04 cut quality, Cut quality -4 – Tweco 100 Auto-Cut User Manual

Page 64

OPERATION 4-4

Manual 0-4764

J. Pressure and Flow Settings

1. Refer to the Torch manual for pressure and flow details according to the material being cut. Move the RUN/

SET switch to SET position. (Gas will flow through the torch). Set gas pressures and flows as follows:

2. To set the Plasma Gas pressure:

a. Pull out the knob on the Plasma Gas pressure control knob.

c. Turn the knob to adjust gas pressure.

d. Push the knob back in to lock the pressure setting.

3. To set the Shield Gas pressure: Set the Shield Mode Selector switch to the GAS or H

2

O MIST position.

For Gas Shield:

a. Pull out the Shield Gas Pressure Control Knob.

c. Turn the knob to adjust gas pressure.

d. Push the knob back in to lock the pressure setting.

For H

2

O MIST Shield:

a. Turn the Water Mist Control Knob to adjust pressure.

b. Push the knob back in to lock the pressure setting.

NOTE

Unless the installation includes gas selection equipment between the gas supplies and the control console, switching

between gases requires disconnecting the gas supply line(s) from the control console rear panel and connecting

the appropriate input gases. Water input can remain connected permanently because the shield selector switch

disables and enables the flow of water for H

2

O Mist shield.

4. Place the RUN/SET switch to the RUN position.

4.04 Cut Quality

Cut quality requirements differ depending on application. For instance, nitride build-up and bevel angle may

be major factors when the surface will be welded after cutting. Dross-free cutting is important when finish cut

quality is desired to avoid a secondary cleaning operation. Cut quality will vary on different materials and

thicknesses.

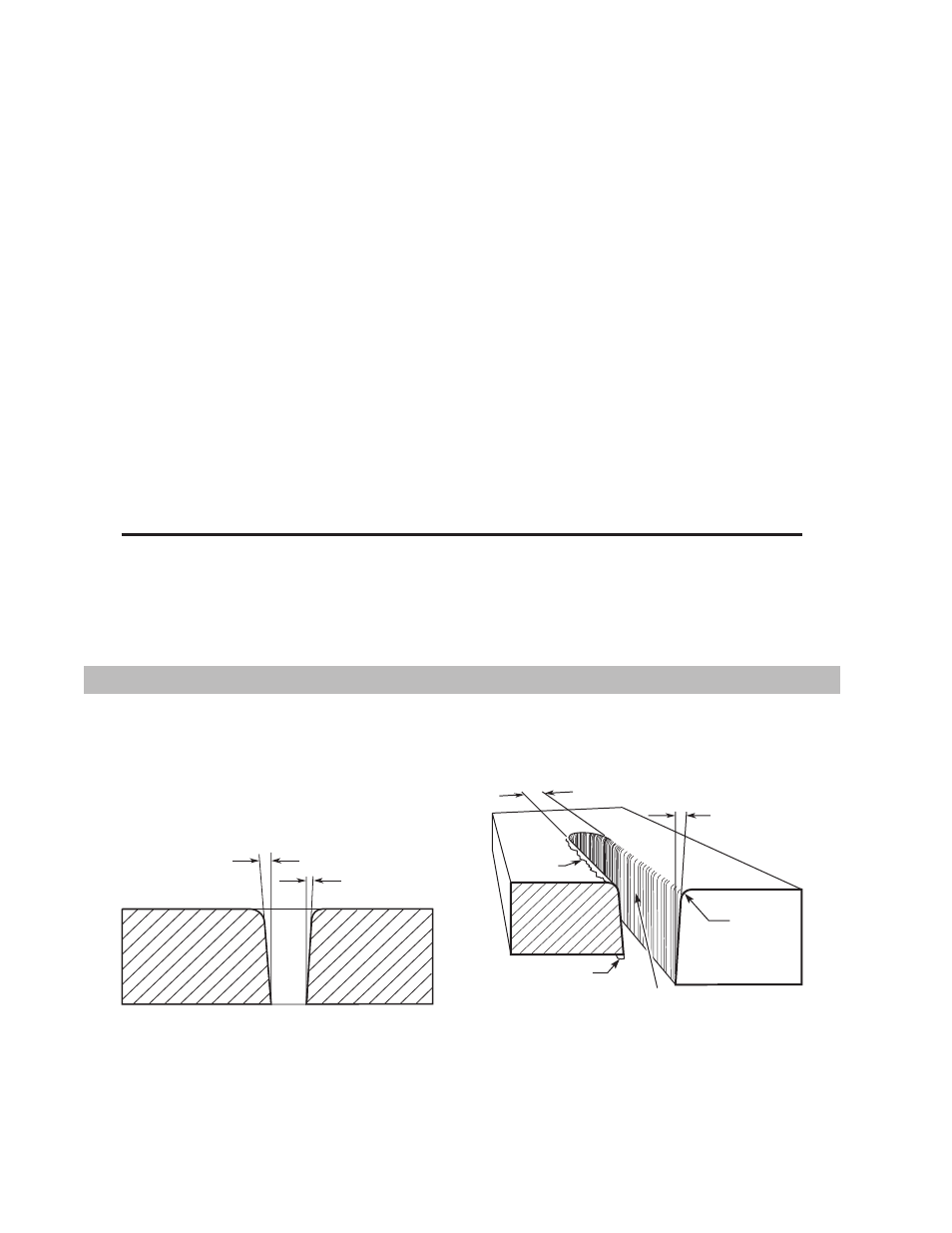

Right Side

Cut Angle

Left Side

Cut Angle

A-00512

Kerf Width

Cut Surface

Bevel Angle

Top Edge

Rounding

Cut Surface

Drag Lines

Dross

Build-Up

Top

Spatter

A-00007

Cut Surface

The condition (smooth or rough) of the face of the cut.

Bevel Angle

The angle between the surface of the cut edge and a plane perpendicular to the surface of the plate. A per-

fectly perpendicular cut would result in a 0° bevel angle.