (SW8-1 OFF) or 3

sec. (SW8-1 ON). Standoff too high or void in work under torch; Wrong cut

process selected or wrong manual settings (current control set too low or

wrong gas pressure).

107

Not used

Reserved for legacy product

108

Tip to Electrode voltage fault.

Tip voltage too close to electrode voltage; Torch consumable parts worn out;

Wrong consumables installed causing tip to electrode short; Wrong process

selected or wrong manual setting of plasma gas or cutting current.; Leak in

Plasma hose to torch; Defective Pilot PCB; Shorted torch body .

109

Part process not configured. Applies only to DFC 3000 Auto Gas Control. Select and load a cutting pro-

cess.

110

Not used

Reserved for legacy product