Section 3: installation, 1 common devices installation, Section 3: installation -1 – Tweco iCNC XT User Manual

Page 21: Common devices installation -1, Icnc xt

iCNC XT

Manual 0-5299

INSTALLATION

3-1

SECTION 3: INSTALLATION

3.1 Common Devices Installation

WARNINGS

DO NOT CONNECT the main power before all wiring is done and all cables are connected at both ends.

Always follow national wiring standard for wire sizes.

This section provides a basic wiring guide for limit switches, E-stops, Yaskawa drives, Down draft control and laser pointer. If you have a dif-

ferent type of setup and are unsure how to wire your machine please contact Victor Technologies for further support.

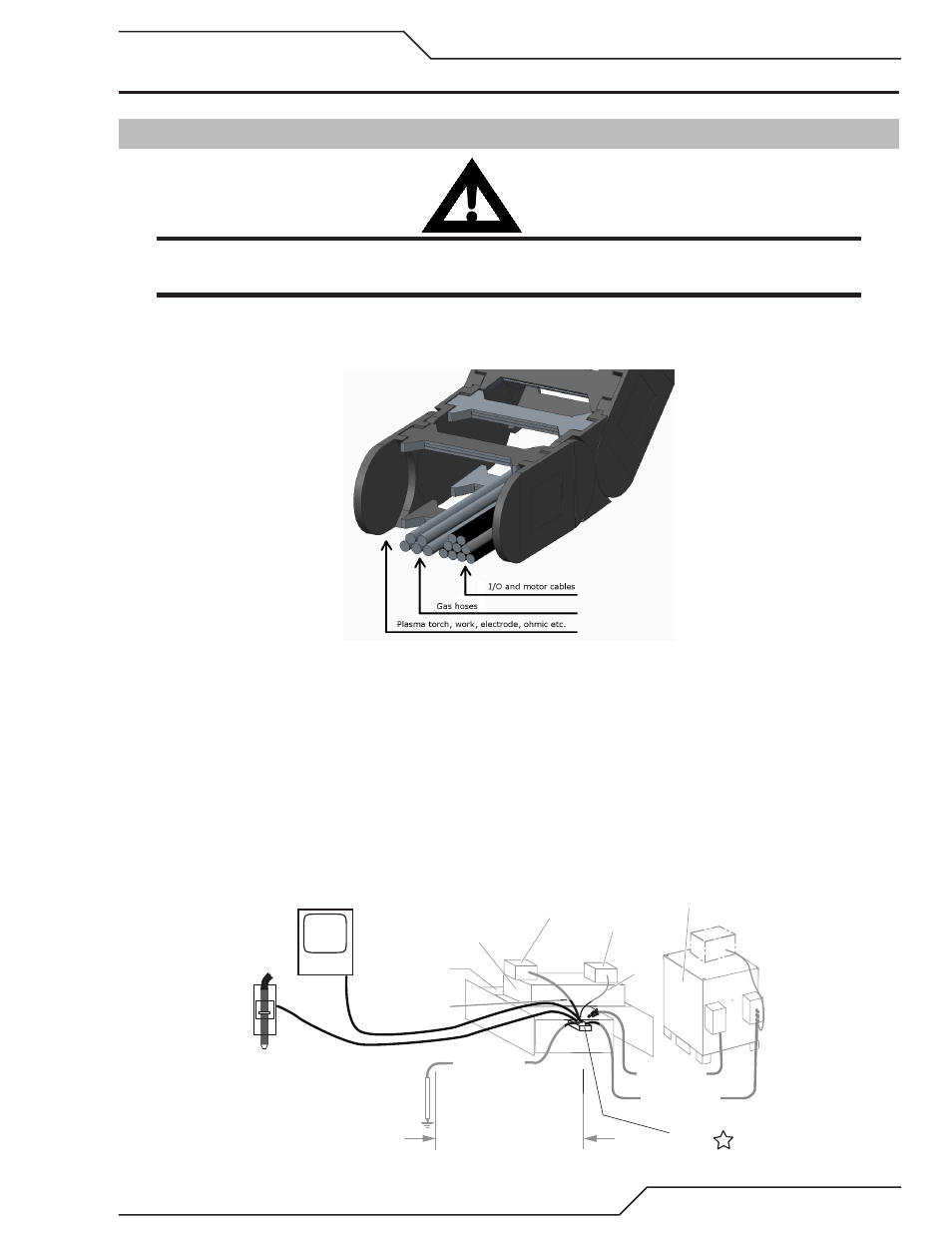

Grounding Requirements

Creating an Earth Ground

1. To create a solid, low resistance, earth ground, drive a 12 mm (1/2 in) or greater diameter copper clad ground rod at least 1.8 - 2.4m (6

- 8 ft) into the earth so that the rod contacts moist soil over most of its length. Depending on location, a greater depth may be required

to obtain a low resistance ground. Ground rods, typically 3m (10 ft) long, may be welded end to end for greater lengths. Locate the

rod as close as possible to the work table. Install a ground wire, 50mm² (1/0 AWG) or greater, between the ground rod and the star

ground point on the cutting table.

0 - 10 ft (0 - 3 m) Ideal

20 ft (6 m) Maximum

1/0

Ground Cable

Power Supply

‘Star’

Ground

Earth Ground

Rod

XT CNC

Controller

Lifter

Cutting Table

Cutting Machine / Gantry

Work Cable

Remote Arc

Starter

Star Ground on Cutting Table

Gas Control Module

Primary location

#4 AWG

Ground

(F)

Customer supplied

1/0

Ground Cable

(F1)

... . .. .

.. .. ..

Ground Cable