Tweco 100 Auto-Cut User Manual

Page 65

Manual 0-4764

4-5 OPERATION

Top-Edge Rounding

Rounding on the top edge of a cut due to wearing from the initial contact of the plasma arc on the workpiece.

Dross Build-up and Top Spatter

Dross is molten material which is not blown out of the cut area and re-solidifies on the plate. Top spatter

is dross which accumulates on the top surface of the workpiece. Excessive dross may require secondary

clean-up operations after cutting.

Kerf Width

The width of material removed during the cut.

Nitride Build-up

Nitride deposits which may remain on the cut edge of the carbon steel when nitrogen is present in the

plasma gas stream. Nitride buildups may create difficulties if the steel is welded after the cutting process.

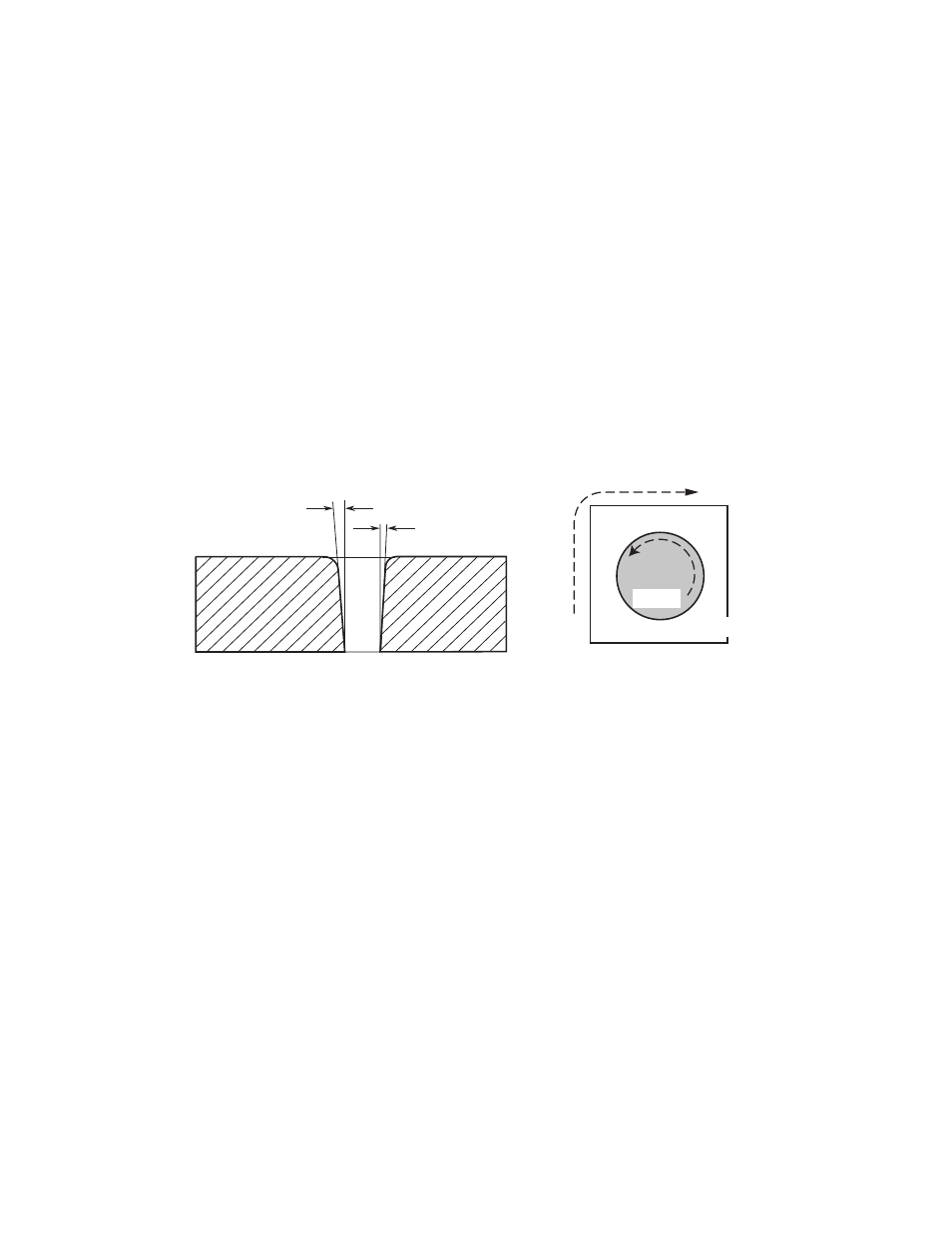

Direction of Cut

The plasma gas stream swirls as it leaves the torch to maintain a smooth column of gas. This swirl effect

results in one side of a cut being more square than the other. Viewed along the direction of travel, the right

side of the cut is more square than the left.

Right Side

Cut Angle

Left Side

Cut Angle

A-00512

Scrap

Clockwise

Counter-

Clockwise

Art # A-04182

Workpiece

Scrap

Swirl Effect on Side Characteristics of Cut

To make a square - edged cut along an inside diameter of a circle, the torch should move counterclockwise

around the circle. To keep the square edge along an outside diameter cut, the torch should travel in a clock-

wise direction.

Underwater Cutting

Cutting on a water table either underwater or with the water touching the plate or with a water muffler

system is not recommended. If a water table is used the water level must be a minimum of 4 inches from

the bottom of the plate. Failure to follow this recommendation could result in poor cut quality and short

consumable parts life.

Ohmic Sensing

Ohmic height sensing is not recommended with water shield. Water on the plate interferes electrically with

the ohmic sensing circuit.